Gearbox motor straight rotating device for electric motorcycle tricycle and driving method thereof

A technology of electric motorcycles and rotating devices, which is applied in the direction of vehicle gearboxes, wheel transmissions, and rotary transmissions. non-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

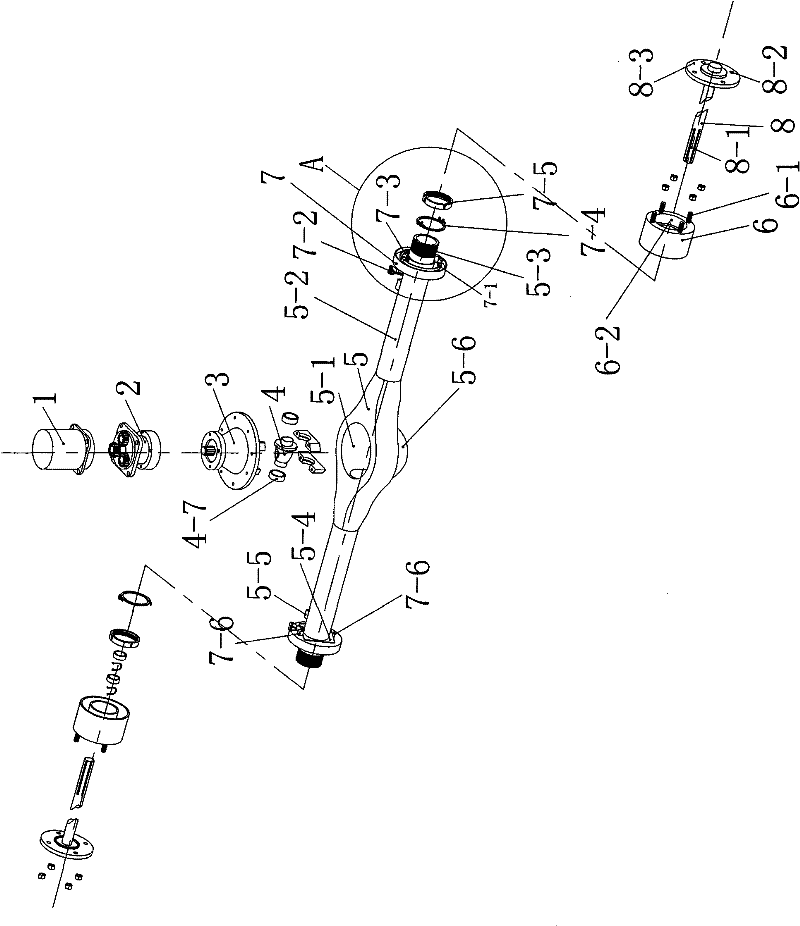

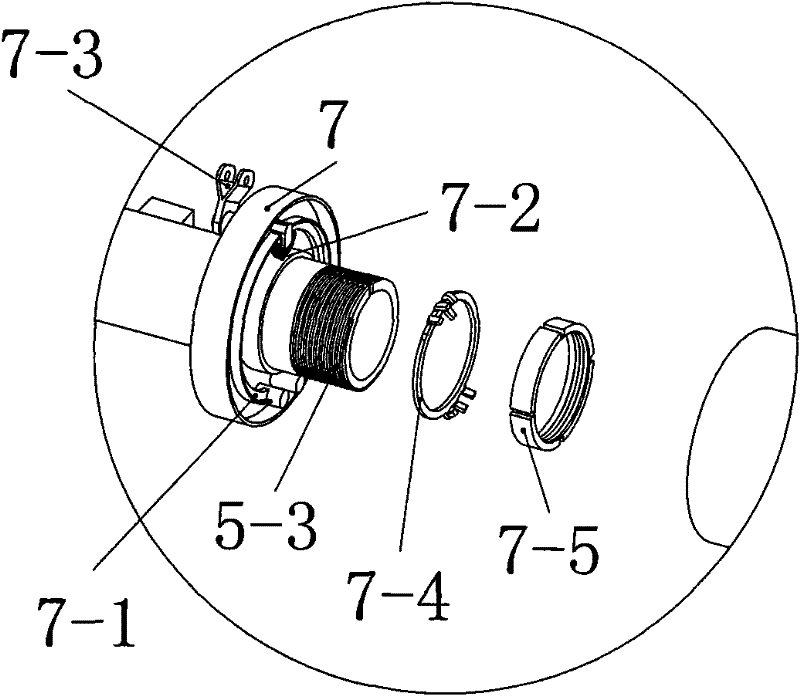

[0041] The structure and usage of the present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 5 As shown, in the present invention, the motor 1 bottom is provided with pits, and the side of the pit is provided with a ring gear 1-1, and the center of the pit is fixedly connected with a central gear 1-2, and the side of the motor is provided with a motor end cover 1-3. The end cover is provided with motor end cover through holes 1-4; the motor starts to drive the central gear to rotate on the surface parallel to the motor end cover.

[0042] Such as Figure 6-10 As shown, the planetary gearbox assembly 2 includes a planetary gearbox assembly shell 2-1 and a turntable shaft 2-7; the shape of the planetary gearbox assembly shell is a rounded cube and a large cylinder with an irregular cylinder in the middle , The shell of the planetary gearbox assembly is hollow inside, the rounded cube is provided with a through hole 2-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com