Seamless-molding preparation method of scatterer for sonic crystal

A technology of phononic crystals and scatterers, which is applied in the field of seamless molding and preparation of scatterers for phononic crystals, can solve the problems of scatterers that have not been reported, and achieve the effects of strong designability, stable performance, and uniform interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the preparation method of seamless molding of scatterers for phononic crystals according to the present invention, the scatterers prepared by molding are composed of a covering body and a vibrator, and the covering body is made of silicone rubber, which has soft material, large shear modulus, It has the characteristics of low density and simple molding.

[0031] The vibrator adopts metal particle balls, metal particle balls or steel balls, or tungsten balls, or copper balls, or lead balls, or aluminum balls. Metal particle balls have the characteristics of high rigidity and high density.

[0032] The seamless molding preparation of the cladding body and the vibrator is realized through the scatterer forming mold. The structure of the scatterer forming mold is as follows:

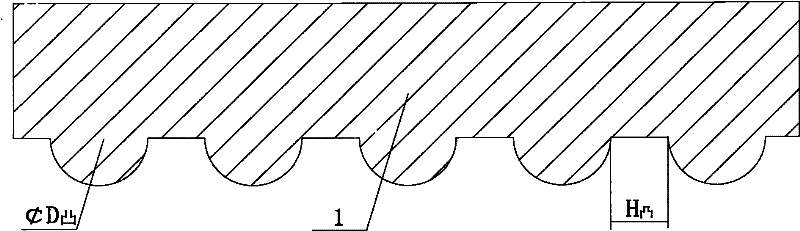

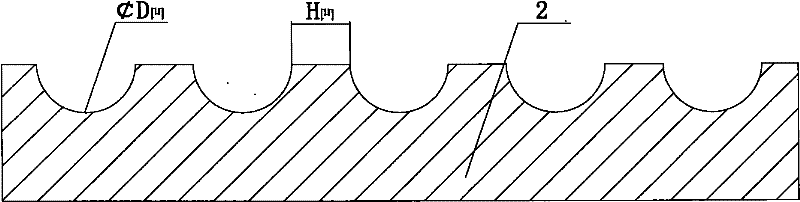

[0033] combine Figure 1-2 , The scatterer forming mold is divided into a concave forming plate 2 and a convex forming plate 1. The concave forming plate is generally rectangular, but the concav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap