Rubbery composition for tire tread

A technology of rubber composition and tire tread, applied in special tires, tire parts, optimization of rolling resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~5

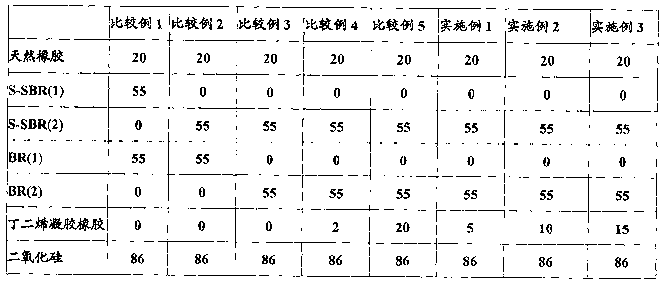

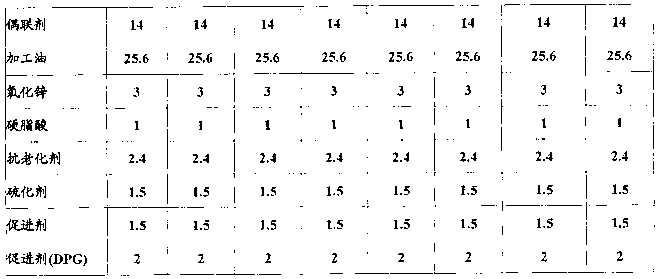

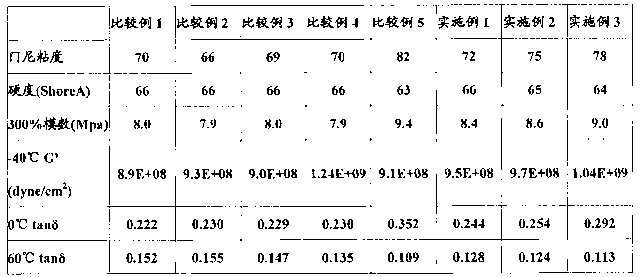

[0047] Using the compositions shown in Table 1 below, tire rubber compositions of Examples 1 to 3 and Comparative Examples 1 to 5 were prepared. The tire rubber composition is produced by a usual tire production method.

[0048] [Table 1] (parts by weight)

[0049]

[0050]

[0051] 1. Natural rubber: rubber obtained from nature, the chemical name is polyisoprene.

[0052] 2. S-SBR (1): solution-polymerized styrene-butadiene rubber (SBR) produced by a batch process with a styrene content of 24% by weight and a vinyl content in butadiene of 66% by weight.

[0053] 3. S-SBR (2): A solution-polymerized styrene-butadiene rubber (SBR) produced by a continuous process with a styrene content of 24% by weight and a vinyl content in butadiene of 66% by weight.

[0054] 4. BR (1): Nickel butadiene rubber manufactured by Kumho Petrochemical Co., Ltd., trade name KBR01.

[0055] 5. BR (2): Neodymium butadiene rubber manufactured by Lanxess Co., Ltd., trade name is CB29MES.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com