Following wake tube of ship

A ship and wake technology, applied in the field of wake tubes, can solve problems such as insufficient recovery and utilization of energy, reduced propulsion efficiency of the propulsion system, and increased wave-making resistance at the stern, so as to improve hull efficiency and propulsion Efficiency, optimized layout, effect of improved flow field in the stern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

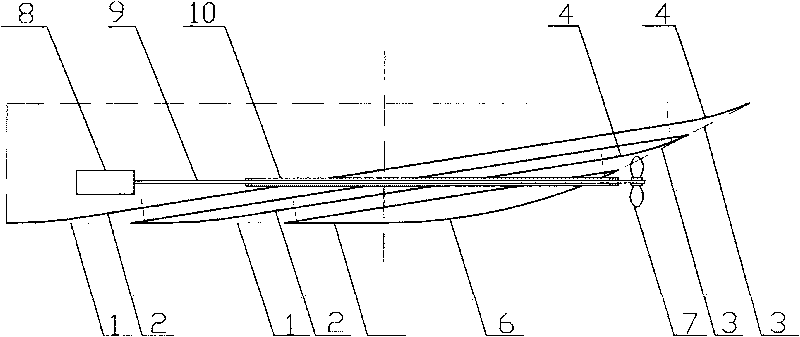

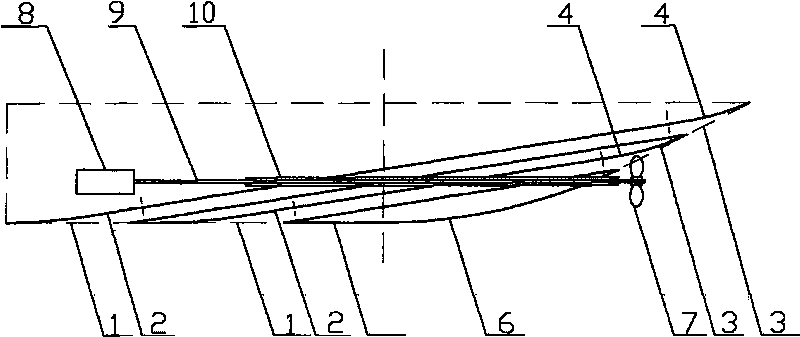

[0039] Such as figure 1 As shown, the wake pipe of the ship with water outlet in front of the propeller and behind the side. The center line of the follower pipe is on the same water plane (or longitudinal section), the water inlet 1 of the follower pipe is on the side deck (or bottom surface) 5 of the midship part of the ship, and the water outlet 3 of the follower pipe It is on the side surface (or bottom surface) 6 of the stern, the inlet part 2 of the follower tube and the outlet part 4 of the follower tube are both bell-shaped, and the transmission shaft 9 of the propeller 7 and its shaft tube 10 pass through the follower tube. The tip circle of the propeller 7 passes through the bell mouth of the outlet part 4 of the relevant tracer pipe, and the front end of the transmission shaft 9 is the electric motor or gearbox 8 .

[0040] As the ship advances, its stern decompresses and creates waves. Under the effect of negative pressure difference, part of the wake in the mids...

Embodiment 2

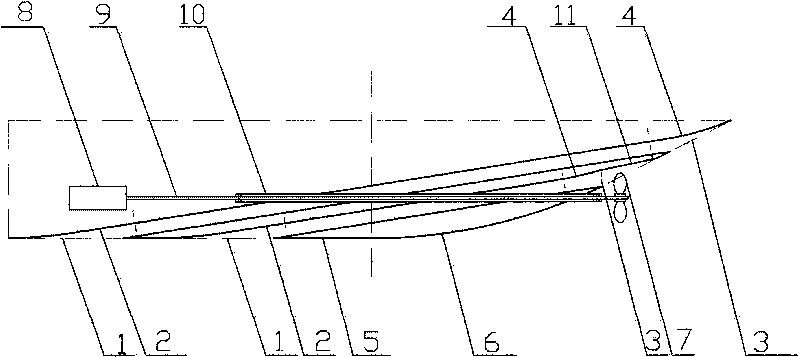

[0043] Such as figure 2 As shown, the ship waker pipe and its dustpan-shaped concave surface near the water outlet. The center line of the follower pipe is on the same water plane (or longitudinal section), the water inlet 1 of the follower pipe is on the side deck (or bottom surface) 5 of the midship part of the ship, and the follower pipe in front of the propeller 7 The water outlet 3 is on the steep slope in front of the pit formed by the dustpan-shaped concave surface 11, the water outlet 3 of the follower pipe behind the propeller 7 side is on the outside of the rear of the pit, and the inlet part 2 of the follower pipe and the outlet part 4 of the follower tube are bell-shaped, the drive shaft 9 of the propeller 7 and its shaft tube 10 pass through the follower tube, the tip circle of the propeller 7 passes through the pit, and the front end of the drive shaft 9 is a motor or speed changer. Box 8.

[0044] Compared with the first embodiment, this embodiment is basical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com