Combined type machine set integrating functions of banburying, feeding and extruding into whole

A combined single-screw extruder technology, applied in the field of machinery, can solve the problems of complex production process, waste of manpower, material space, and low work efficiency, and achieve the effects of simplifying the process flow, saving enterprise costs, and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

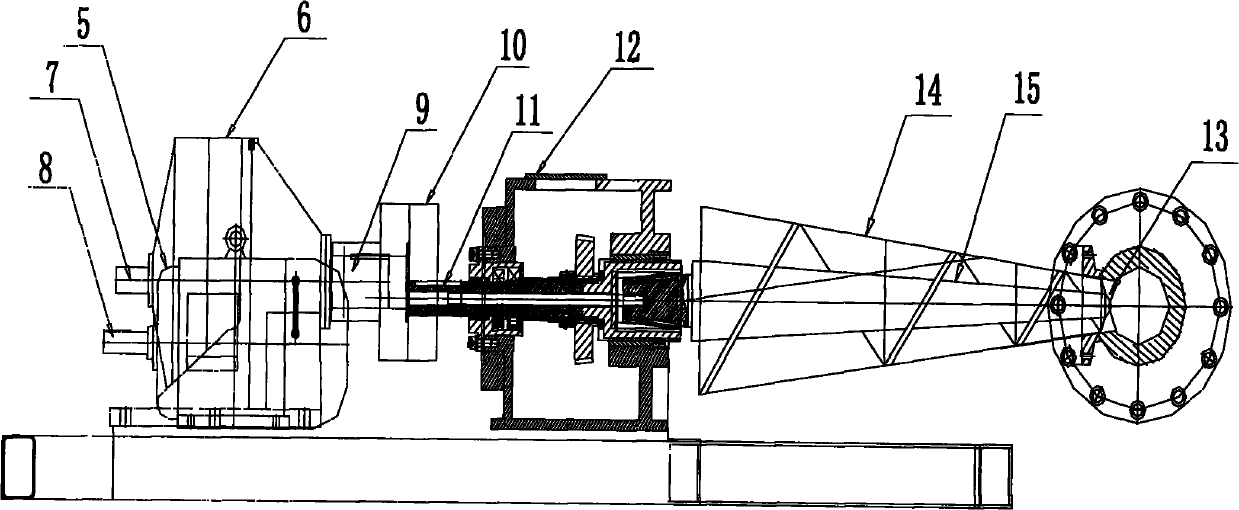

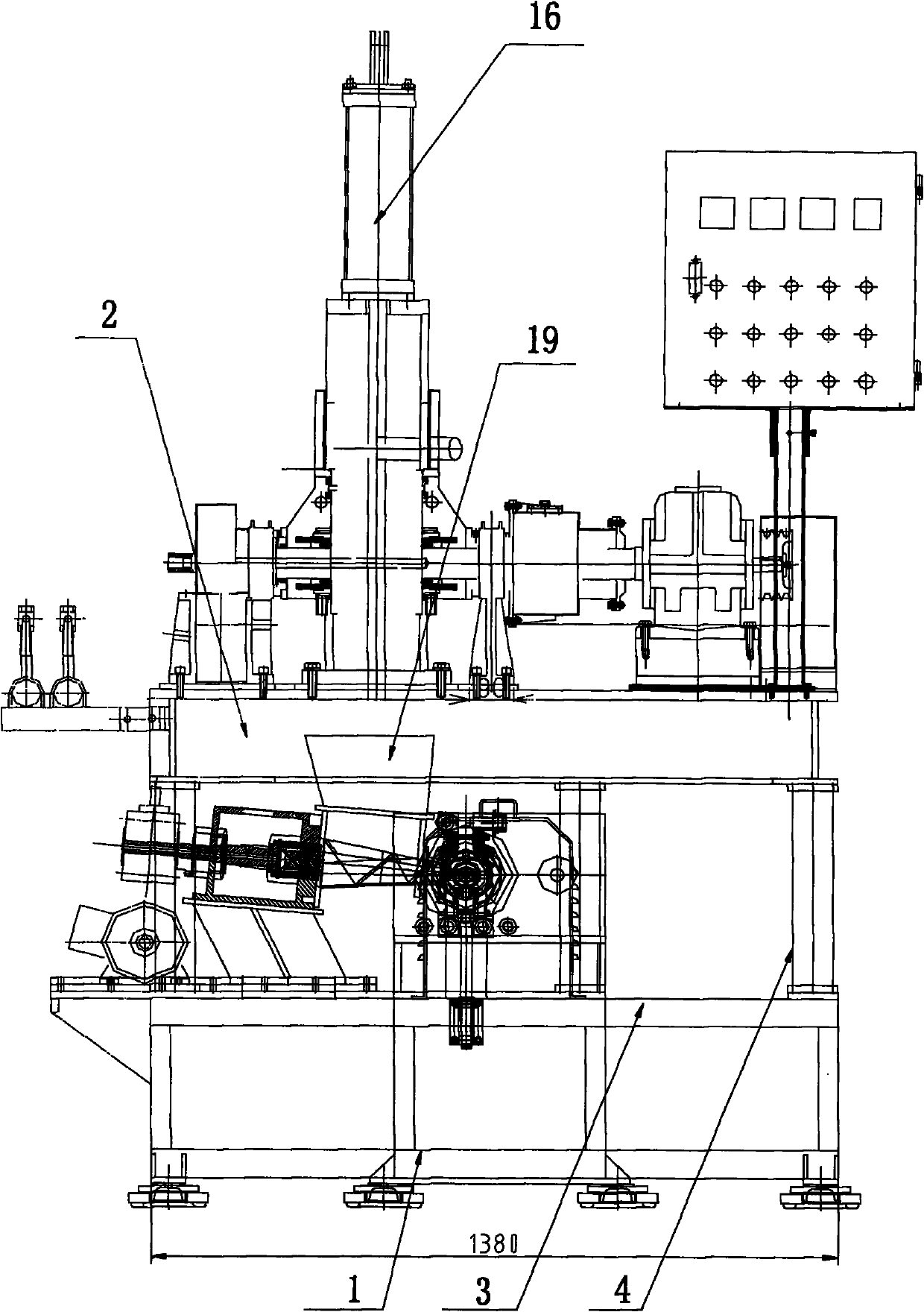

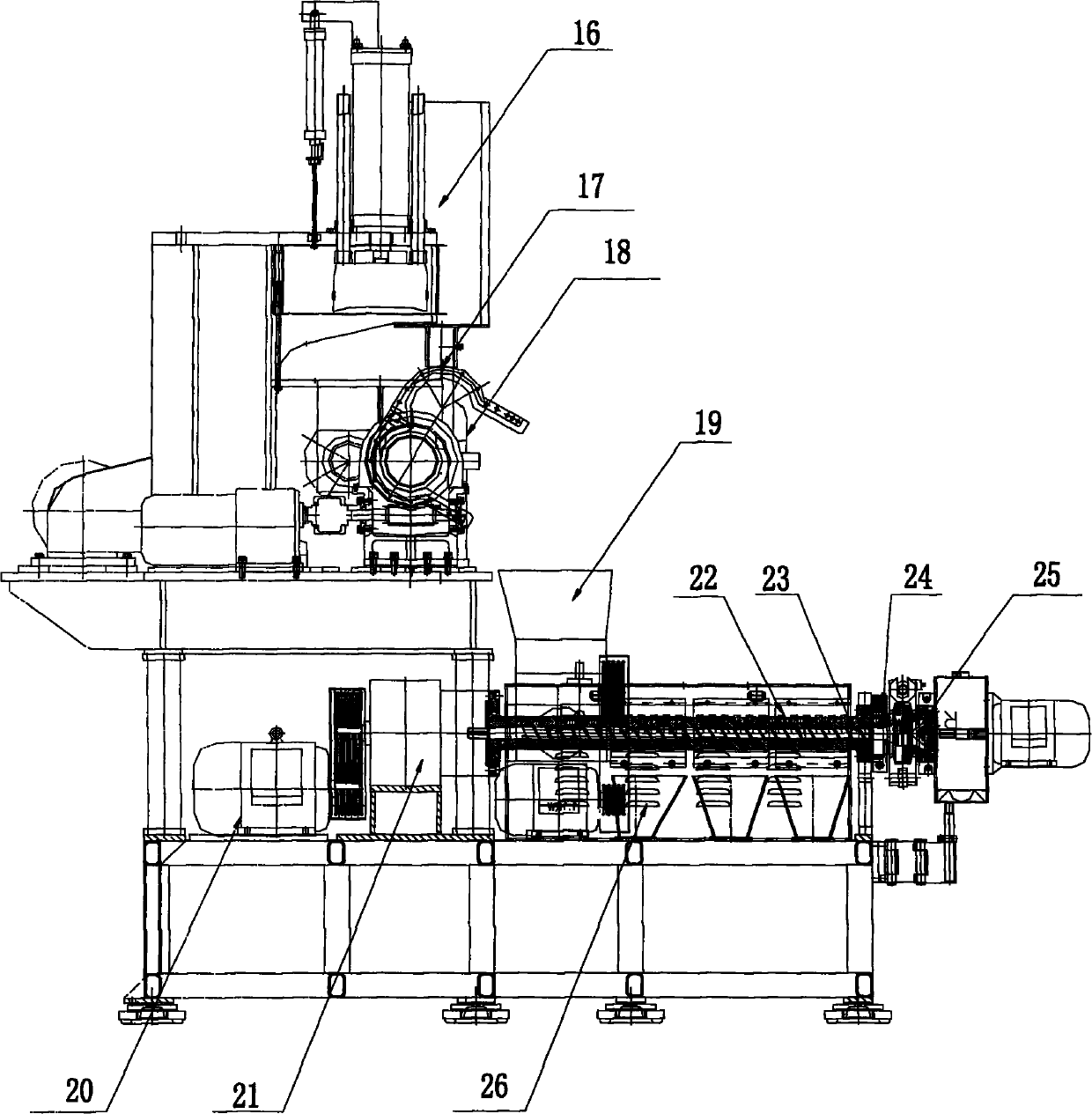

[0016] Such as figure 1 and 2 As shown, a combined unit integrating the functions of mixing, feeding, and extrusion includes a frame. The frame 1 is divided into two layers, namely the top layer 2 and the bottom layer 3. There are several support columns between the two layers. 4. On the bottom 3 of the frame 1, a conical twin-screw feeder is arranged, and its structure is as follows: figure 1 Shown, comprise AC motor 5, cycloid reducer 6, gear box 12, machine barrel 14 and conical twin-screw 15, described conical twin-screw 15 is arranged in the machine barrel 14, consists of main conical screw and Composed of secondary conical screws, an AC motor 5 is installed above the bottom 3 of the frame 1, the output end 8 of the AC motor 5 is connected to the input end 7 of the cycloidal pinwheel reducer 6, and the cycloidal pinwheel reducer 6 The output shaft 9 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com