Autoclave-based creep age forming flexible frock

A technology of creep aging forming and flexible tooling, which is applied in the field of aviation manufacturing engineering, can solve the problems of forming force and pressure difference, and achieve the effect of compact structure, exquisite conception and high degree of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

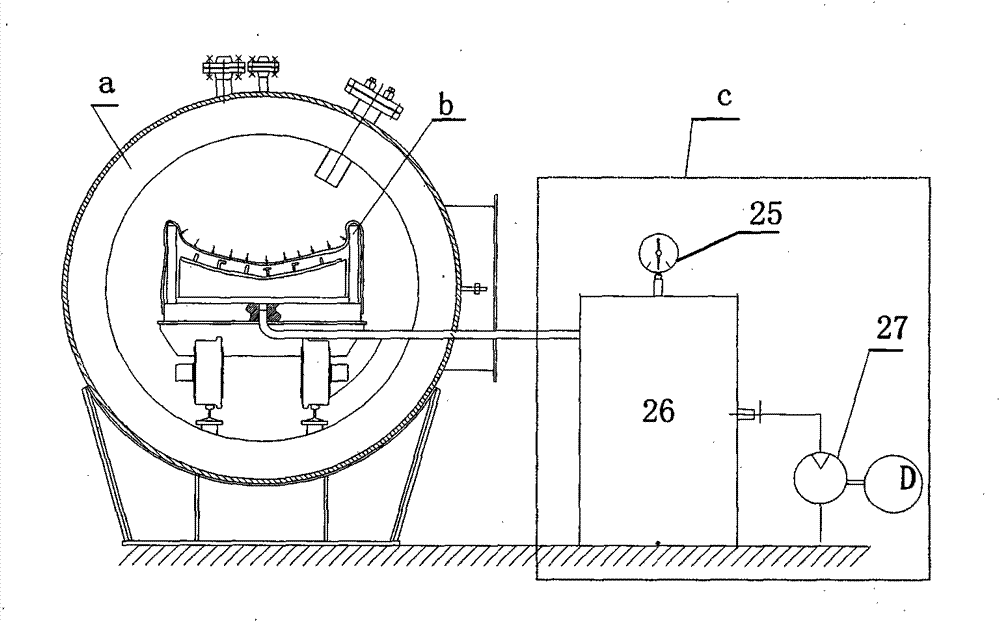

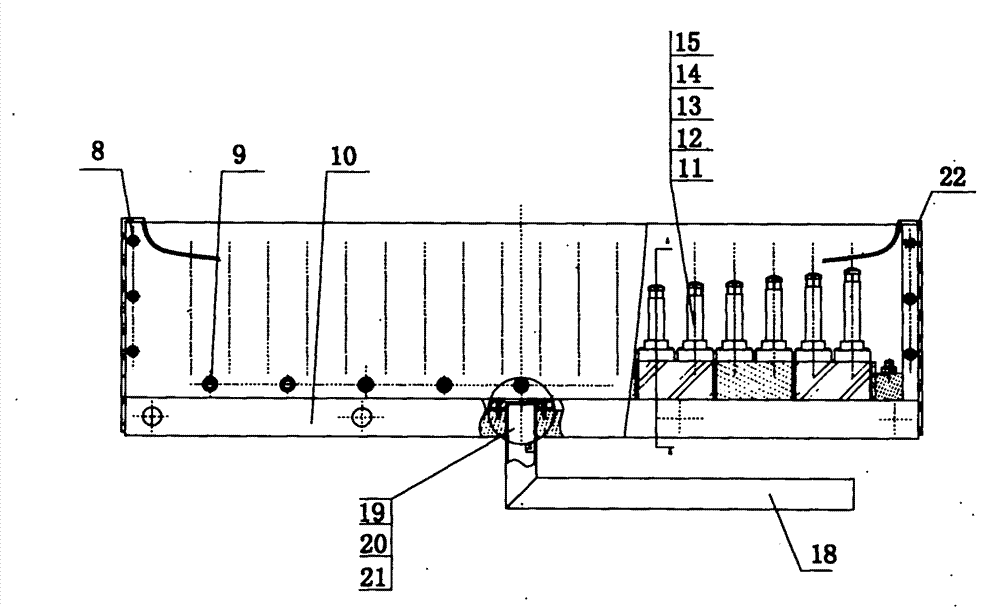

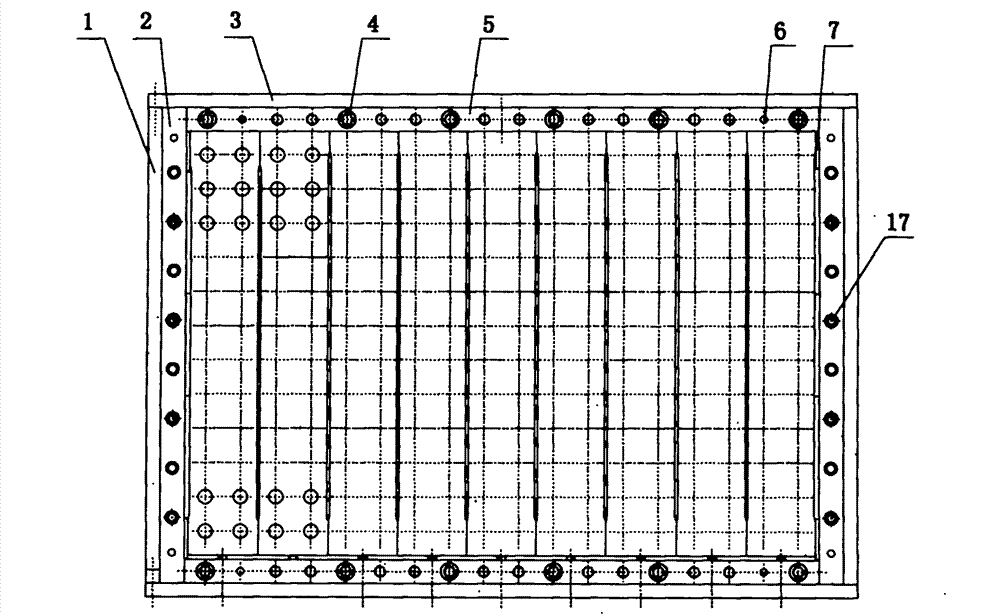

[0037] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] see Figure 2 to Figure 6 As shown, a kind of autoclave-based creep aging forming flexible tooling of the present invention specifically includes:

[0039] A vacuum bag 22, made of silicone cloth with a thickness of 0.07mm. This component is used to seal the parts to be formed and the mold. pressure,

[0040] A bottom plate 10 is drilled with pin holes and threaded holes,

[0041] A high frame is a frame composed of two short high frames 1 and two long high frames 3, and the vacuum bag 22 covers the high frame and the workpiece to be formed;

[0042] A low frame is a frame composed of two short low frames 2 and two long low frames 5, the high frame is fixed on the periphery of the low frame, and both the high frame and the low frame are fixed on the bottom plate 10;

[0043] Nail slats 14 are arranged side by side on the base plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com