Tower type combined drive pumping unit without guide wheel

一种组合传动、抽油机的技术,应用在传动装置、机械设备、皮带/链条/齿轮等方向,能够解决影响制约大规模的推广与应用、抽油杆和井口损坏、不能同时处理好等问题,达到设备紧凑、减少动力损失、重心平稳的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

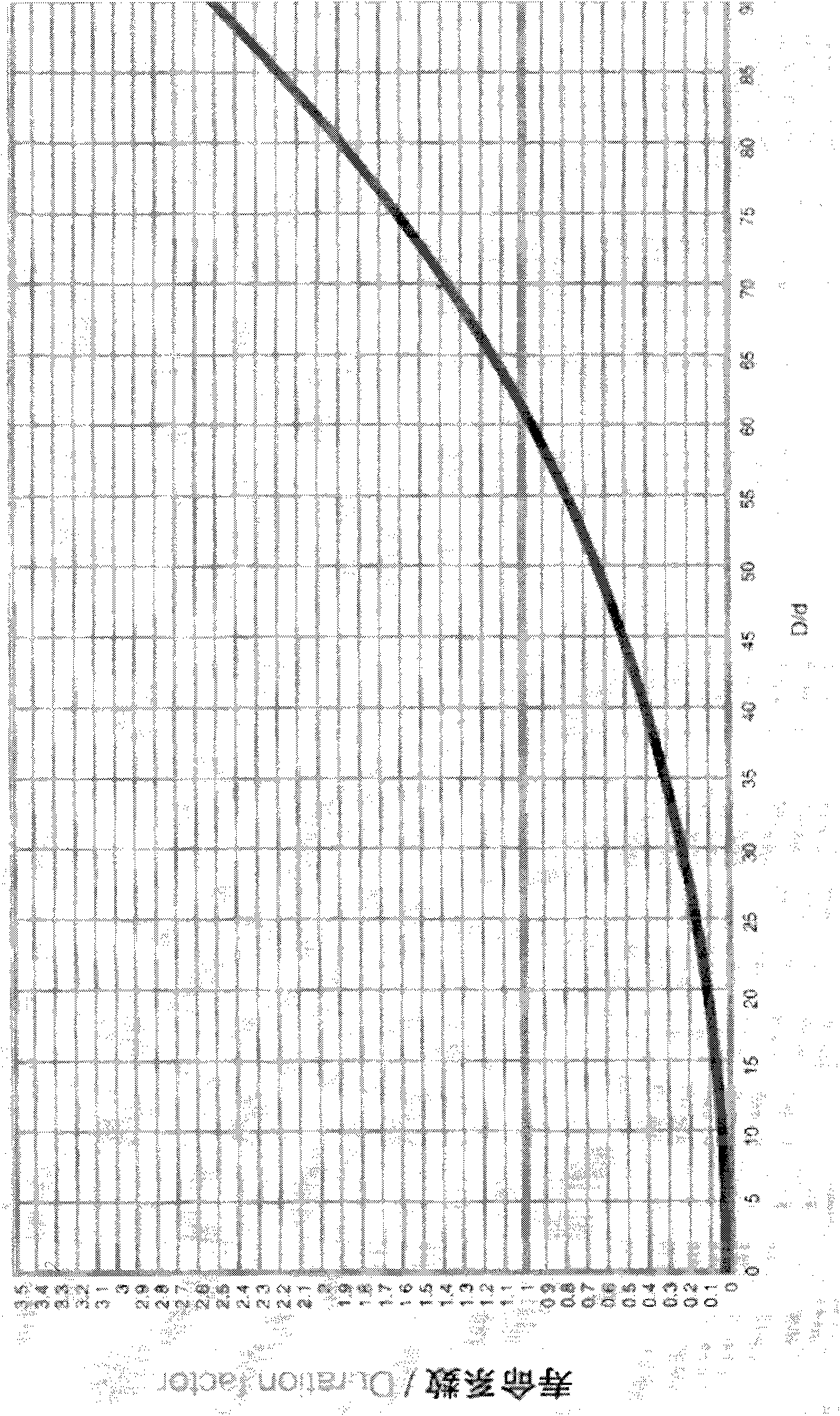

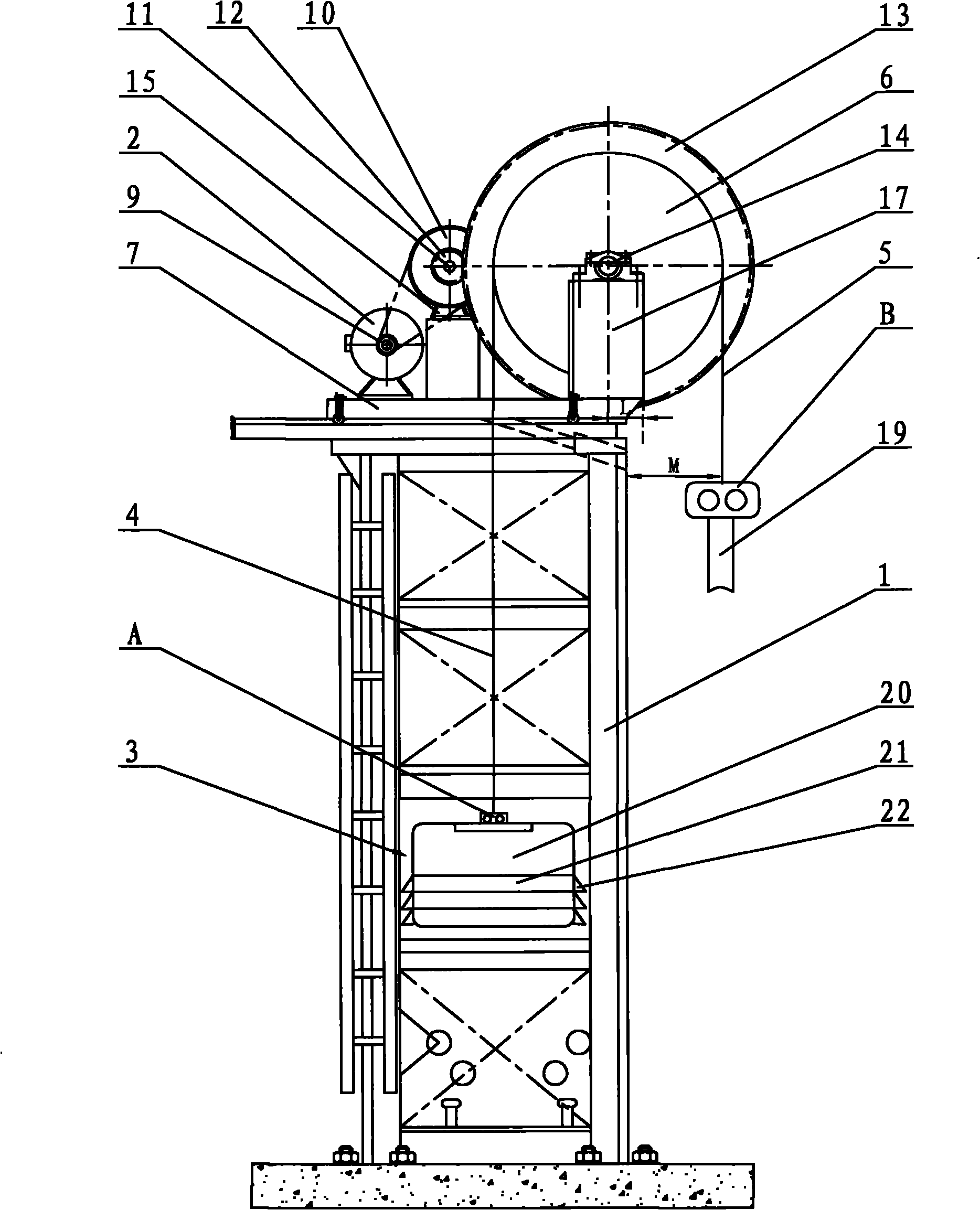

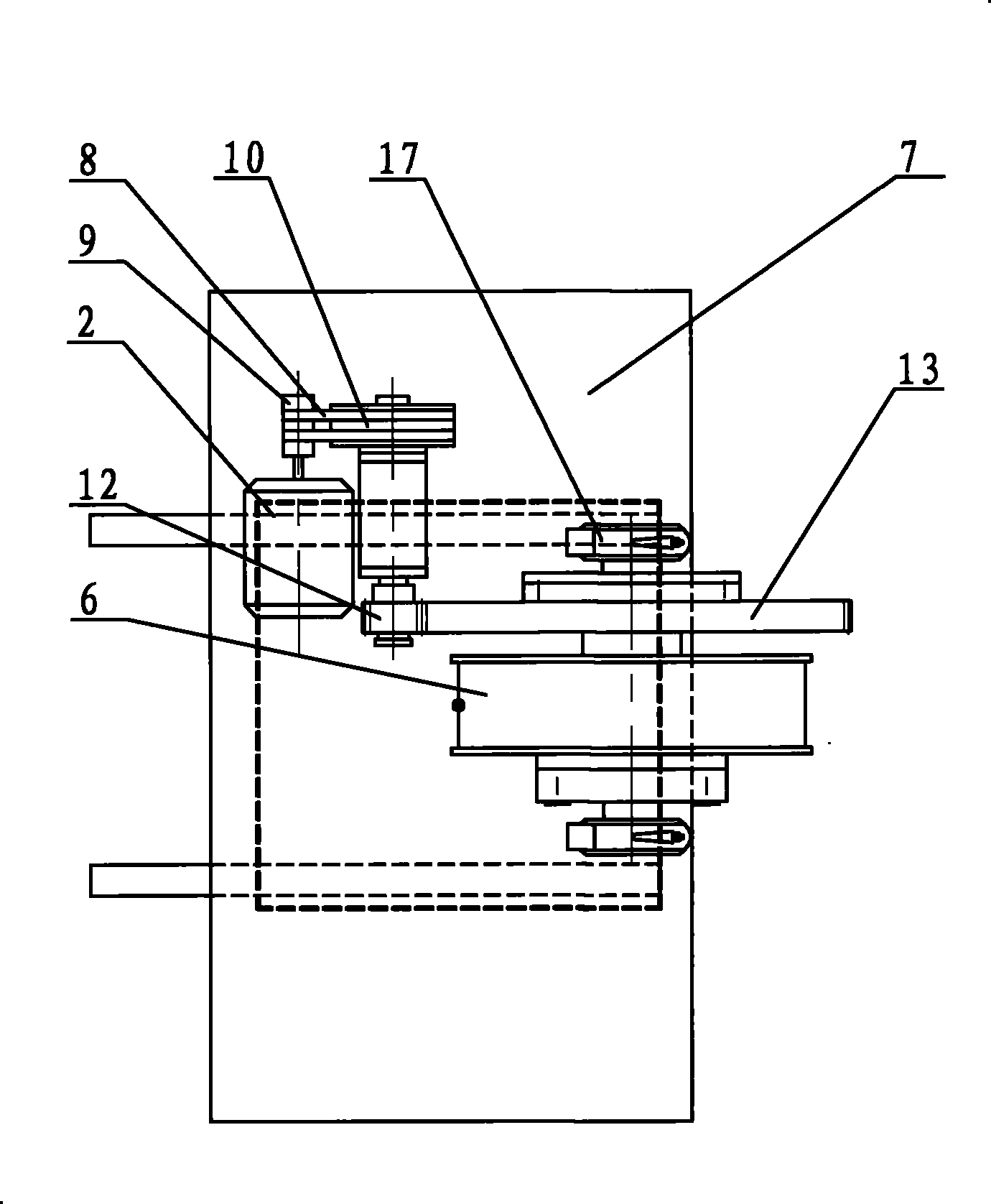

[0023] like figure 2 and image 3 The shown tower type combined transmission pumping unit without guide wheels is the first embodiment of the present invention, including a tower 1, a power system 2, a transmission system, a control system, a balance counterweight box 3, a counterweight traction rope 4, Drive rope 5 and rope hanger, wherein power system 2, transmission system and sheave 6 are installed on the operating platform 7 on the top of tower 1, power system 2 is permanent magnet synchronous brake motor, and control system is installed on permanent magnet synchronous brake motor. In the motor, the staff can control and operate the entire tower-type guide wheel-less combined transmission pumping unit under the tower 1 through the wireless or wired controller of the control system. combine Figure 5As shown, the transmission system includes a transmission belt 8, a small belt sprocket 9, a large belt sprocket 10, a transmission shaft 11, a pinion 12, a large gear 13 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com