Matched prefabricated concrete hollow slab beam structure

A prefabricated concrete and hollow slab beam technology, applied in structural elements, truss structures, bridges, etc., can solve problems such as failure to prevent and control longitudinal cracks in the bottom plate, and achieve the effect of enhancing the overall effect, avoiding longitudinal cracks, and preventing rainwater immersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

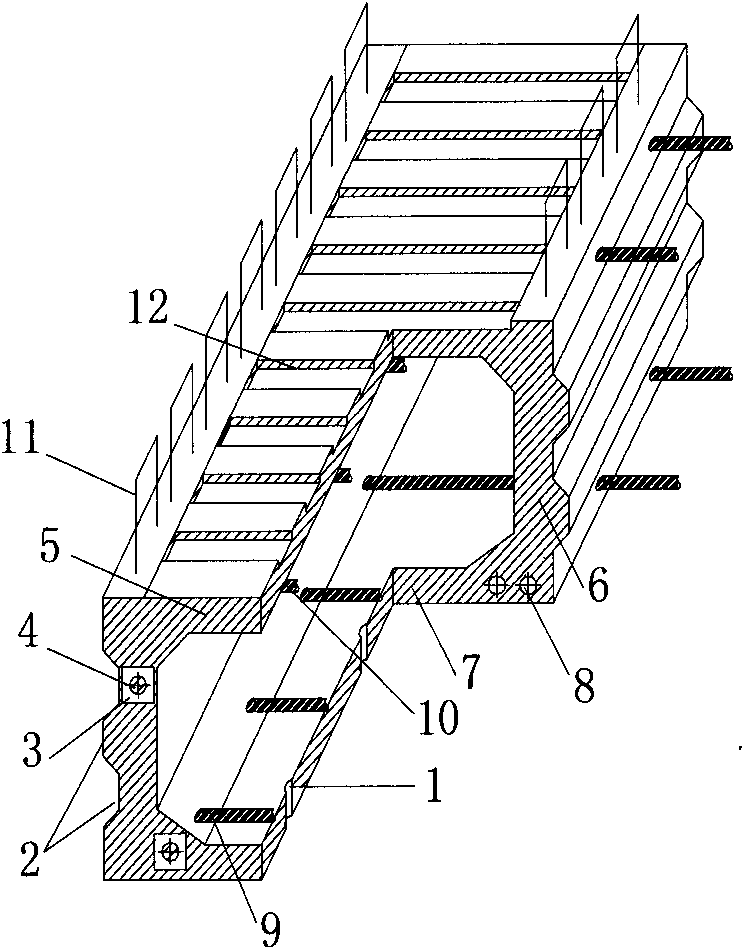

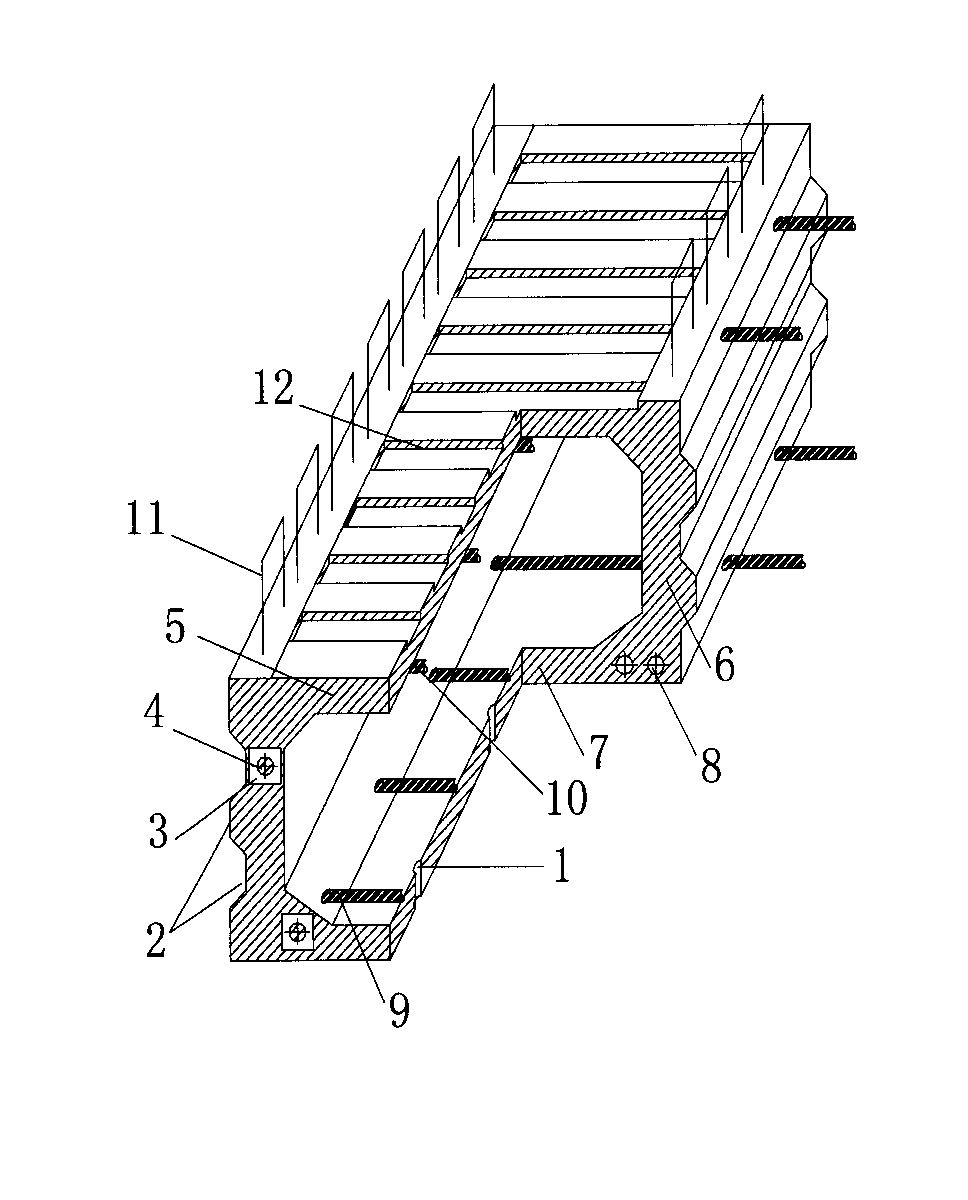

[0025] The accompanying drawings disclose non-restrictive structural schematic diagrams of specific embodiments involved in the present invention, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The matching prefabricated concrete hollow slab girder structure of the present invention includes a top plate 5, a web 6 and a bottom plate 7 surrounding a plate girder structure, a hollow cavity is arranged in the plate girder structure, and the top plate 5, web 6 and bottom plate 7 is formed by pouring concrete, and the outer surface of the web 6 is arranged with a shear key 2 in a prefabricated manner. Therefore, the present invention adopts the shear key 2 instead of the traditional hinge joint design, that is, in the prestressed concrete hollow slab described in the present invention During the beam prefabrication process, the cast hollow slab girder structure is used as the side form of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com