Method for preparing sensitive material In2O3/Nb2O5/Pt for composite nanometer semiconductor C12

A nano-semiconductor and sensitive material technology, which is applied in the synthesis of Cl2 sensitive materials, can solve the problems of poor sensitivity, high power consumption, and large volume of sensitive materials, and achieve the effects of improved characteristics, low power consumption, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

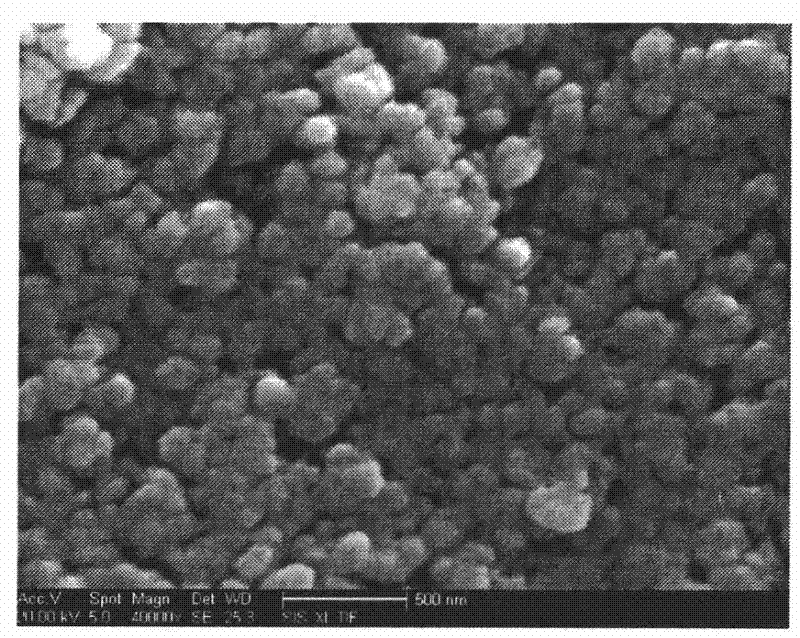

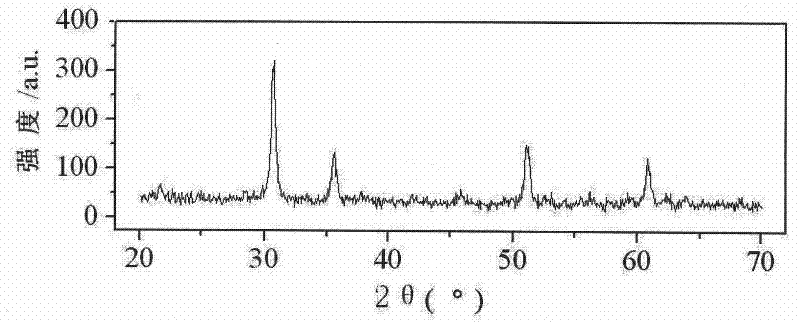

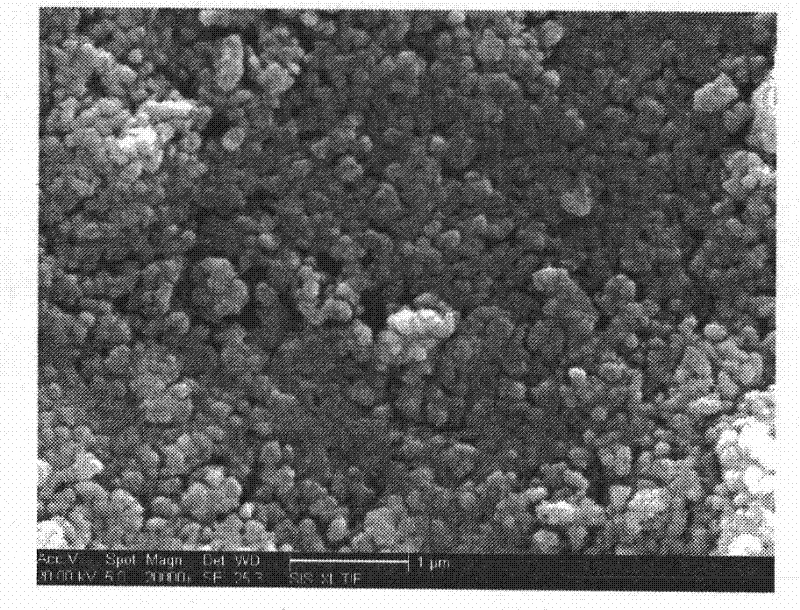

[0020] Specific embodiment one: this embodiment composite nano semiconductor Cl 2 Sensitive material In 2 O 3 / Nb 2 O 5 The preparation method of / Pt is carried out according to the following steps:

[0021] 1. Weigh InCl according to the molar ratio of 18:1 3 ·4H 2 O and Nb 2 O 5 , The InCl weighed first 3 Completely dissolve in deionized water to obtain InCl 3 Solution, weighed Nb 2 O 5 Add to HNO with a volume concentration of 18-22% 3 In, after filtration, with InCl 3 The solution was stirred and mixed, and NaOH with a mass concentration of 22%-28% was added to adjust the pH value of the mixture to 7.8-8.2, and then stirred at 48-52℃ for 4.8-5.2h to obtain a co-deposition mixture, in which InCl 3 ·4H 2 The mass ratio of O to deionized water is 2.93∶500, Nb 2 O 5 With HNO 3 The mass ratio is 1:3;

[0022] 2. The co-deposition mixture is centrifuged at 3000-5000r / min for 20-30min, the supernatant is removed, and then the precipitate obtained by centrifugation is washed with deioniz...

specific Embodiment approach 2

[0034] Specific embodiment two: This embodiment is different from specific embodiment one in that: in step one, NaOH with a mass concentration of 25% is added to adjust the pH value of the mixture to 8. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Specific embodiment three: This embodiment is different from specific embodiments one to two in that: in step one, it is stirred at 50° C. for 5 hours. The other steps and parameters are the same as those in the first to second embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com