Method for sealing transverse pipe tunnel and combined module component for implementing method

A technology of horizontal pipes and components, applied in the field of combined modular components, can solve the problems of affecting the effect of solid-sealing pipe holes and cumbersome procedures, and achieve the effects of rapid assembly and disassembly and repeated use, ensuring project quality and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

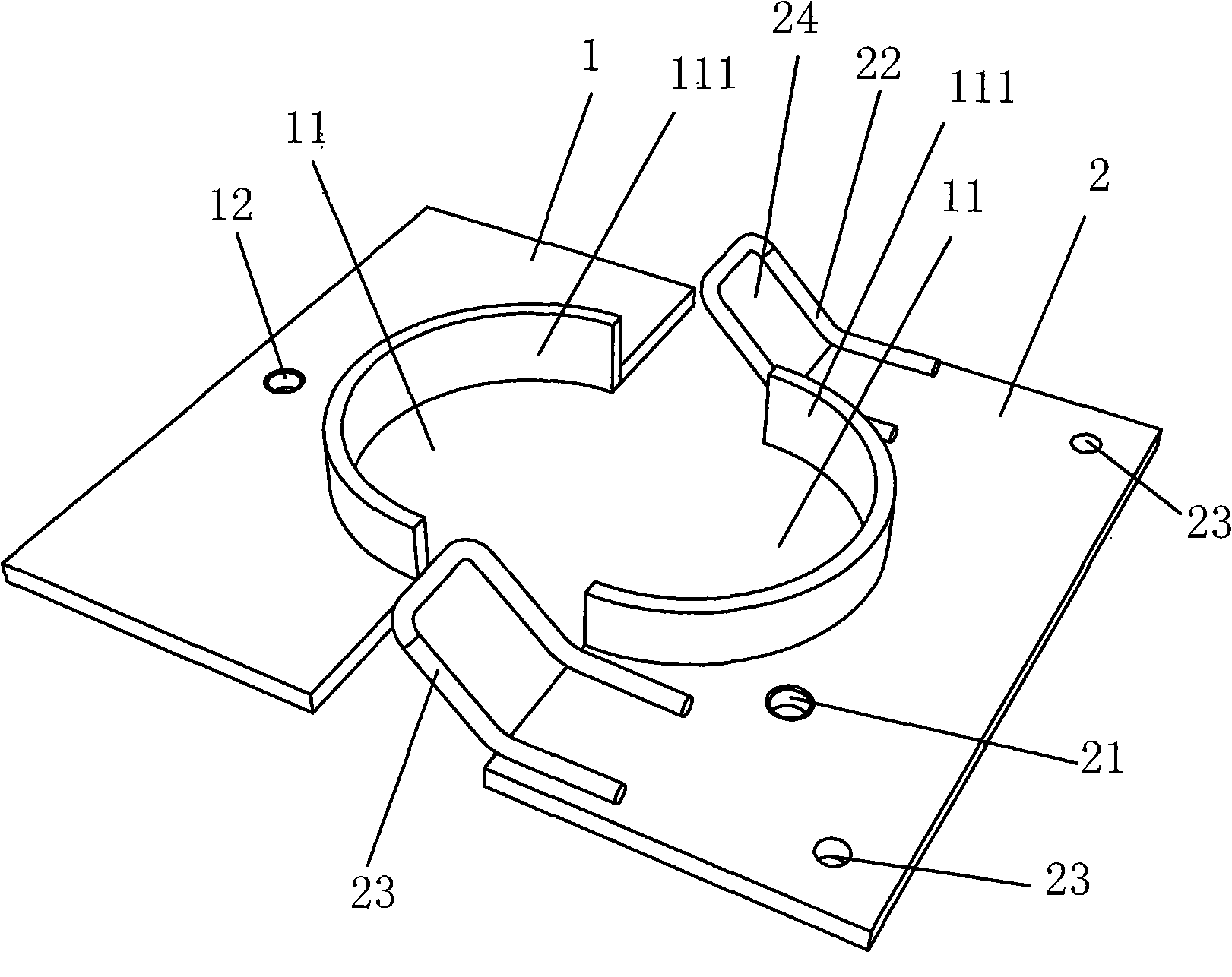

[0023] Example 1: see figure 1 , the present invention is a kind of method for sealing transverse pipe hole, it comprises the following steps:

[0024] (1) Two combined module components are set, and the combined module components include an upper support module 1 and a lower support module 2 used in combination, the upper support module 1 and the lower support module 2 are plate-shaped bodies, the upper support module 1 and the opposite side of the lower supporting module 2 are respectively provided with a semicircular notch 11 with the same diameter. circular opening on

[0025] (2) A grouting hole 21 that can be socketed on the grouting pipe is set on one side of the semicircular notch 11 of the lower supporting module 2, and a grouting hole 21 that can be connected to the upper semicircular notch 11 of the upper supporting module 1 is set. The exhaust hole 12 of the upper bleed pipe is sleeved;

[0026] (3) Several locking devices capable of connecting and locking the u...

