Method for extracting high-purity aluminum oxide and silica gel from beauxite

A technology of bauxite and alumina, applied in the direction of silicon oxide, silicon dioxide, chemical instruments and methods, etc., can solve the problems of waste of resources, environment, pollution, etc., and achieve the goal of simplifying the process, reducing production costs, and reducing taste requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

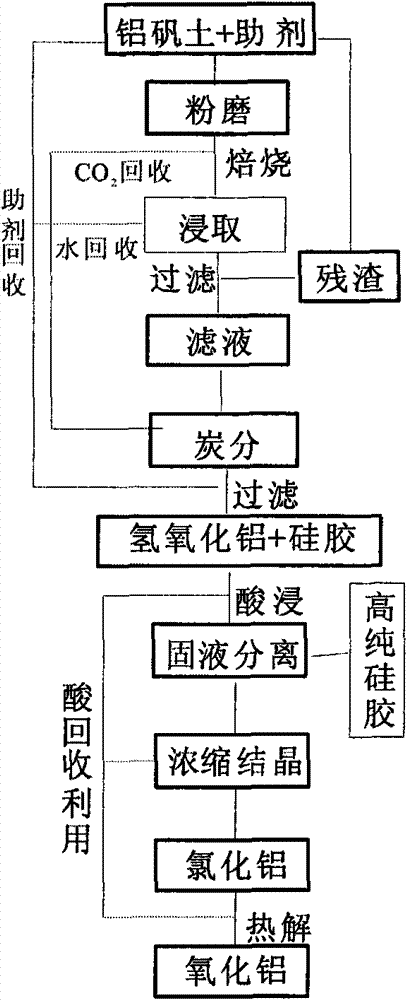

[0051] 1. Take bauxite and Na 2 CO 3 Mix, pulverize and grind to 150 mesh according to the ratio of 1:1.2, and roast at a temperature of 700° C. for 20 minutes to obtain a roasted product. During calcination, the calcination equipment is connected to the gas output pipe and connected to the carbon separation tank, and the exhaust gas is directly used in the carbon separation process.

[0052] 2. Add water to the roasted product obtained in step 1, make the solid-to-liquid ratio of the roasted product and water 1:5, leach for 30 minutes at a temperature of 80° C., and then filter to obtain filtrate and filter residue.

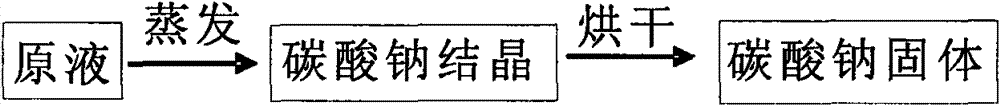

[0053] 3. After concentrating the filtrate obtained in step 2 to 20% of the volume of the original solution, pass CO 2 Carry out carbonation. During the process of carbonization, keep the solution temperature at 60°C, filter the carbon after the pH value reaches 6, and the filter residue is H 2 SiO 3 and Al(OH) 3 mixture, the filtrate is Na 2 CO 3 soluti...

Embodiment 2

[0061] 1, step 2 gained filter residue and the Na of reclaiming among the embodiment 1 2 CO 3 Mix according to the ratio of 1:0.8, grind to 200 mesh, stir evenly, and roast at 800°C for 20 minutes to obtain a roasted product. When roasting, the calcination equipment is connected to the gas output pipe and connected to the carbon separation tank, which is directly used in the carbon separation process.

[0062] 2. The roasted product obtained in step 1 is added with a concentration of 5% sodium hydroxide solution (obtained by dissolving and diluting sodium hydroxide with distilled water obtained in step 4 of Example 1), and the solid-liquid ratio is 1: 10, and the temperature is 50°C Under the conditions, leaching for 90 minutes and then filtering to obtain the filtrate and filter residue.

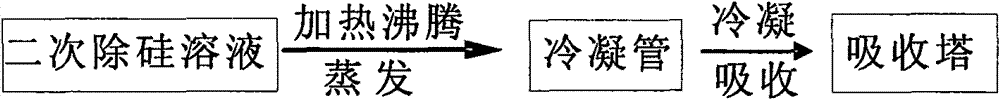

[0063] 3. Concentrate the filtrate obtained in step 2 to 15% of the original volume, and feed CO into the concentrated filtrate 2 , after the pH value reaches 6, filter, and the filter r...

Embodiment 3

[0071] 1, with the obtained filter residue of step 2 of bauxite, embodiment 2 and the Na reclaimed in embodiment 2 2 CO 3 , followed by mixing, pulverizing, and grinding to 200 meshes according to the ratio of 2:1:2, and roasting at a temperature of 800° C. for 40 minutes to obtain a roasted product. During calcination, the calcination equipment is connected to the gas output pipe and connected to the carbon separation tank, which is directly used in the carbon separation process.

[0072] 2. The roasted product obtained in step 1 is added with a concentration of 15% sodium hydroxide solution (obtained by dissolving and diluting sodium hydroxide with distilled water obtained in step 4 of embodiment 2), and the solid-to-liquid ratio is 1: 15, and the temperature is 60° C. conditions, leaching for 1 hour and then filtering to obtain the filtrate and filter residue.

[0073] 3. Concentrate the filtrate obtained in step 2 to 15% of the original volume, and feed CO into the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com