Cover open-close device of lubricating pot

A technology for opening and closing devices and can lids, which is applied in the direction of packaging, transportation and packaging, bottle/container lids, etc. It can solve the problems of affecting the service life of lubrication tanks, troublesome opening methods for prying, and easily damaged can lids, etc., to achieve operation Ease of use, smooth operation, and time-wasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

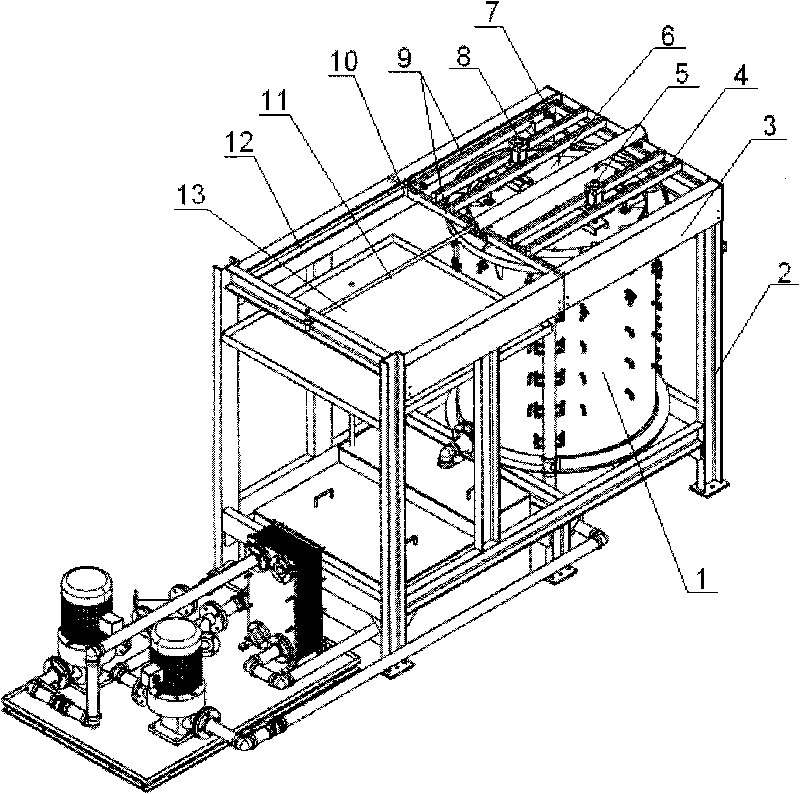

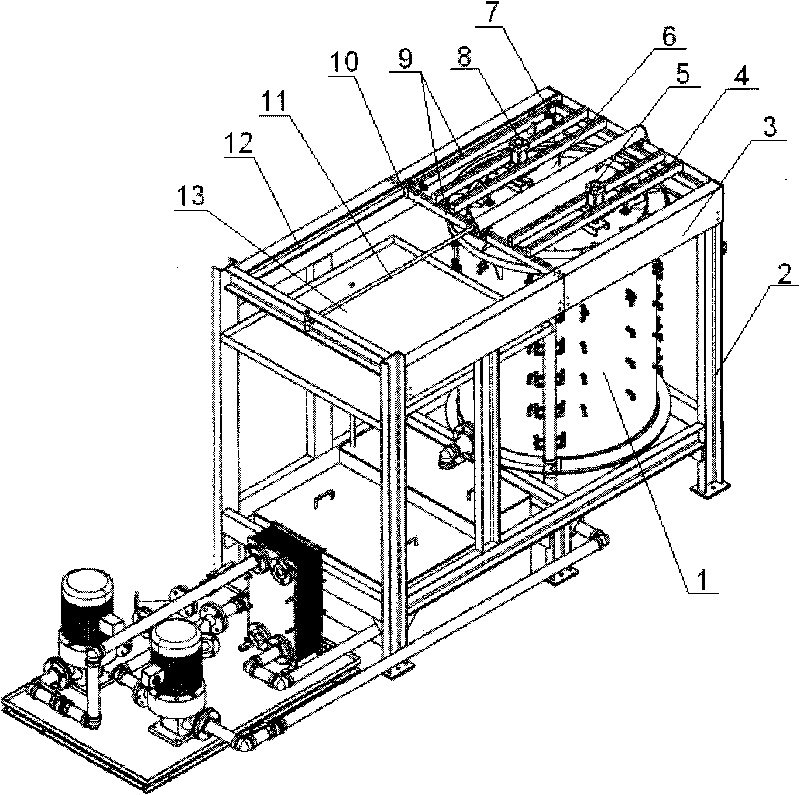

[0019] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0020] As shown in the accompanying drawings, the present invention discloses a lid opening and closing device for a lubrication tank, which includes a bracket 2 forming a cuboid, and the bracket 2 includes at least six edges of the cuboid. A square mobile frame 9 is installed on the top of the support 2 , and the edge of the mobile frame 9 is attached to the support 2 . The size of the rectangle at the top of the support 2 is preferably equivalent to the size of two moving frames 9 arranged in parallel, and the size of the moving frame 9 is preferably inscribed in the outer circle of the tank cover 6 .

[0021] The two long sides 3 at the top of the bracket 2 are provided with transverse guide rails 12 . The two long sides 3 at the top of the support 2 are widened in the longitudinal direction, and longitudinal guide rails 10 are arranged on the inner side corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com