Combined conveyor

A technology of conveyors and conveying devices, which is applied to conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of large footprint and complicated operation, and achieve the effects of small footprint, simple maintenance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

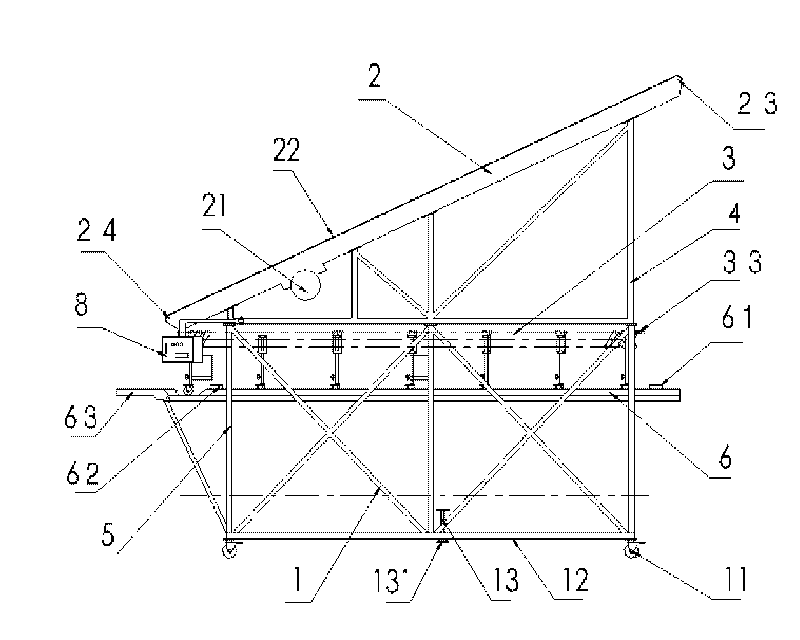

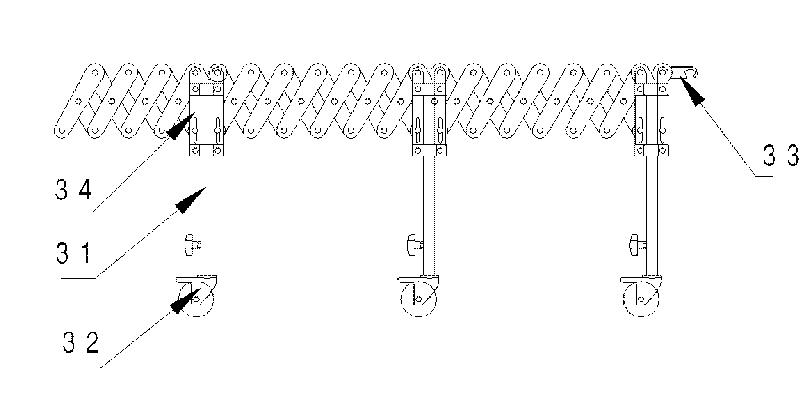

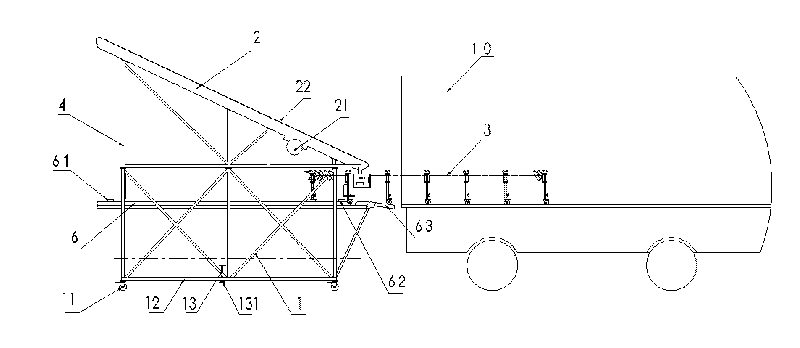

[0027] Embodiment 1: as Figure 1~3 As shown, a combined conveyor is provided with an inclined plane conveying device 2 and a horizontal conveying device 3 on the upper part of the frame 1. The inboard of pole 4,5 is provided with slide rail 6, and the following of horizontal conveying device is provided with telescopic mechanism, and telescopic mechanism comprises some root supporting legs 31 that are provided with below it, and each supporting leg is all provided with roller 32 below, and roller can Roll along the slide rail 6 on the frame, so that the horizontal conveying device can extend or retract on the support 1; the legs are made of square steel pipes, connected with the horizontal conveying device by a splint device 34, and the splint is locked with screws. The height of the horizontal conveying device can be adjusted by adjusting the position of the legs in the splint device. The high-end end 23 of the inclined-plane conveying device can be against the position of ...

Embodiment 2

[0036] Embodiment 2: the inclined plane conveying device of embodiment 1 is connected with the described struts at the high and low ends with hinges 40 and 50 respectively, and the struts 4 at the high end are connected with height-adjustable screw rods Structure, adjust the height of the high end 23 of the inclined plane conveying device with a two-way nut 41 and then lock it with a nut 42.

[0037] In the present invention, the inclined-plane conveying device and the horizontal conveying device are integrated, and the inclined-plane conveying device and the frame of the truss structure are connected together, so that the strength is high, the rigidity is strong, and it is durable; when in use, it is only necessary to adjust the horizontal conveying machine relative to the compartment of the container truck The introduction depth is simple and easy to operate; the parallel four-bar mechanism is used as the telescopic transmission mechanism for the horizontal conveying device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com