Double-rotor rolling-piston-type expansion engine for cold water machine set

A rolling piston type, chiller technology, used in machines/engines, refrigerators, refrigeration components, etc., can solve problems such as difficulty in developing high-efficiency expanders, large expansion, and loss of expansion work.

Inactive Publication Date: 2010-07-07

TIANJIN UNIV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For the reverse Carnot cycle, it is easy to achieve theoretically by reducing the pressure and recovering the expansion work through the expander, but in the actual vapor compression refrigeration cycle, the expansion process is relatively large, and the phase change expansion process itself is very complicated, and the high-efficiency ex

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

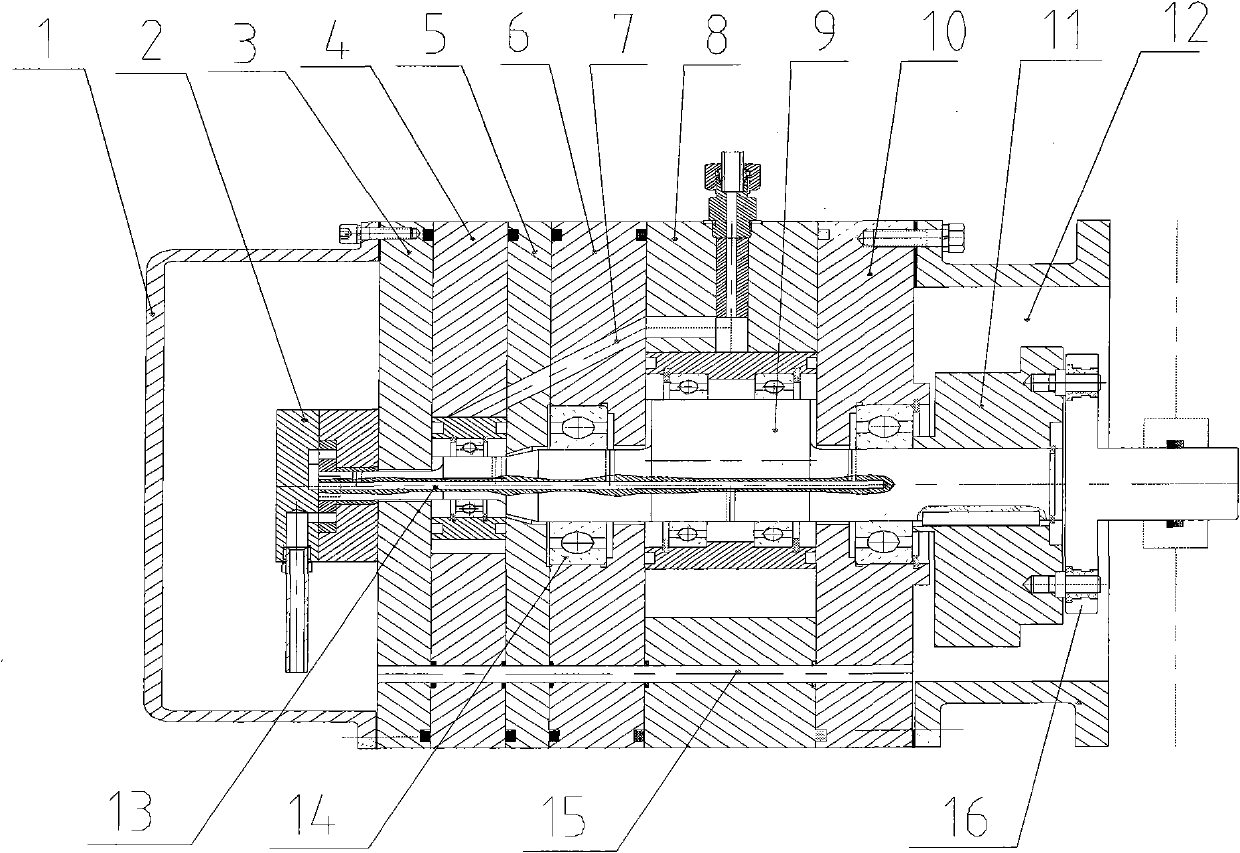

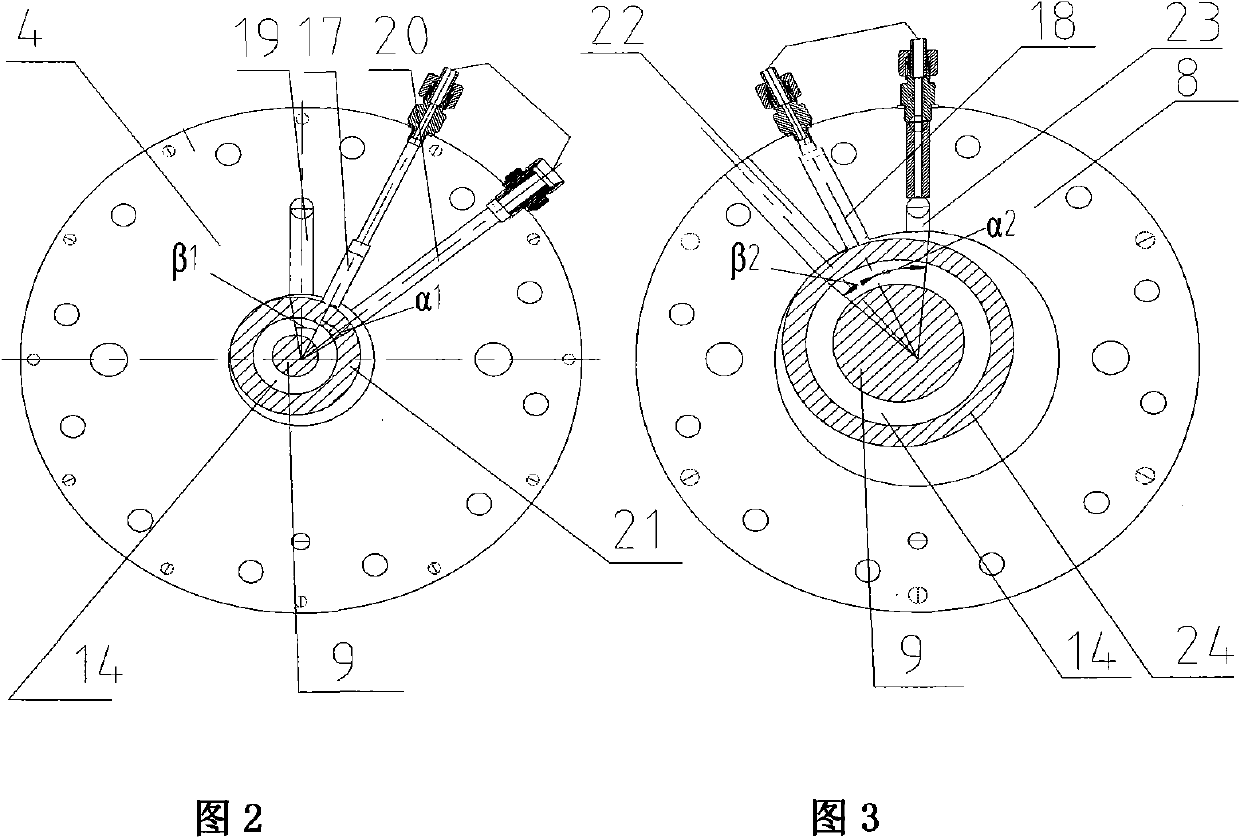

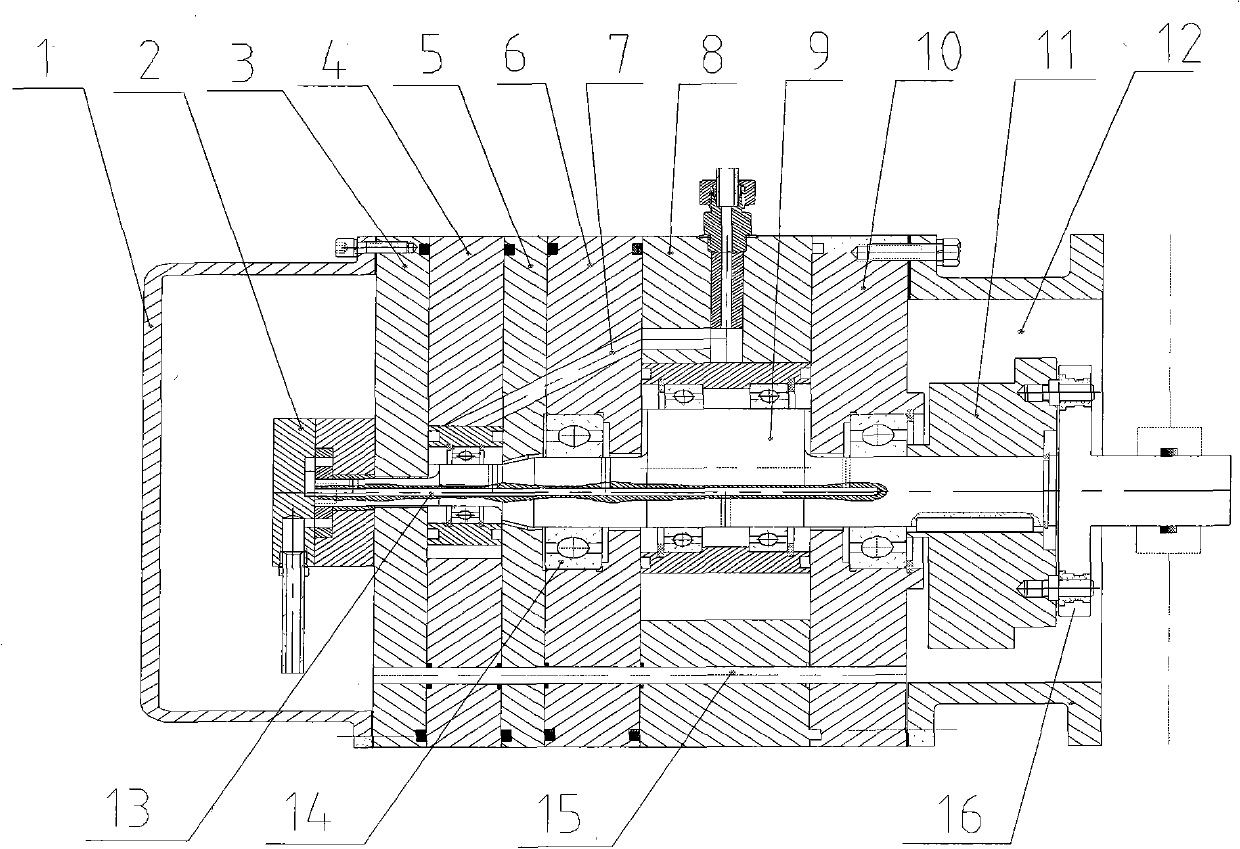

The invention discloses a double-rotor rolling-piston-type expansion engine for a cold water machine set. The expansion engine has a horizontal-type structure and is formed by connecting two cylinders in series; front and rear end covers of cylinder bodies, the