Self-disassembling device of tower crane

A tower crane, self-disassembly technology, applied in the direction of cranes, etc., can solve the problems of restricting the use environment of tower cranes, empty workplaces, etc., to achieve good economic benefits, save costs and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

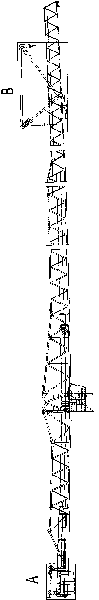

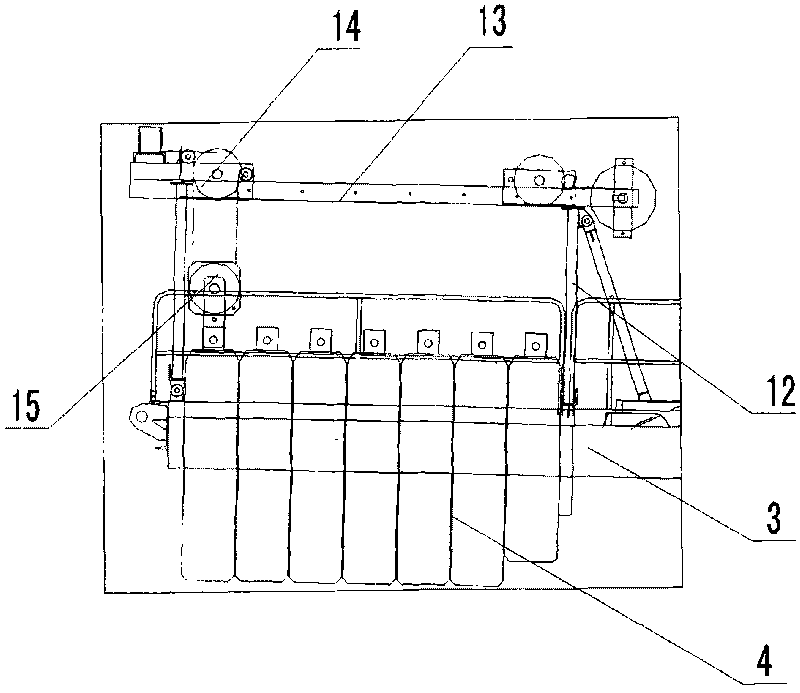

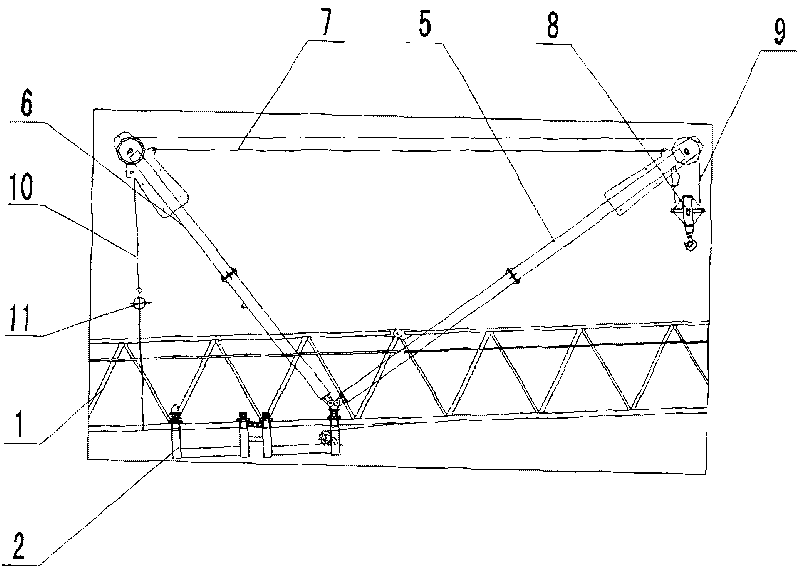

[0010] The tower crane self-detachment device includes a self-detachment jib device installed on the jib 1 and a self-detachment counterweight device installed on the balance arm 3 . The self-disassembling jib device is a mast-type lifting frame. The lower ends of the front mast 5 and the rear mast 6 are hinged on the luffing trolley 2 under the jib. The upper ends of the two masts 5 and 6 are connected by wire ropes 7. 5. There is a hook 8 connected to the lifting wire rope 9 at the front end; a manual hoist 11 connected by a wire rope 10 is arranged at the rear end of the rear mast 6. After the installation of the self-detachable boom device is completed, it can walk on the boom 1 with the luffing trolley 2. When disassembling, move the luffing trolley 2 to the last section of the jib to be removed, and then connect the wire rope 10 to the bottom of the jib 1 through the hand chain hoist 11, so that the luffing trolley 2 is fixed at this position Move, can carry out dismount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com