Solar collector installed with horizontally inserted, densely arranged and jacking evacuated solar collector tubes with location tube joints

A vacuum heat collection tube, installation and positioning technology, which is applied in the field of vacuum heat collection tube solar collectors, can solve the problems of high price, high production cost, and reduced service life of the whole machine, and achieve the effect of reasonable price, firm fixation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

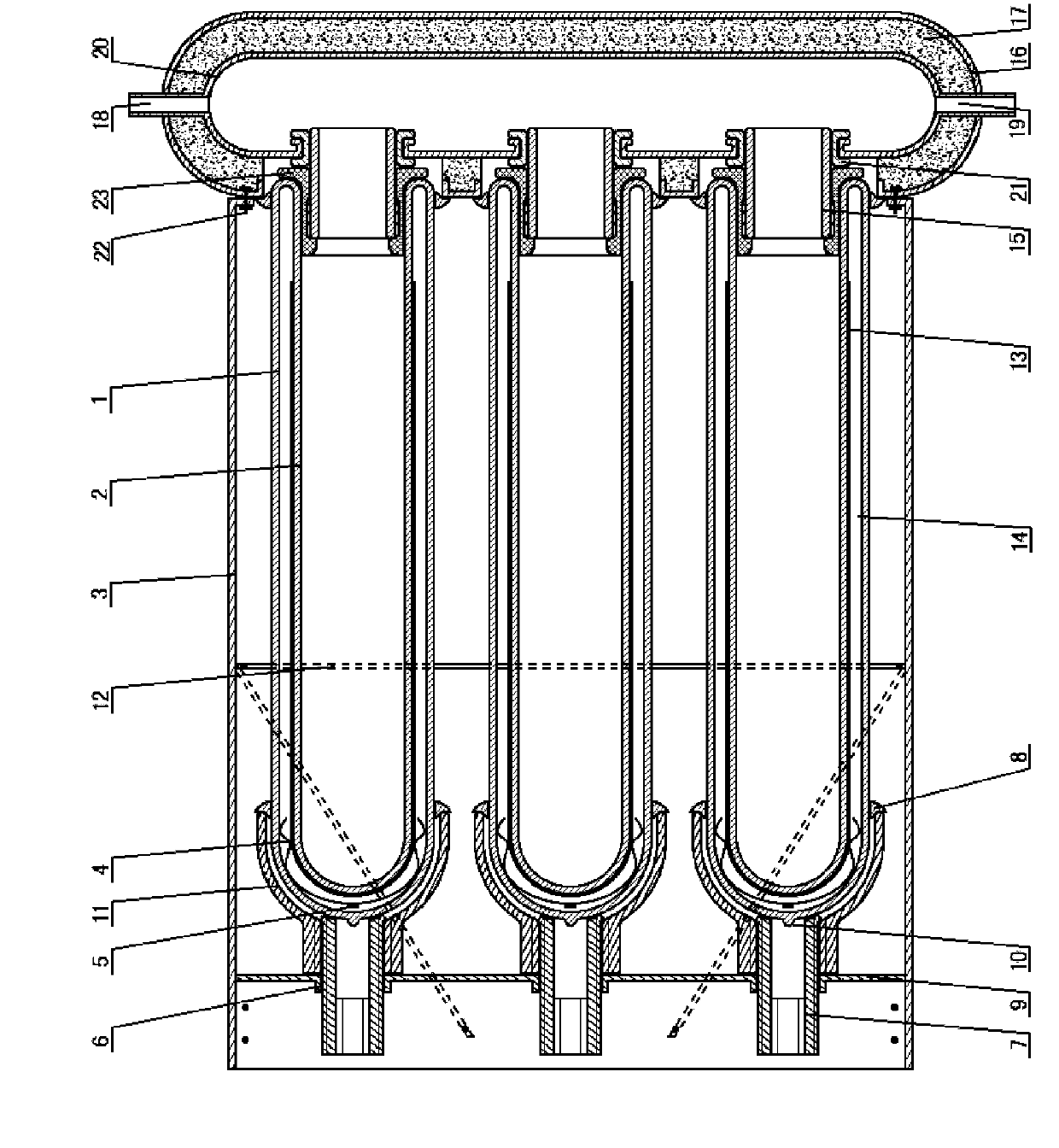

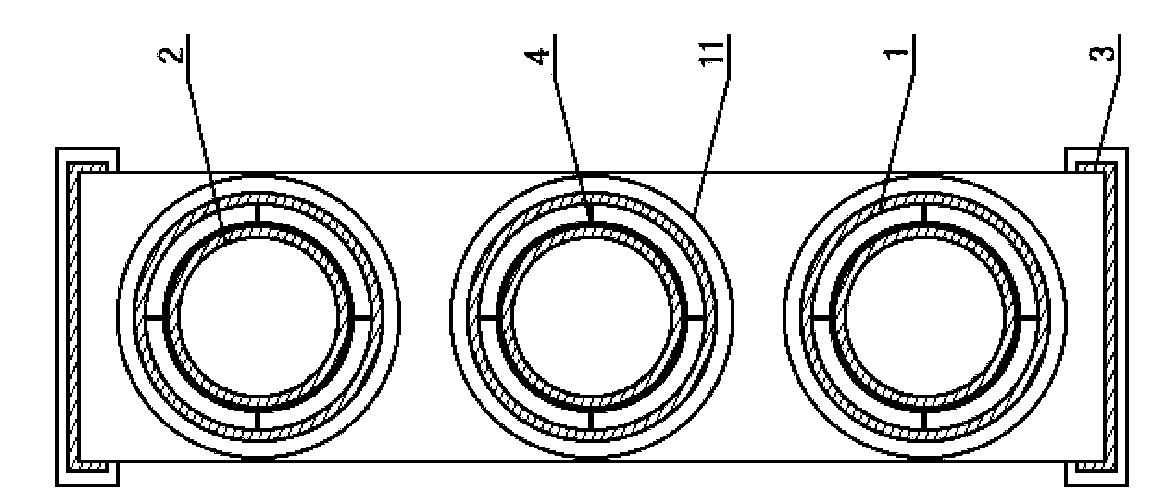

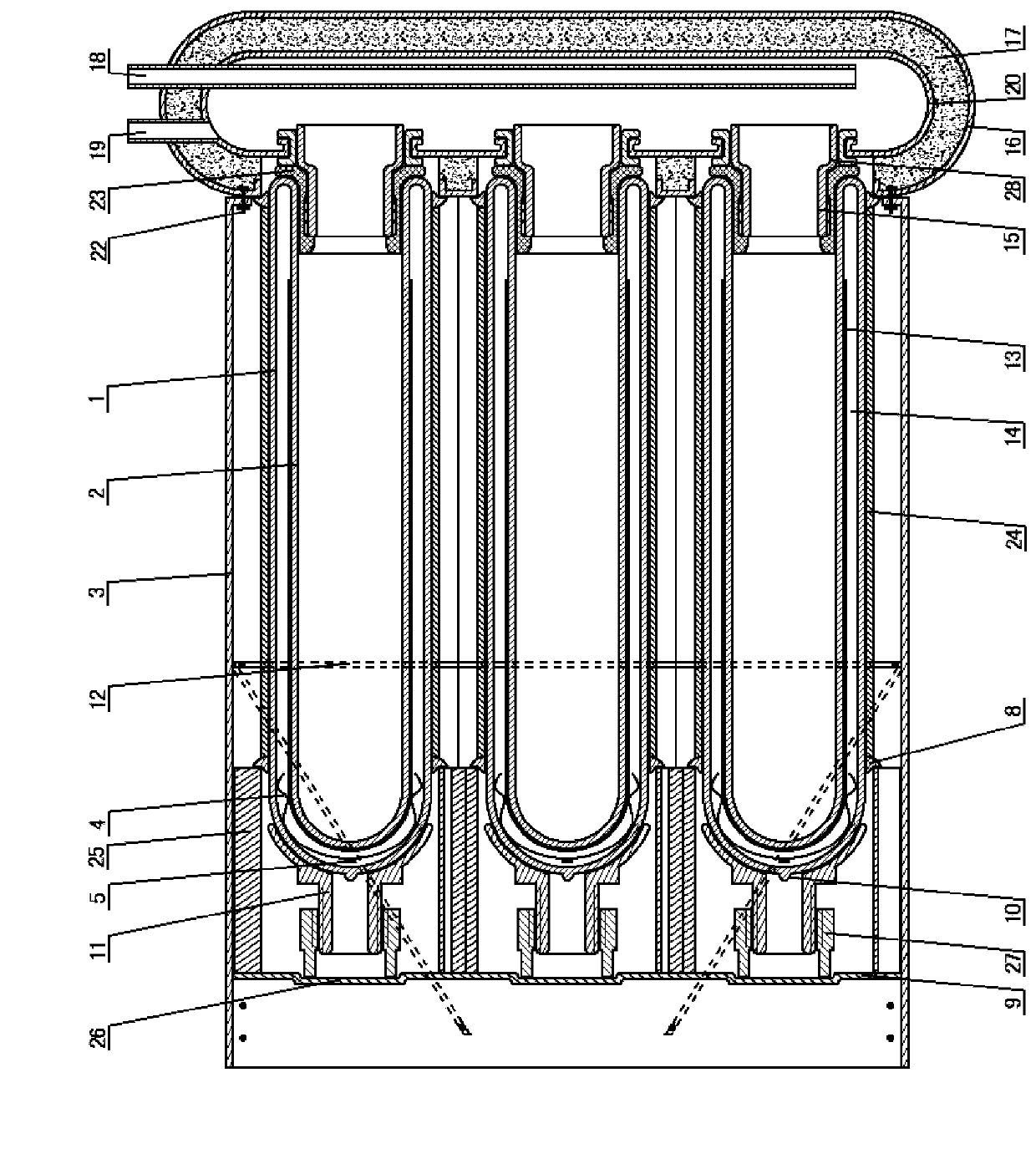

[0034] Such as figure 1 , figure 2 Shown: a solar collector with vacuum heat collecting tubes inserted horizontally and densely arranged on the top and tightly installed with positioning tube heads, including a water tank outer barrel 16, a water tank insulation layer 17, a water tank liner 19, a vacuum heat collecting tube, a fixed bracket 3, and a vacuum collector The heat pipe tailstock, the water tank liner 19 is placed in the water tank outer barrel 16, the water tank insulation layer 17 is established between the water tank liner 19 and the water tank outer barrel 16, and the water tank liner 19 is provided with a water inlet 18 and a water outlet 20. The water tank is vertically installed on one end of the fixed support 3, and the same side of the water tank outer barrel 16, the water tank insulation layer 17, and the water tank liner 19 have coaxial holes for inserting vacuum heat collecting tubes, and the vacuum heat collecting tubes are inserted into the mouth of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com