Preparation method of cationic heat-absorbing and perspiration superfine fibres

An ultra-fine fiber and cationic technology, applied in fiber processing, melt spinning, filament forming processing, etc., can solve the problems of fibers without heat absorption and perspiration, monotonous color, difficult dyeing, etc., and achieve slender hand feeling and good drape The effects of high permeability, good air permeability and dyeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

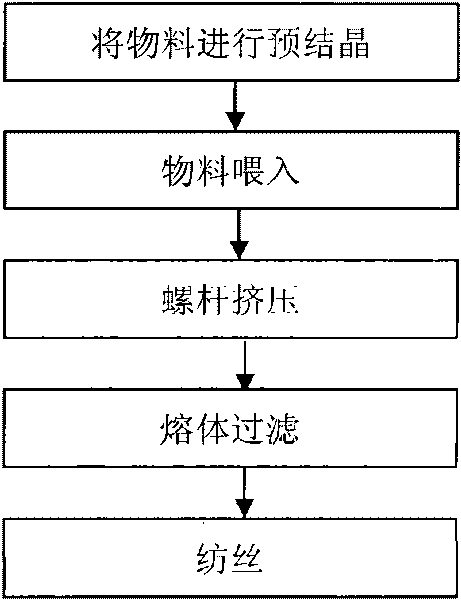

[0012] In conjunction with the accompanying drawings, a method for preparing cationic heat-absorbing and sweat-wicking superfine fibers of the present invention comprises the following steps:

[0013] Step 1. Pre-crystallize the material, and then dry it with dry hot air. The material is a cationic dye-dyeable copolymer; the pre-crystallization temperature is 170-180°C, the temperature of the dry hot air is 140-150°C, The dew point is less than or equal to -80°C, the moisture content of the material is 25ppm, and the drying time is 12 to 16 hours.

[0014] Step 2, the material is screw fed into the screw extruder:

[0015] Step 3, filter, filter the material extruded by the extruder, ensure the continuous production of spinning and the constant pressure of the screw extruder when filtering; the pre-filter pressure during filtration is less than or equal to 16Mpa, and the filter process is constant The pressure of the filter is 9Mpa, and the filter mesh of the filter used for ...

Embodiment 1

[0019] A preparation method of a cationic heat-absorbing and sweat-wicking superfine fiber method, comprising the following steps:

[0020] Step 1. Pre-crystallize the material, and then dry it with dry hot air. The material is a cationic dye-dyeable copolymer; the pre-crystallization temperature is 170°C, the temperature of the dry hot air is 140°C, and the air dew point is -80 °C, the moisture content of the material is 25ppm, and the drying time is 12 hours.

[0021] Step 2, the material is screw fed into the screw extruder:

[0022] Step 3, filter, filter the material after extruder extruding, guarantee the continuous production of spinning and the constant of screw extruder pressure when filtering; The pressure before filtering when filtering is 16Mpa, constant in the filtering process The pressure is 9Mpa, and the filter mesh of the filter used during filtration is 30 microns.

[0023] Step 4, spinning, the mixture coming out of the filter enters the spinning assembly,...

Embodiment 2

[0025] A preparation method of a cationic heat-absorbing and sweat-wicking superfine fiber method, comprising the following steps:

[0026] Step 1. Pre-crystallize the material, and then dry it with dry hot air. The material is a cationic dye-dyeable copolymer; the pre-crystallization temperature is 180°C, the temperature of the dry hot air is 150°C, and the air dew point is -78 °C, the moisture content of the material is 25ppm, and the drying time is 16 hours.

[0027] Step 2, the material is screw fed into the screw extruder:

[0028] Step 3, filter, filter the material after extruder extrusion, guarantee the continuous production of spinning and the constant of screw extruder pressure when filtering; the pre-filtration pressure during filtration is 15.5Mpa, constant in the filtration process The pressure of the filter is 9Mpa, and the filter mesh of the filter used for filtering is 30 microns.

[0029] Step 4, spinning, the mixture coming out of the filter enters the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com