Line insulation testing system

A test system and wire-to-line insulation technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of large test volume, low work efficiency, heavy manual operation burden, etc., to simplify design work and realize electrification control. , easy to control the effect of the target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below with reference to the accompanying drawings.

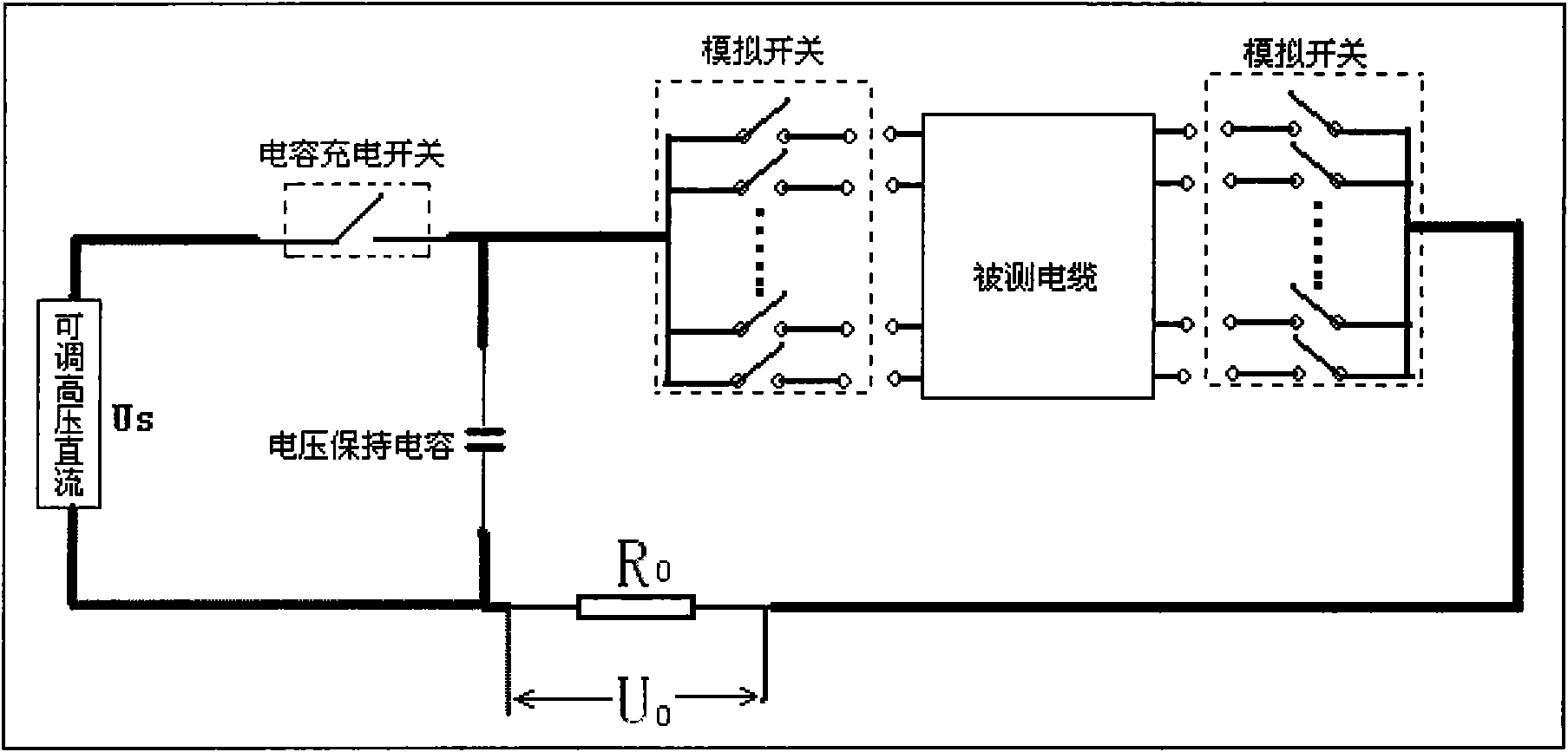

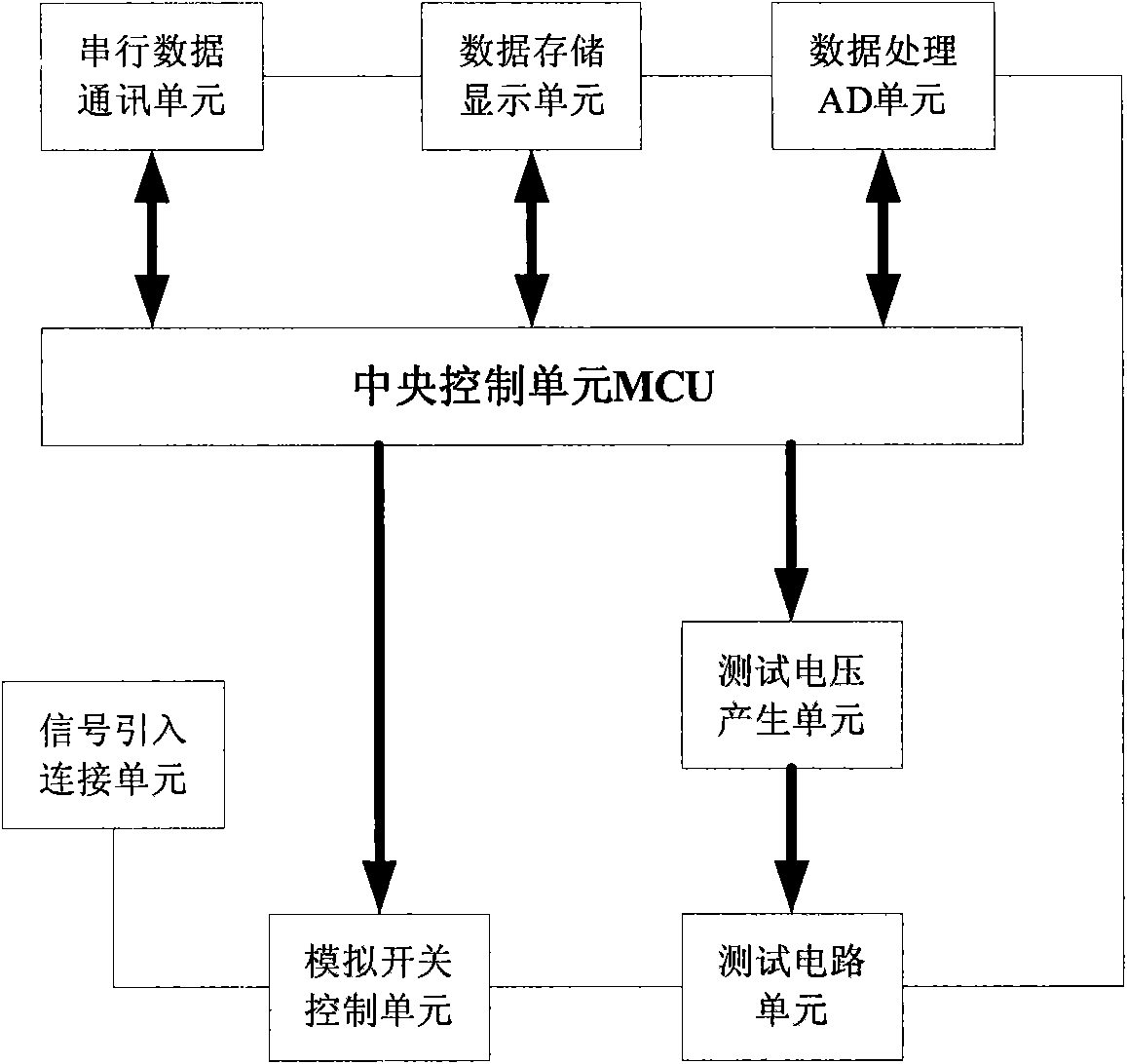

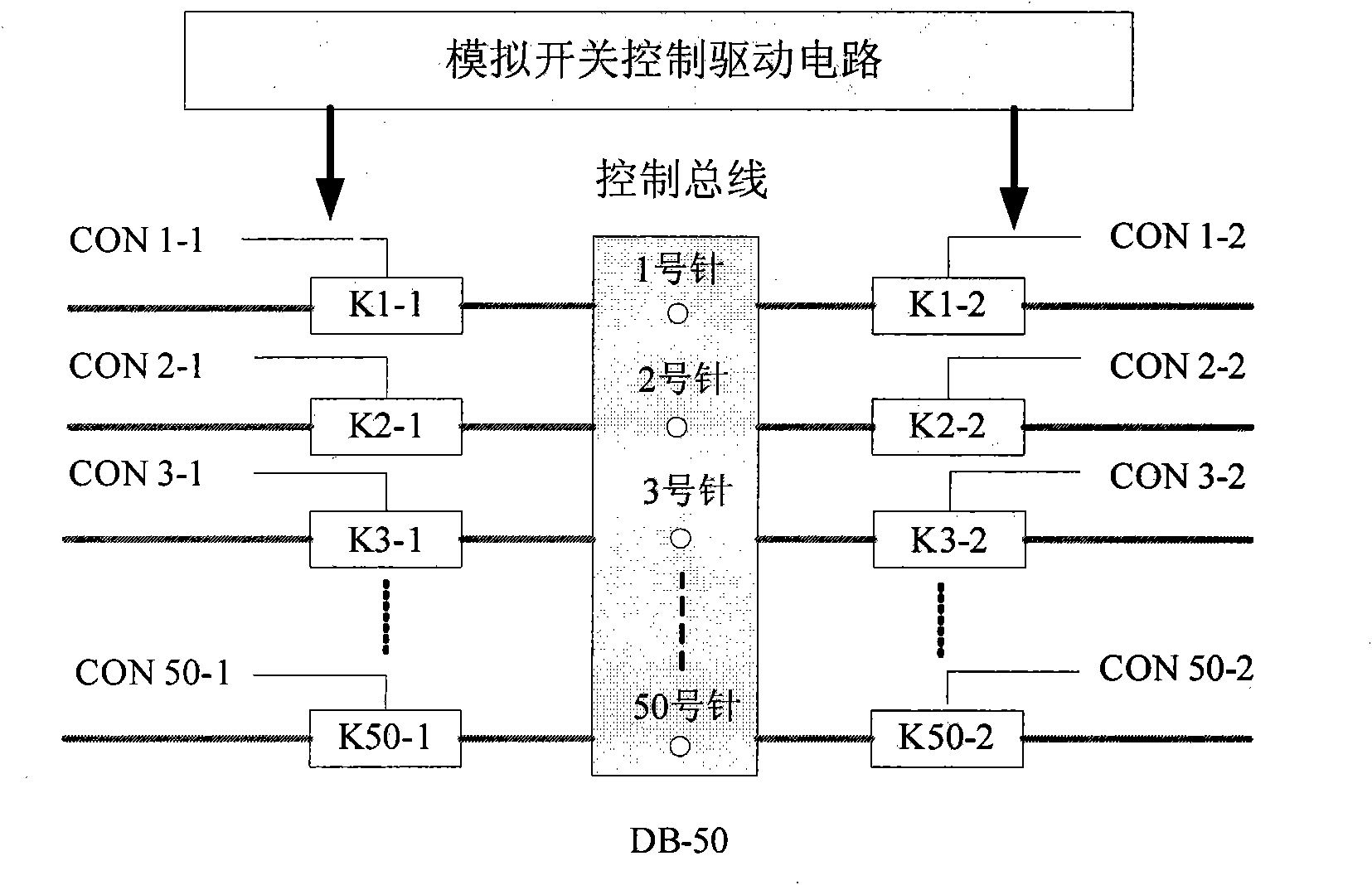

[0017] The testing principle of the present invention is as figure 1 As shown, firstly, the controller closes the capacitor charging control switch to charge the voltage holding capacitor through the adjustable DC voltage source, and after the completion, the controller turns off the switch. Then the controller closes the analog switches corresponding to the two groups of measured wires through the integrated control circuit, and enters the two wires with different numbers into the measurement circuit. At the same time, the controller starts AD to measure R 0 The voltage across the U 0 , the collection result is output to DSP, and the test result can be processed through the formula:

[0018] U S R 0 + R L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com