Carbon paste electrode and preparation method thereof

A carbon paste electrode and carbon paste technology, applied in the field of electrochemical analysis, can solve the problems of troublesome, low efficiency, time-consuming and labor-intensive surface renewal of carbon paste electrodes, and achieve the effects of easy reuse, high efficiency and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

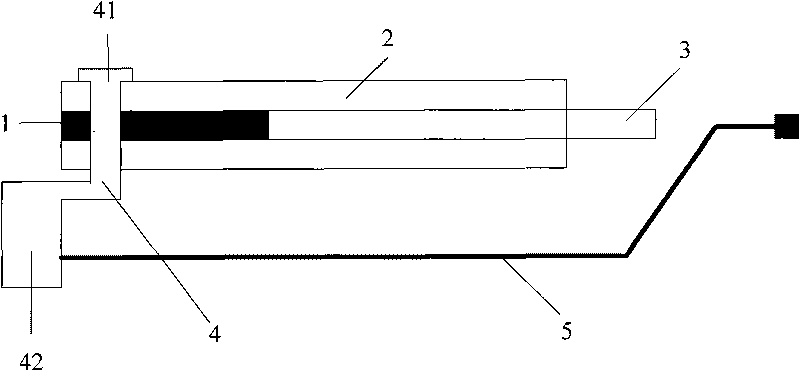

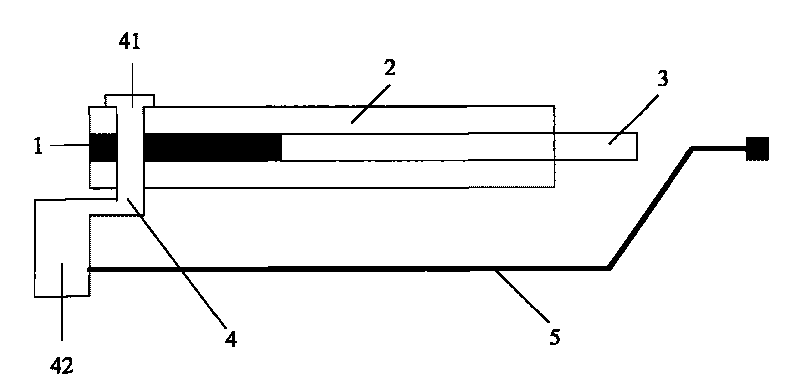

[0029] The present invention also provides a method for preparing a carbon paste electrode, comprising:

[0030] Fill the carbon paste inside the electrode shell;

[0031] Installing one end of the electrode lead wire inside the electrode shell and connecting it with the carbon paste, and leading the other end of the electrode lead wire out from the inside of the electrode shell;

[0032] The renewal brush is set on the outside of the electrode casing, and the renewal brush can rotate relative to the electrode casing;

[0033] A rotary driving device is installed on the updating brush, and the rotating driving device can drive the updating brush to rotate relatively around the electrode casing.

[0034] According to the present invention, with the electrode shell as the center, carbon paste is filled inside the electrode shell, electrode lead wires are drawn out from the electrode shell, a renewal brush is placed on the outside of the electrode shell, and the renewal brush is...

Embodiment 1

[0045] Take 55mg of carbon powder and 45mg of methyl silicone oil and grind them carefully in an agate mortar to obtain a uniform and stable carbon paste mixture; then use a small spoon to put the carbon paste mixture into a cleaned 4cm long, 1mm internal diameter, 1mm external diameter One end of the polytetrafluoroethylene electrode shell of 3 mm; the other end of the polytetrafluoroethylene shell is plugged with a copper rod with a length of 5 cm and a diameter of 1 mm as the electrode lead, and the part of the copper rod inserted into the electrode shell is 3 cm long; A renewal brush with a polytetrafluoroethylene sleeve and a sandpaper brush body is sheathed on the outside of the polytetrafluoroethylene casing, the brush body is connected to a rotating rod, and the rotating rod is connected to a motor. Turn on the motor, and the rotating rod drives the renewal brush to rotate around the electrode shell to polish the surface of the carbon paste electrode smooth.

[0046] P...

Embodiment 2

[0049] Take 65mg of carbon powder and 35mg of paraffin oil and grind them carefully in a mortar to obtain a uniform and stable carbon paste mixture; then use a small spoon to put the carbon paste mixture into a cleaned 7cm long, 3mm inner diameter, and 6mm outer diameter One end of the plastic electrode shell; the other end of the plastic shell is plugged with a stainless steel rod with a length of 7 cm and a diameter of 3 mm as the electrode lead, and the part of the stainless steel rod inserted into the electrode shell is 4 cm long; there will be a plastic sleeve and a sulfuric acid paper brush The updating brush of the body is covered on the outside of the plastic tube shell, the brush body is connected with the rotating rod, and the rotating rod is connected with the motor. Turn on the motor, and the rotating rod drives the renewal brush to rotate around the electrode shell to polish the surface of the carbon paste electrode smooth.

[0050] Place the carbon paste electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com