cylinder bodies, a two-cylinder gas connecting channel, an oil return chamber and other parts which are sequentially sealed and connected by bolts; cranks are embedded into bearings of the front and the rear end covers of the second cylinder body; a lubricating oil pump is arranged at the outer side of the front end cover of the first cylinder body, and an outlet of the oil pump is connected with an oil supply channel; return oil returns a lubricating oil chamber from the oil return chamber through an oil return channel; the outer end of a crankshaft is nested with a balance weight; and the crankshaft and a flange connected with a motor have the same axle center. The double-rotor rolling-piston-type expansion engine omits a suction control device of a single-stage rolling-piston-type expansion engine, directly utilizes a first cylinder to control suction capacity, adjusts the inner diameter size dimension of two cylinders so as to meet different expansion ratio, and realizes the design with high expansion ratio. By adopting the expansion engine to replace a throttle valve, the expansion work can be easily recovered, the refrigerating output is obviously increased by the cold water machine set, and the performance is stable and reliable.

Description

technical field [0001] The invention belongs to refrigeration machinery, in particular to a rolling piston expander in a chiller system. Background technique [0002] With the rapid growth of the gross national product and the continuous improvement of people's living standards, people's pursuit of quality of life has gradually improved, which has led to the rapid development of chillers in our country. In 2004, my country formulated the "Energy Efficiency Limits and Energy Efficiency Levels of Chillers", which stipulates five levels of energy efficiency levels, of which level 5 is the lowest entry level, and level 2 and level 1 are energy-saving levels. At present, most of the chillers are equivalent to the 3rd and 4th grades of the national energy efficiency standard, and some still barely reach the 5th grade. In recent years, people have mostly done a lot of work on the design of the cycle principle, high-efficiency compressor (screw type, centrifugal type), throttling m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F01C11/00F01C21/04F25B41/00

Inventor 田华马一太李敏霞张云宪董克勤

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com