Gas mixing module and breathing machine and anesthesia machine with same

A gas mixing and mixing cavity technology, applied in the field of medical devices, can solve the problems of reducing battery life, difficult to achieve precise control, difficult to achieve large flow, etc., to ensure stable operation, improve positioning repeatability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims. The same components are denoted by the same reference numerals in the drawings.

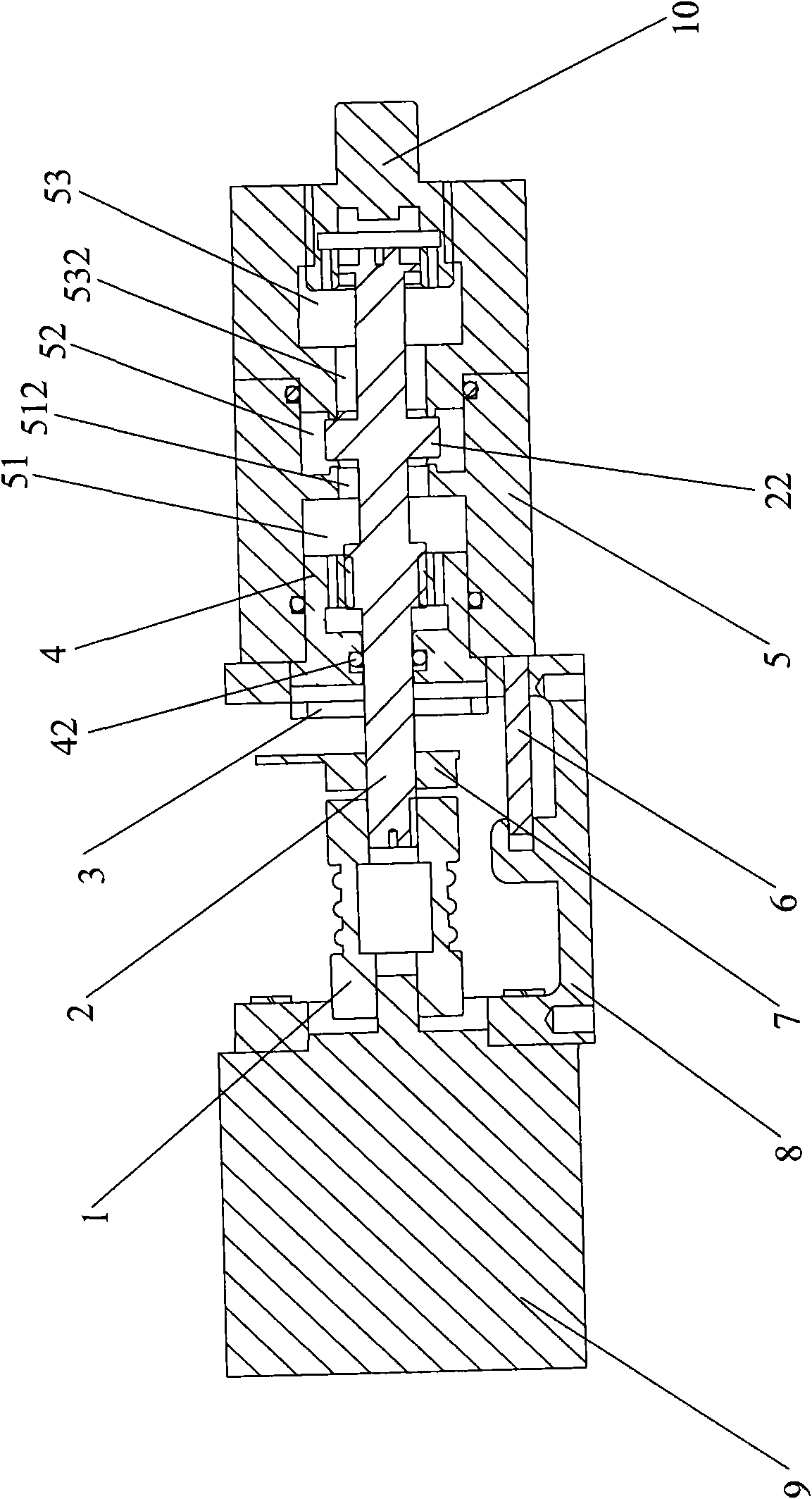

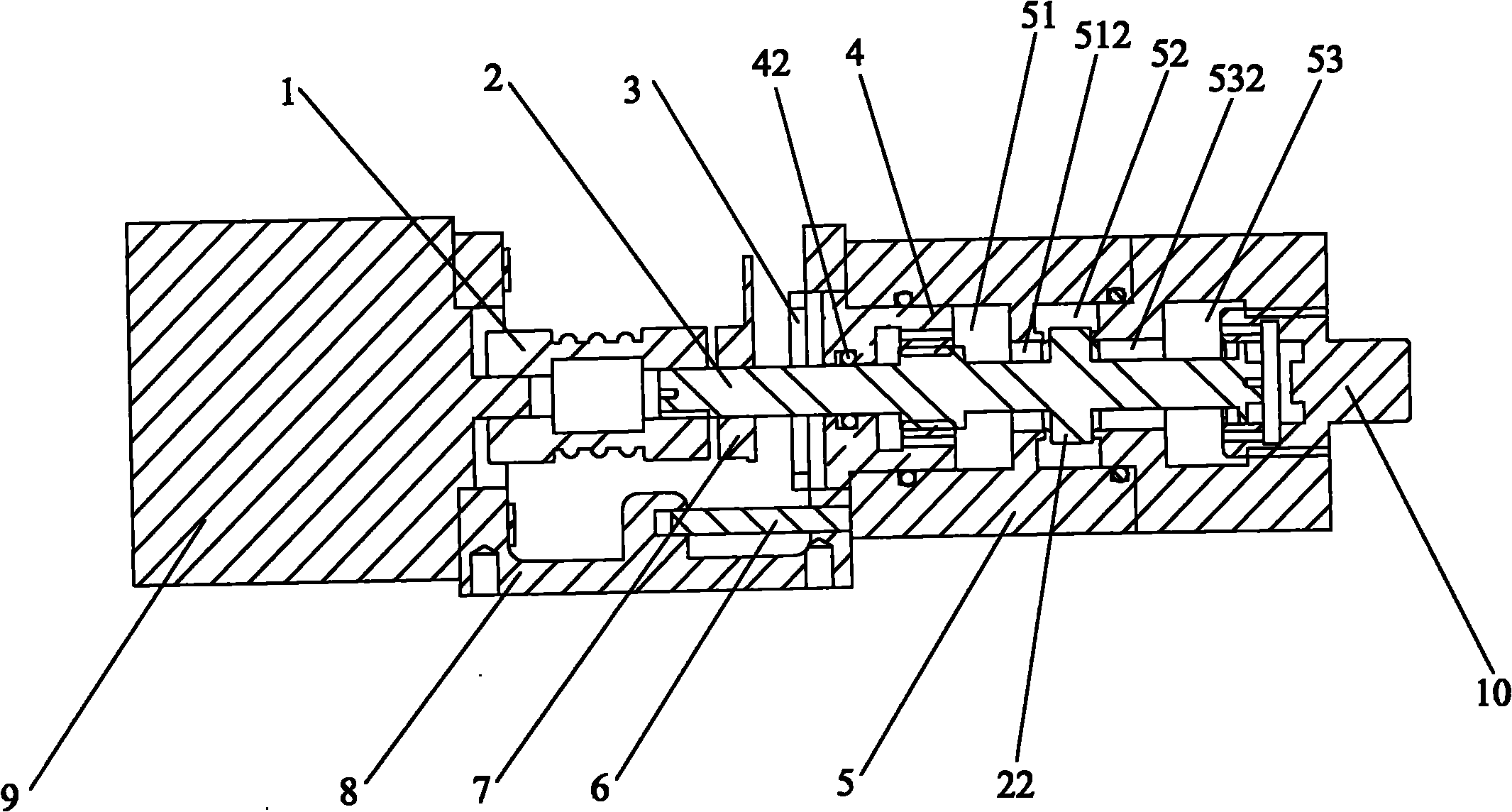

[0022] refer to figure 1 , the air-oxygen mixing module of the present invention includes: a housing 5, a mandrel 2 and a stepping motor 9 for driving the mandrel 2, wherein a mixing chamber 52 and air on both sides of the mixing chamber are formed in the housing 5 The chamber 5 and the oxygen chamber 53, the air chamber 51 and the oxygen chamber 53 communicate with the mixing chamber 52 through the air outlet 512 and the oxygen outlet 532 respectively, so as to input air and pure oxygen into the mixing chamber respectively. In this example, if figure 1 As shown, the mandrel 2 passes through the air chamber 51, the mixing chamber 52 and the oxygen chamber 53 sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com