Direct drawing device and direct drawing method for detecting compressive strength of concrete

A compressive strength and concrete technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of surface damage of the tested concrete and lack of detection methods, and achieves low test cost, small damage surface, and detection accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

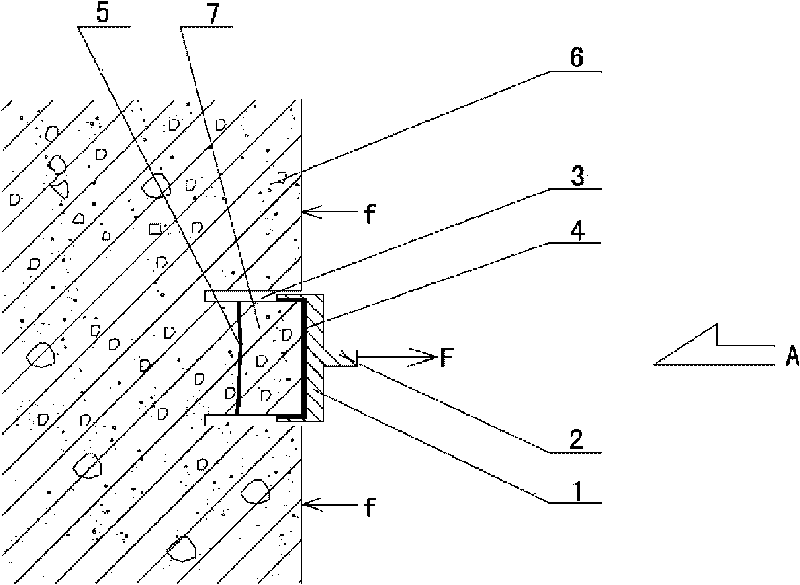

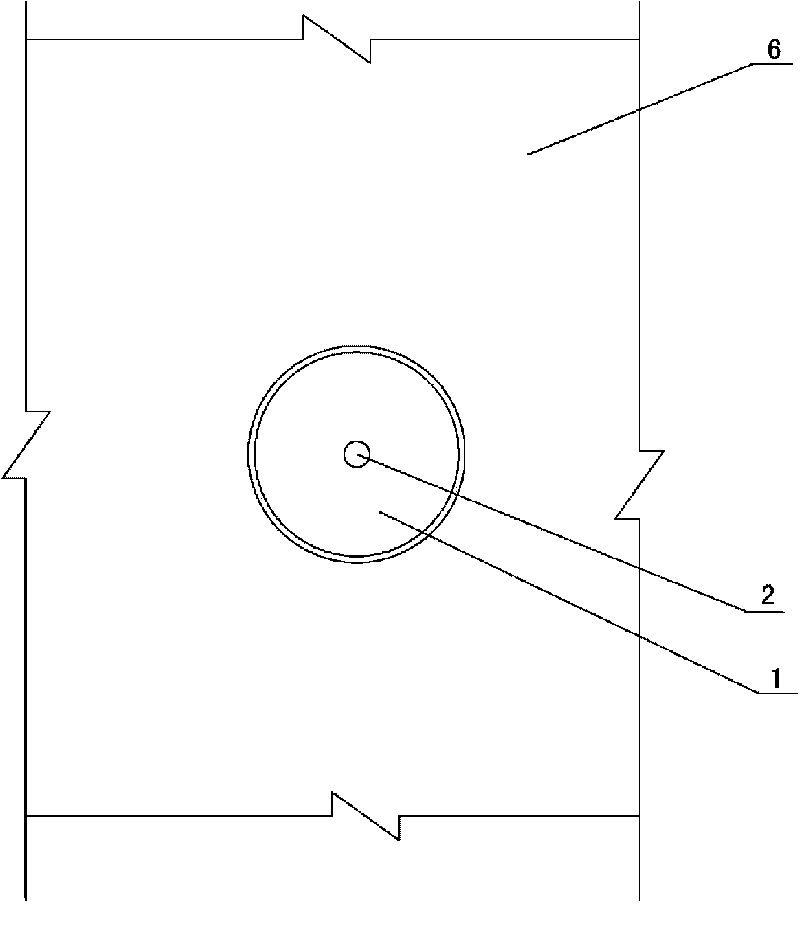

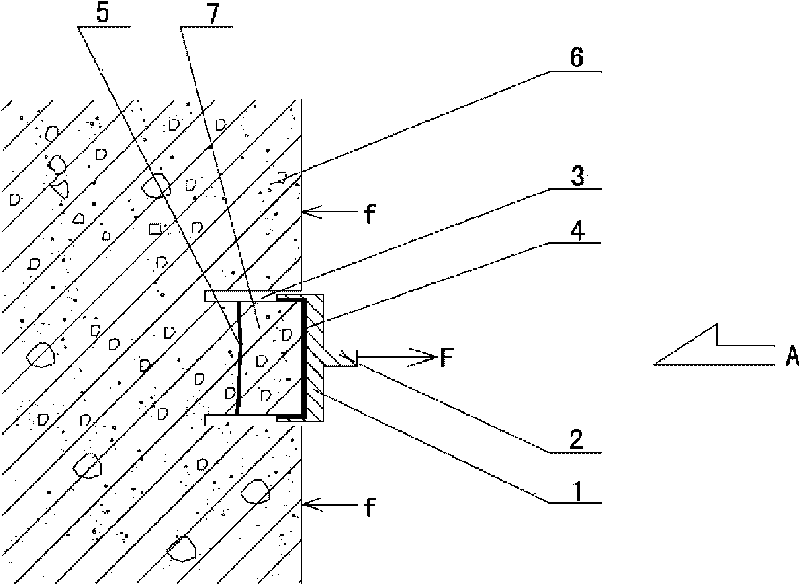

[0046] Examples see figure 1 , figure 2 Shown, the working process of the present invention is as follows:

[0047] 1. The standard part is a cylindrical steel straight-drawing standard part 1, and there is a connecting head 2 in the center of the outer bottom of the cylinder, and the connecting head is connected to the drawing instrument.

[0048] 2. The outer diameter of the steel straight drawing standard part 1 is 48mm, the inner diameter is 45mm, the cylinder height is 22mm, and the cylinder bottom thickness is 2mm.

[0049] 3. The diameter of the connector 2 of the steel straight pull standard part 1 is 15 mm, and the length of the connector is 15 mm.

[0050] 4. The drawing system is composed of a tension sensor, a hydraulic drawing instrument and a load gauge.

[0051] 5. The detection steps are as follows:

[0052] Step 1) Select a measured plane on the measured concrete matrix 6 .

[0053] Step 2) Use a hollow water drill with an inner diameter of not less than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com