A noise reduction bridge expansion joint device with vertical displacement function

A technology for expansion joints and bridges, applied in the field of bridge expansion joints, can solve the problems of complex structure, easy entry of impurities and dirt into the shaft seat, and adverse effects of the rotation of the shaft seat of the rotating shaft, and achieve the effect of simple overall structure and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

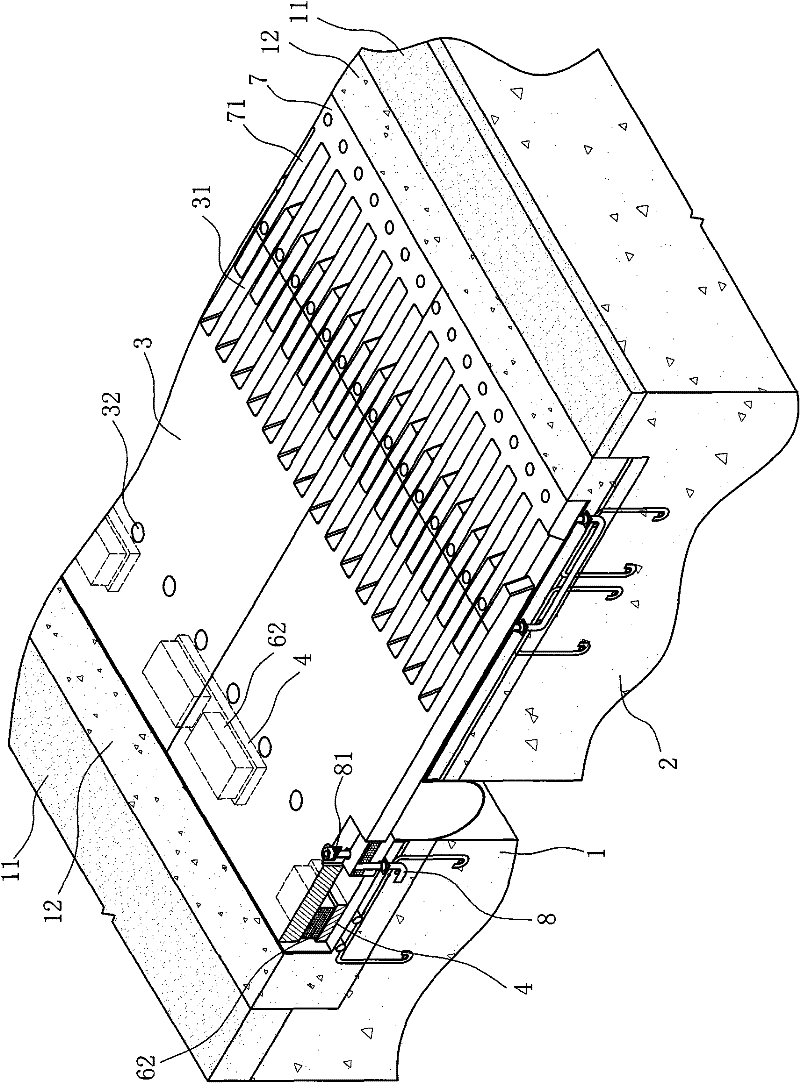

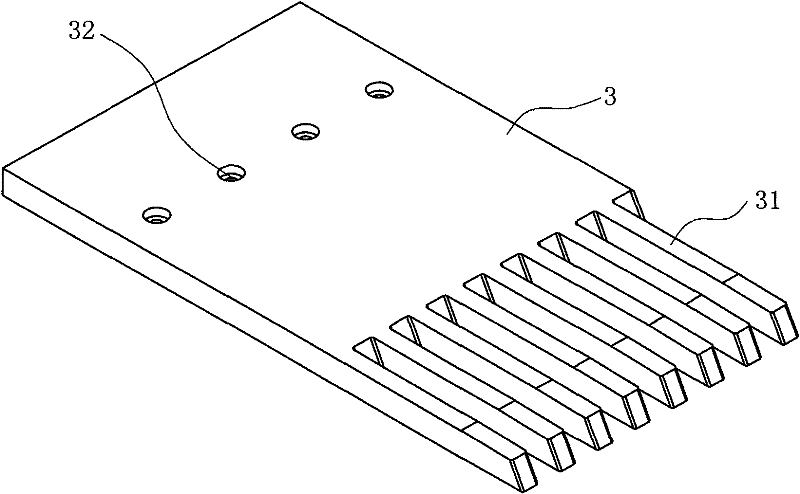

[0021] Such as Figure 1 ~ Figure 3 As shown, the noise-reducing bridge expansion joint device with vertical displacement function includes a first beam body 1 and a second beam body 2 located on both sides of the bridge expansion joint, and a movable comb arranged on the first beam body 1 Plate 3 and fixed comb plate 7 arranged on the second beam body 2;

[0022] Wherein, the movable comb plate 3 is a seam-spanning plate, the first end of the movable comb plate 3 is positioned on the first beam body 1 through the J-shaped fixing bolt 8, and the second end is positioned on the second beam body 2 and can be Move relative to the second beam body 2, the second end of the movable comb plate 3 is provided with comb teeth 31 and intersects with each comb tooth 71 of the fixed comb plate 7, and the end of each comb plate is connected to the corresponding beam body. A concrete layer 12 is poured between the road surfaces 11;

