Steel rail welding joint heat treatment device and heater thereof

A technology for heat treatment devices and welded joints, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of low ignition point, the research and improvement of the water cooling structure that has not been found to minimize or eliminate the heater, and the bulky heat treatment device. effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

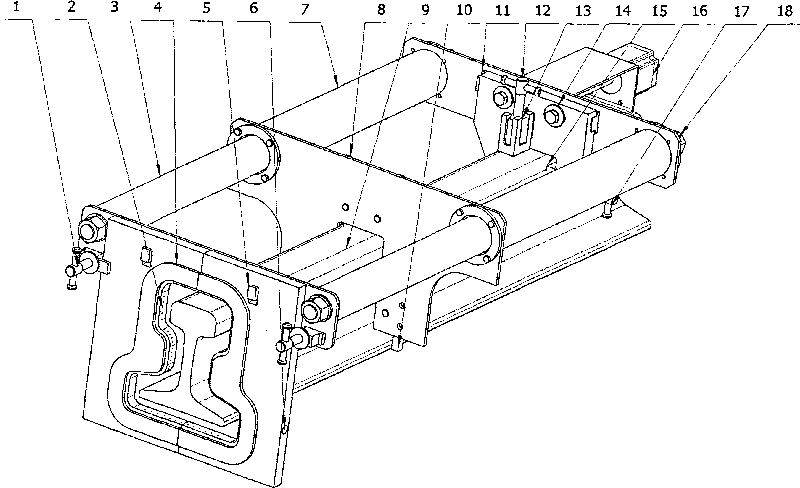

[0030] general reference figure 1 , generally shows a rail welded joint heat treatment device. The heat treatment device includes a heater 4, a support structure and a sliding mechanism (rails 3). In this embodiment, as will be described in more detail below, the support means is supported and secured to rails. A sliding mechanism having a first end and a second end is supported on the support structure and is reciprocally slidable in the direction in which the rail extends. The heater 4 is mounted on the slide mechanism, in particular on the end plate of the first end of the guide rail 3, so that the heater 4 surrounds the welded joint. For clarity, in figure 1 The complete welded joint is not shown and the rail is truncated, but it should be understood that the apparatus of the present invention can equally heat treat extended long rails.

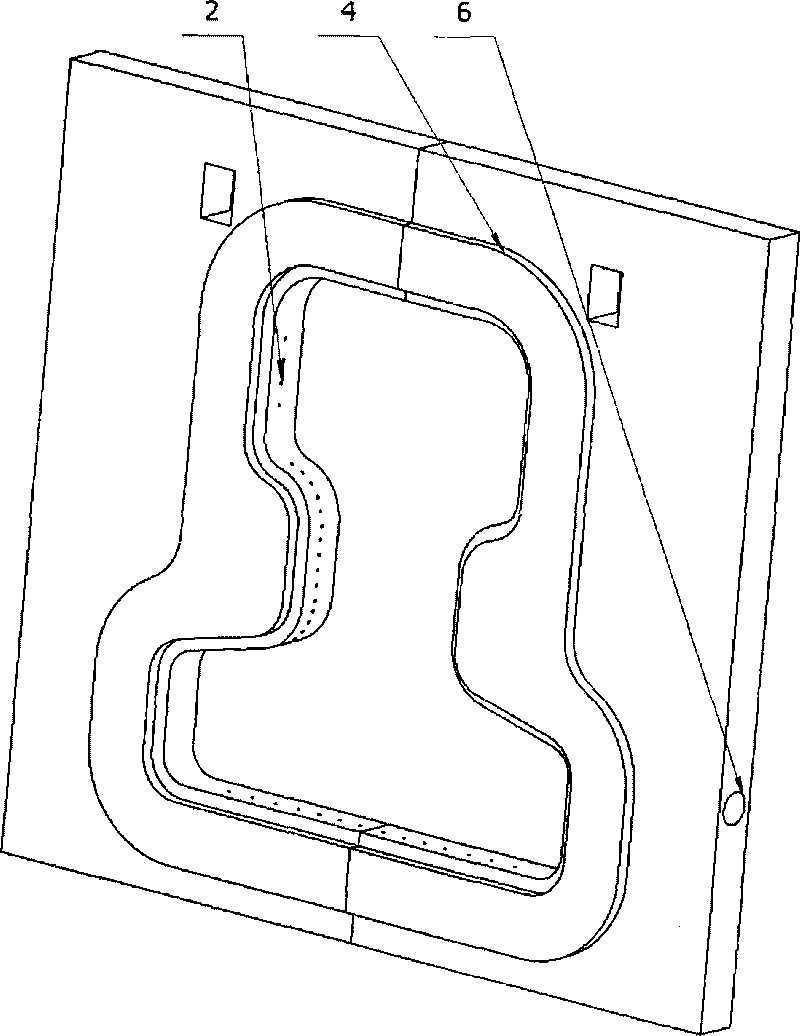

[0031] Now specific reference figure 2 , shows the design of the heater 4 that uses gas to heat the rail welded joint. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com