Embodiment 2

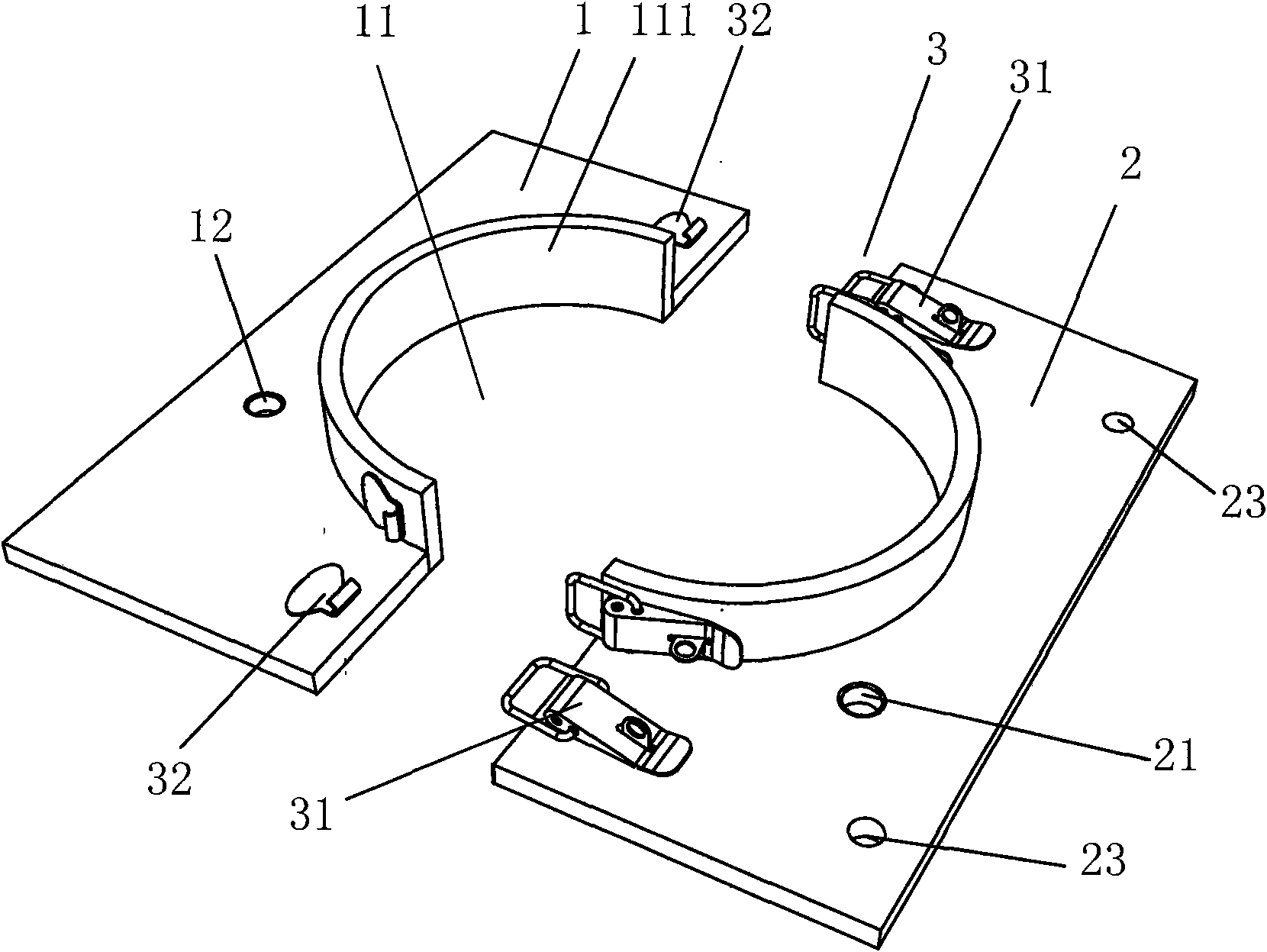

[0034] Example 2: see figure 2 , the present invention is a kind of method for sealing transverse pipe hole, it comprises the following steps:

[0035] (1) Two combined module components are set, and the combined module components include an upper support module 1 and a lower support module 2 used in combination, the upper support module 1 and the lower support module 2 are plate-shaped bodies, the upper support module 1 and the opposite side of the lower supporting module 2 are respectively provided with a semicircular notch 11 with the same diameter. circular opening on

[0036] (2) A grouting hole 21 that can be socketed on the grouting pipe is set on one side of the semicircular notch 11 of the lower supporting module 2, and a grouting hole 21 that can be connected to the upper semicircular notch 11 of the upper supporting module 1 is set. The exhaust hole 12 of the upper bleed pipe is sleeved;

[0037](3) Several locking devices capable of connecting and locking the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com