Novel double-chamber furnace for aluminum and aluminium alloy casting

An aluminum alloy, double-chamber furnace technology, applied in the field of smelting furnaces, can solve the problems of high raw material taste requirements, material waste smelting, single function, etc., to reduce the use cost and maintenance cost, reduce the increase of Fe elements, and reduce the skills of workers. The effect of request reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

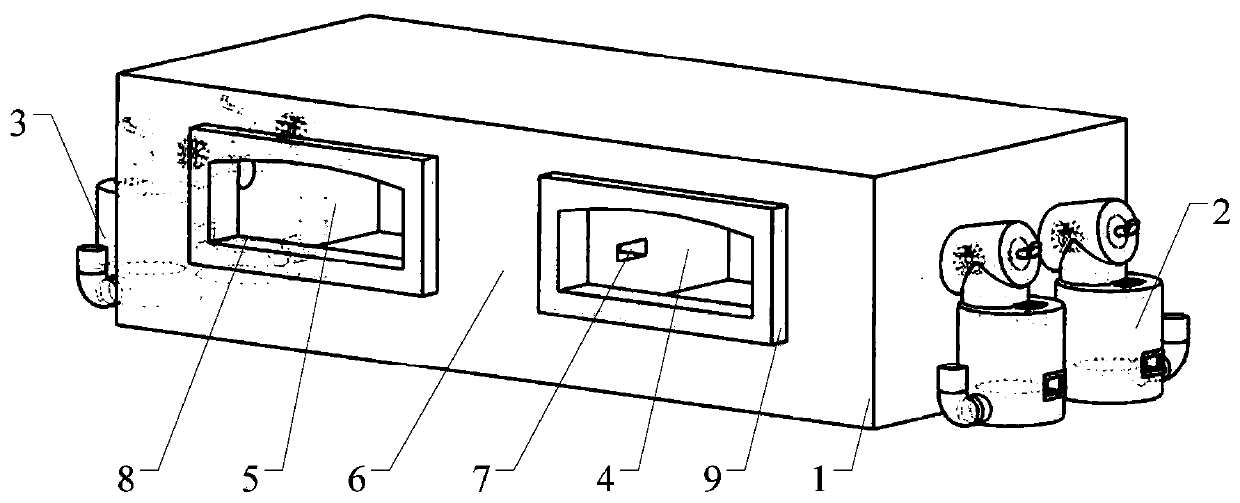

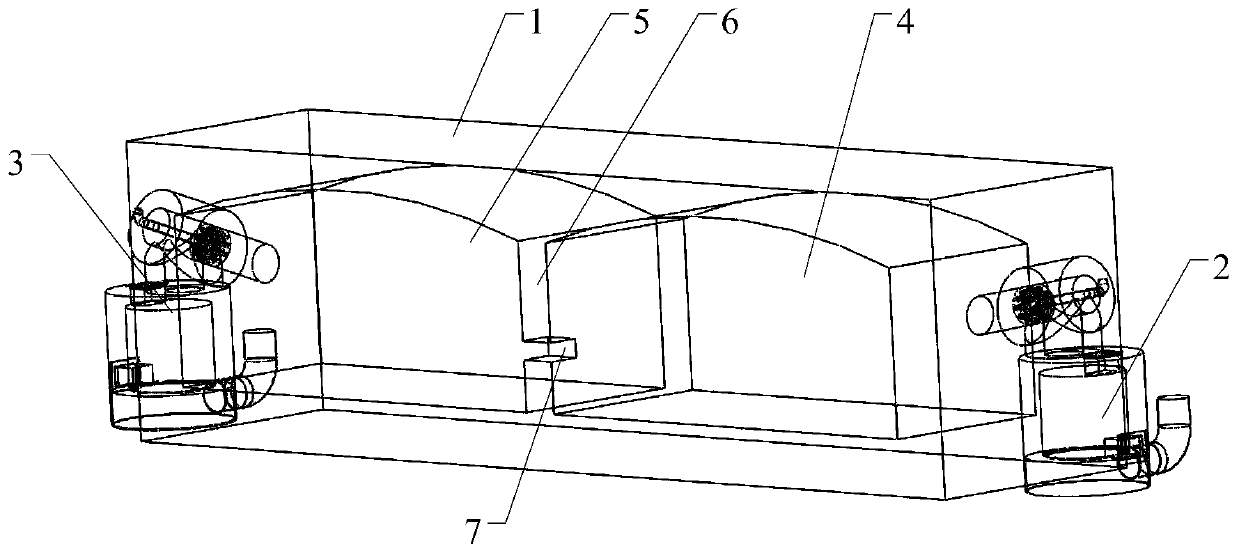

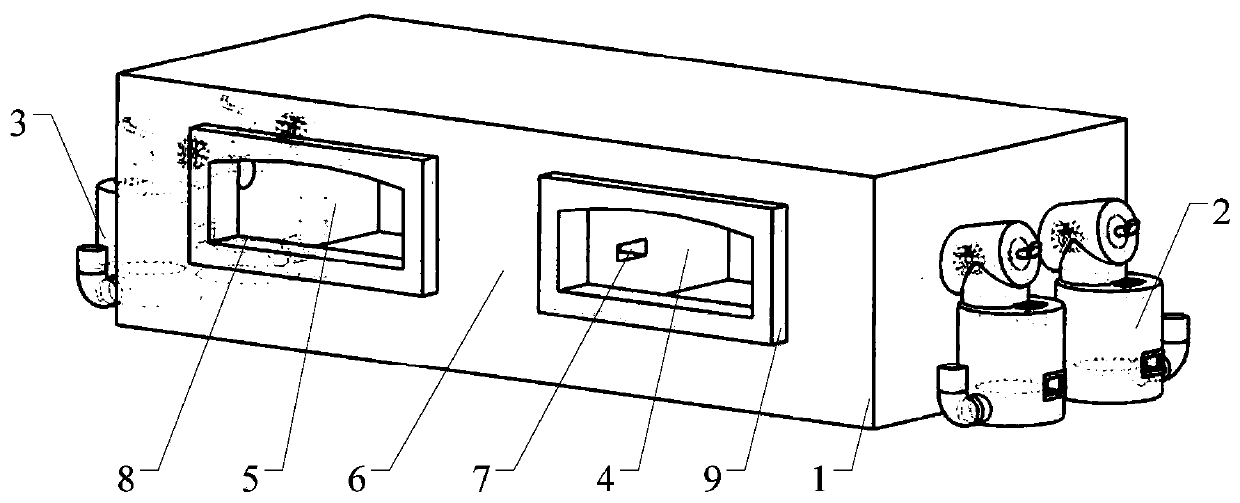

[0016] figure 1 It is a structural schematic diagram of an embodiment of a novel double-chamber furnace for melting and casting aluminum and aluminum alloys of the present invention, figure 2 It is a cross-sectional view of an embodiment of a novel double-chamber furnace for melting and casting aluminum and aluminum alloys of the present invention. As shown in the figure, the present invention provides a new double-chamber furnace for melting and casting aluminum and aluminum alloys, including a furnace body 1, a first The burner 2 and the second burner 3, the second burner 3 and the first burner 2 are respectively arranged on both sides of the furnace body 1; the furnace body 1 is provided with a first chamber 4 and a second chamber 5, the second chamber The second chamber 5 and the first chamber 4 are connected by a common furnace wall 6, and the common furnace wall 6 is provided with an aluminum liquid circulation channel 7, and one end of the aluminum liquid circulation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com