Thermal interface material and using method thereof

一种热界面材料、热源的技术,应用在传热改性、热交换设备、半导体/固态器件零部件等方向,能够解决导热颗粒难以熔融、导热系数下降、影响热界面材料导热系数等问题,达到降低界面热阻、优异导热性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

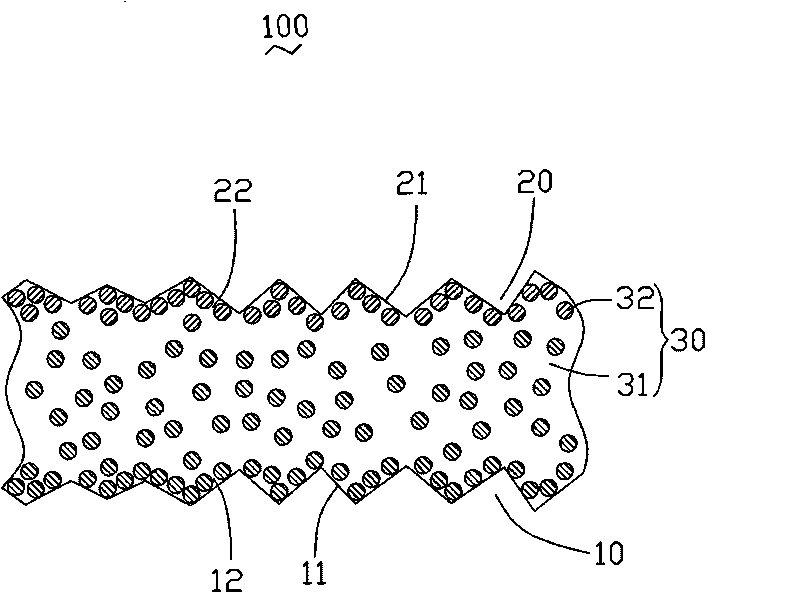

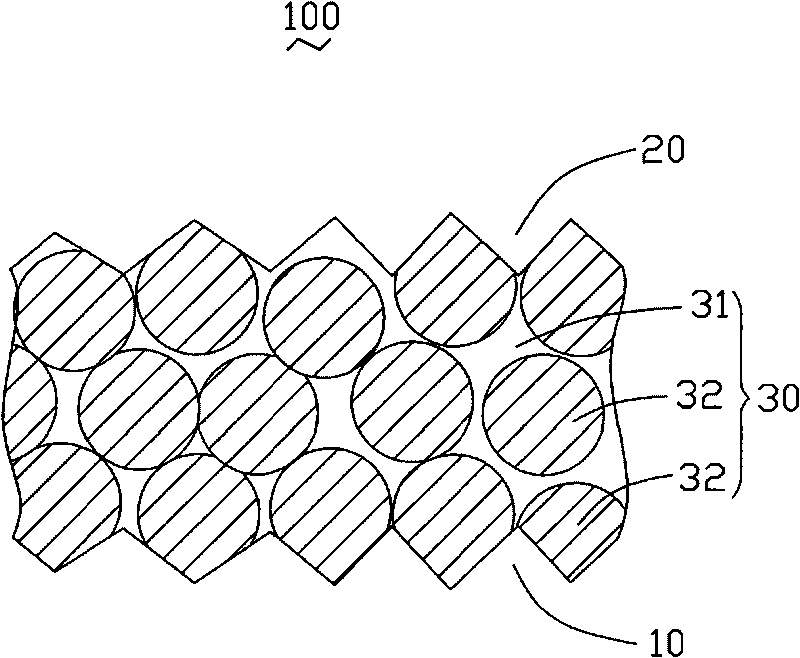

[0016] The thermal interface material and the method of using the thermal interface material according to the embodiment of the present invention will be further described in detail below with reference to the accompanying drawings.

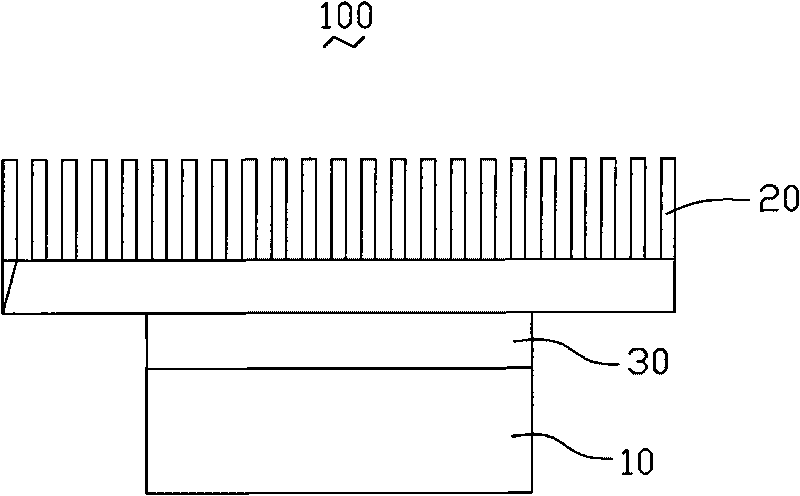

[0017] see figure 1 and figure 2 , is a schematic diagram of the application of the thermal interface material 30 provided by the first embodiment of the present invention. During practical application, the thermal interface material 30 is disposed between a heat source 10 and a heat dissipation device 20 for transferring heat from the heat source 10 to the heat dissipation device 20 . The heat source 10 , the heat sink 20 and the thermal interface material 30 together form an electronic device 100 .

[0018] The heat source 10 may be a semiconductor integrated device, or an IC circuit, a resistor or other heating elements. The heat source 10 has a protection temperature T1 that prevents the heat source 10 from being damaged by overheating. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com