Rice hull biologic grain forming and rice milling machine

A particle forming machine and biological particle technology, applied in the direction of material forming presses, applications, presses, etc., can solve the problems of waste of manpower and material resources, and achieve the effects of reducing waste, simple structure, and time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

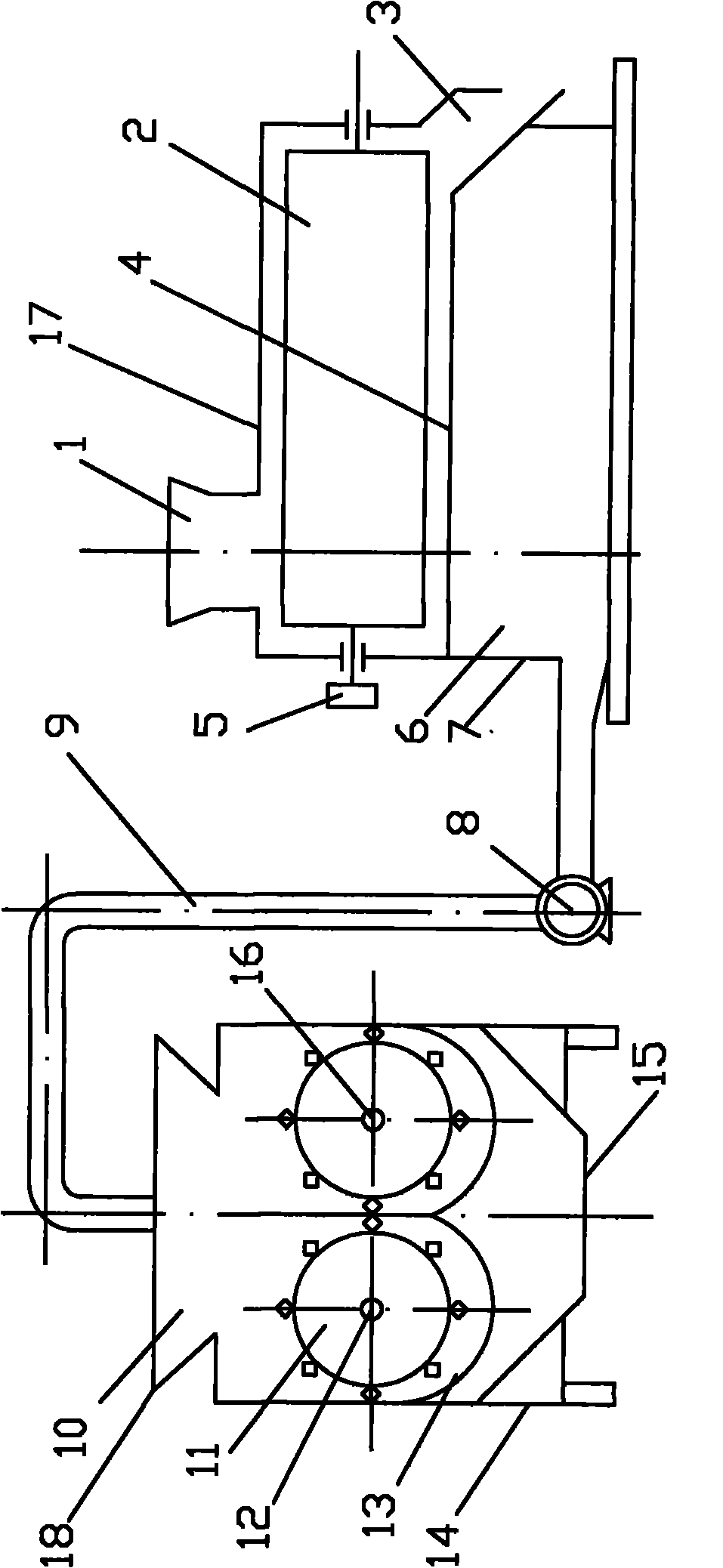

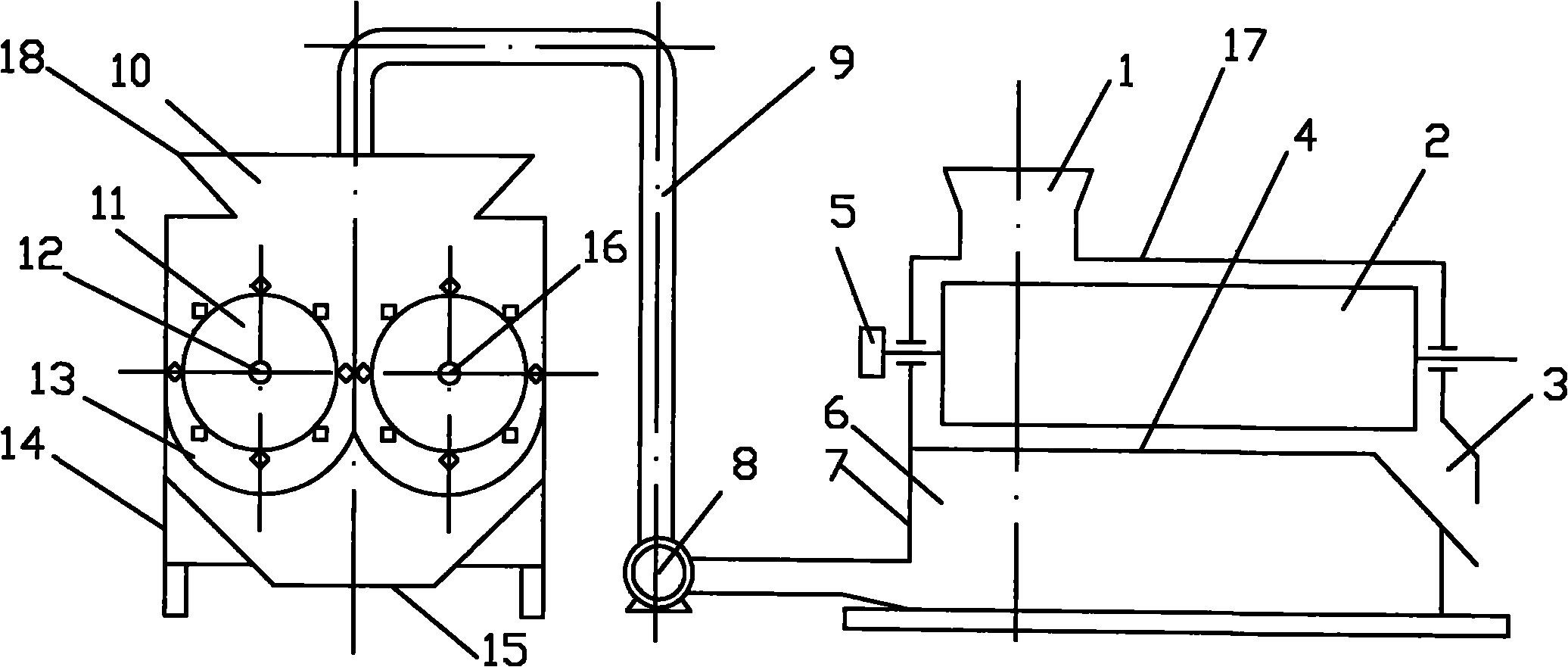

[0011] Such as figure 1 As shown, the present invention includes a rice mill 17, a particle molding machine 18, a delivery channel 9, and a fan 8, and the rice mill 17 includes a frame 7, and the grain inlets arranged in turn from top to bottom inside the frame 7 1. Rice milling room 2, the rice bran room 6, the rice milling device in the rice milling room 2 is movably connected with the transmission mechanism 5, and a rice sieve 4 is arranged between the rice milling room 2 and the rice bran room 6 , the lower side of the rice milling chamber 2 is provided with a rice outlet 3, the rice bran chamber 6 communicates with the conveying channel 9, the particle molding machine 18 includes a frame 14, and the inside of the frame 14 is viewed from above. The shell inlet 10, the particle forming chamber 19, and the discharge port 15 arranged in sequence below, the particle forming device in the particle forming chamber is connected with the driving device, and the shell inlet 10 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com