Method for testing control board of electromagnetic valve

A test method and solenoid valve technology, applied in the testing of machine/structural components, measuring devices, instruments, etc., can solve the problems of complex operation, inaccuracy, easy damage to switches, etc., and achieve high efficiency, high accuracy, and test methods. Simple and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

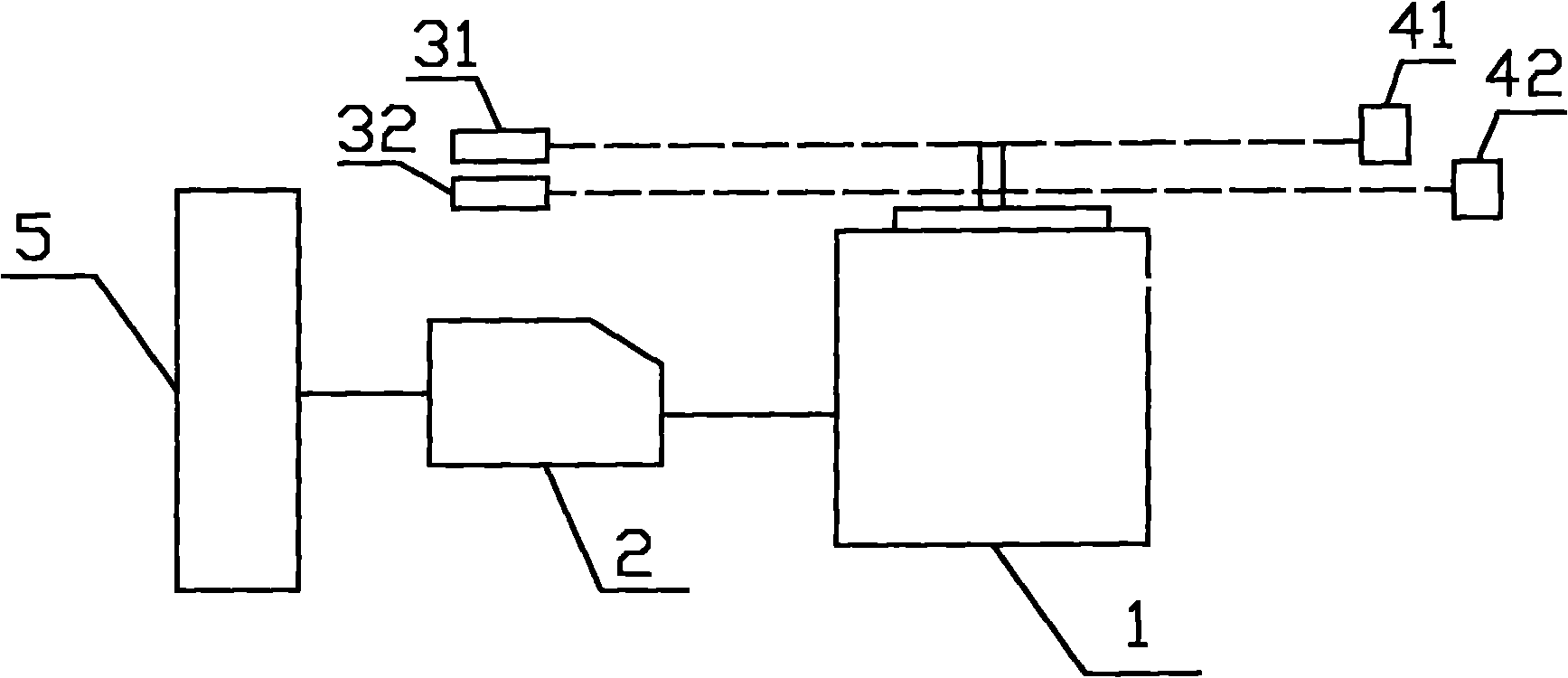

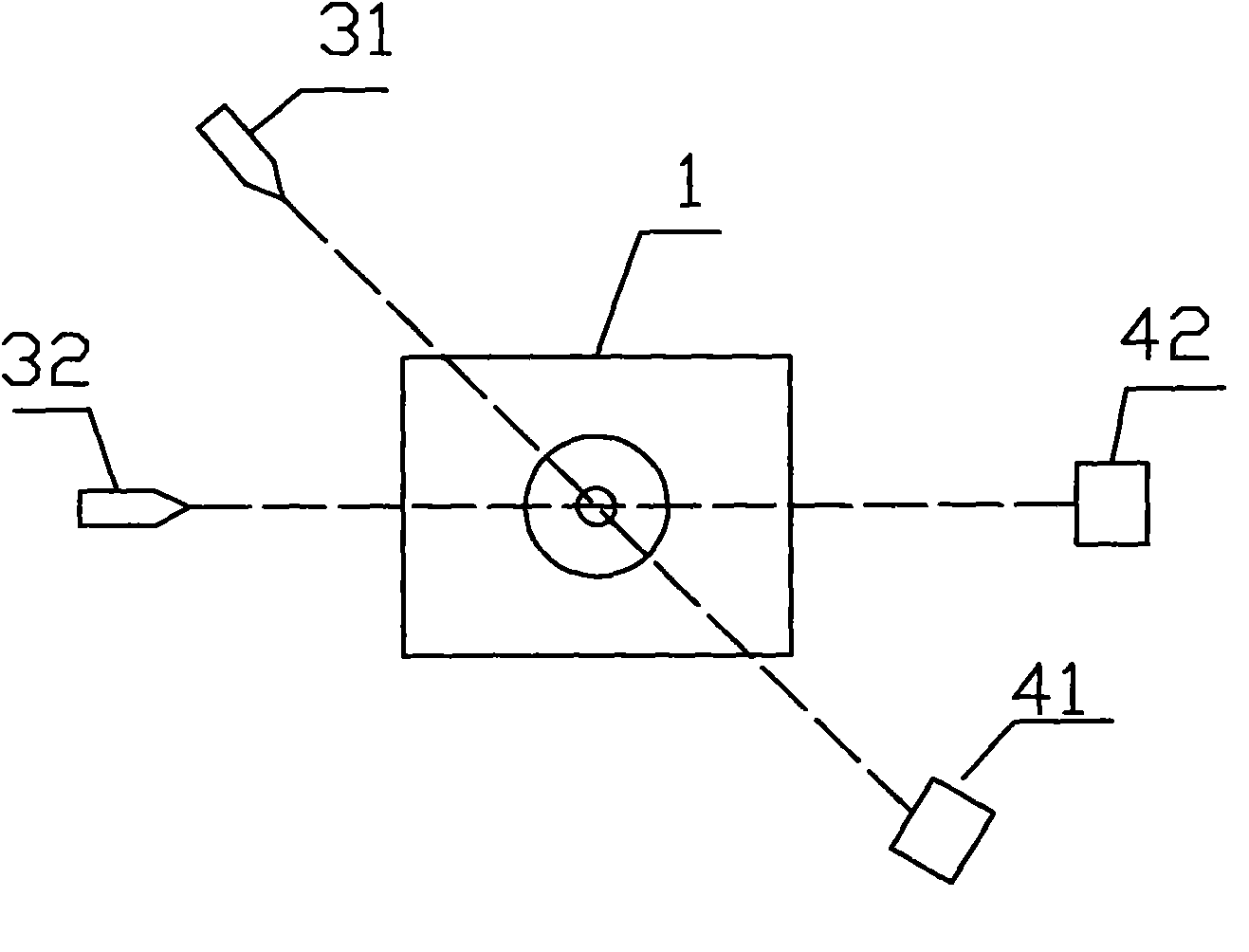

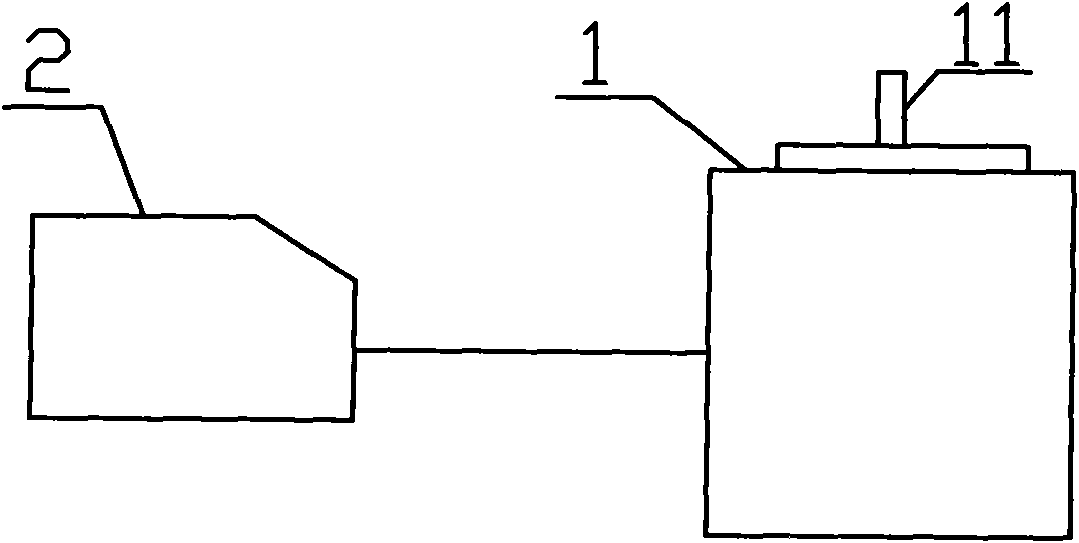

[0031] see figure 1 and figure 2 , implement the included device of the present invention to have: solenoid valve 1, solenoid valve control board 2, solenoid valve control board tester 5, laser emitter 31 and the photoelectric sensor 41 corresponding to the position, the photoelectric sensor corresponding to the laser emitter 32 and position 42, the photoelectric sensor 41 and the photoelectric sensor 42 can feed back the signal to the solenoid valve control board tester 5 after receiving the signal.

[0032] The method and steps of solenoid valve control board test of the present invention are as follows:

[0033] (1) First, two laser emitters 31, 32 and two photoelectric sensors 41, 42 are fixedly placed at different heights on both sides of the solenoid valve 1, and the laser emitter 31 and the photoelectric sensor 41 are correspondingly separated from the solenoid valve 1. The two sides of the solenoid valve 1 are at the same height; the laser emitter 32 is at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com