[0023] Between the bottom of the first end of the movabl...

Embodiment 2

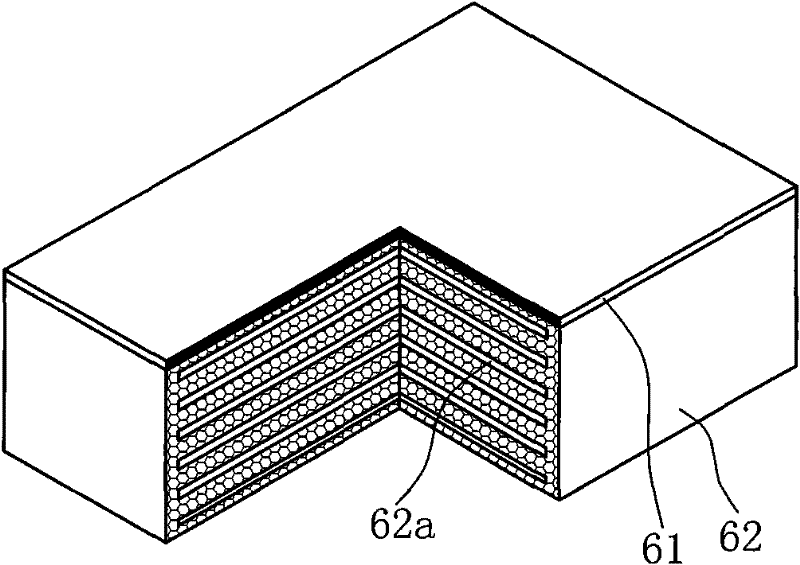

[0028] Such as Figure 4 ~ Figure 6 As shown, it is Embodiment 2 of the present invention, and what is different from Embodiment 1 is that a downwardly protruding positioning column 34 is provided at the bottom of the first end of the movable comb plate 3 (ie, the cross-slit plate), and the movable comb plate A hollow positioning box 5 fixed to the first beam body 1 is arranged under the first end of 3, and a positioning hole 51a is opened on the top plate 51 of the positioning box 5, and the end of the positioning column 34 passes through the positioning box 5. The positioning hole 51a extends into the positioning box 5 inside;

[0029] In this embodiment, a unit movable comb 3 is arranged with a group of plane slides 61, elastic liners 62 and support plates 4 and two sets of positioning columns 34, plane slides 61, elastic liners 62 and positioning boxes in its width direction. 5, see Figure 4 Shown in dotted line; Wherein, the thickness of support plate 4 is consistent w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com