Control circuit and method of capacitance type touch control panel and capacitance type touch control panel module

A technology of capacitive touch control and control circuit, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of insignificant capacitance change, reduced performance, difficult induction, etc., and achieve wide detection range, large capacitor dielectric thickness, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

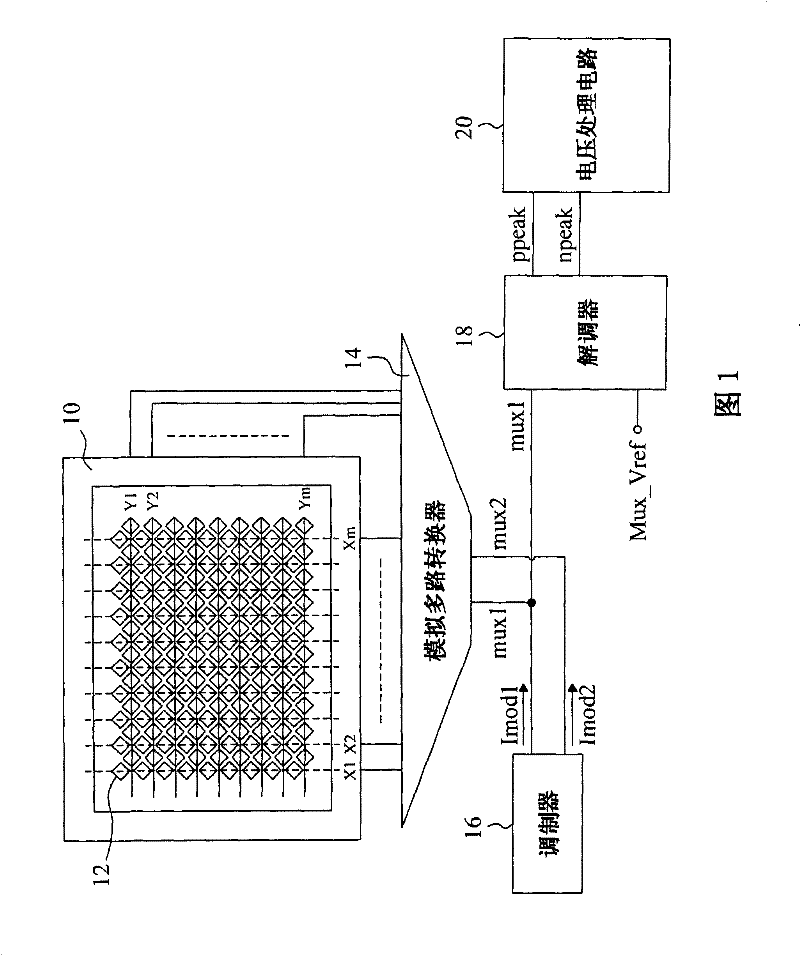

[0063] figure 1It is a schematic diagram of an embodiment of the present invention. There are multiple sensors 12 on the capacitive touch panel 10. The vertical sensors 12 are connected by wires to form traces (trace) X1, X2...Xm, and the horizontal sensors 12 also form the trace lines Y1, Y2...Ym respectively, the current signal generated by the modulator 16 selects the trace to be connected to through the analog multiplexer 14, and modulates into signals mux1 and mux2, and the demodulator 18 uses the reference signal Mux_Vref The signal mux1 is demodulated to generate signals ppeak and npeak to the voltage processing circuit 20 , and the voltage processing circuit 20 converts the voltage difference between the signals ppeak and npeak to obtain capacitance change information on the capacitive touch panel 10 .

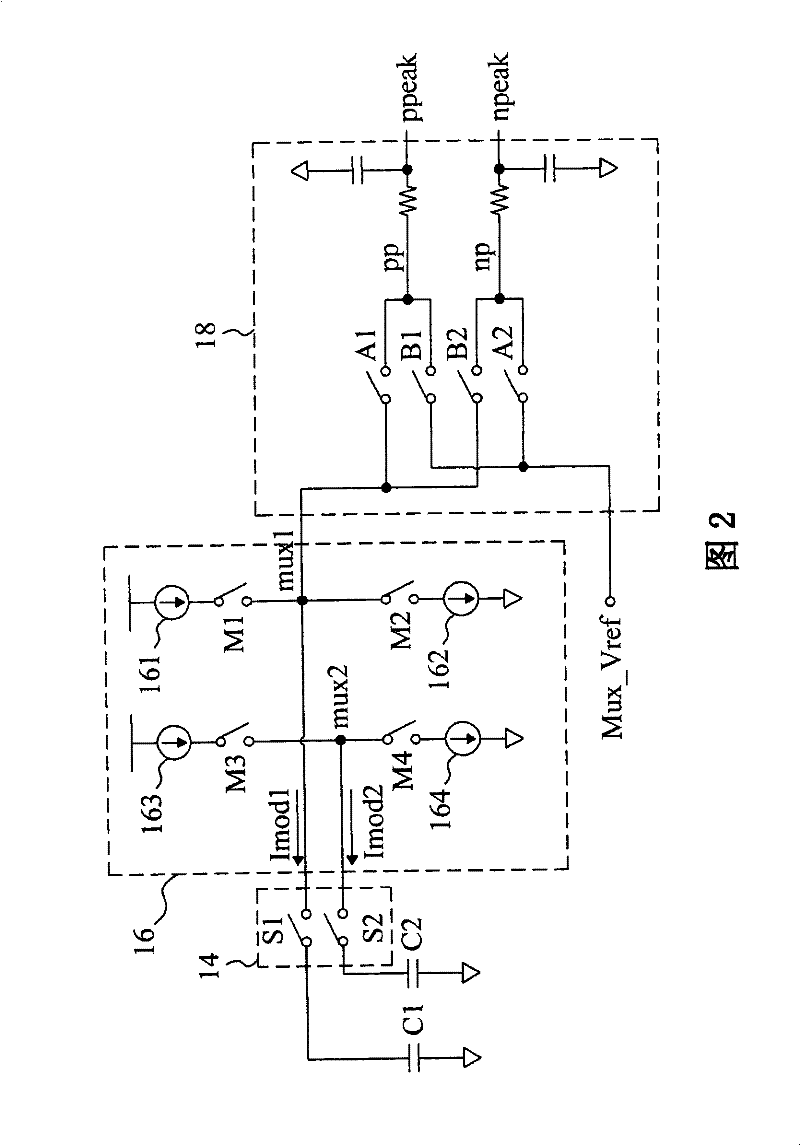

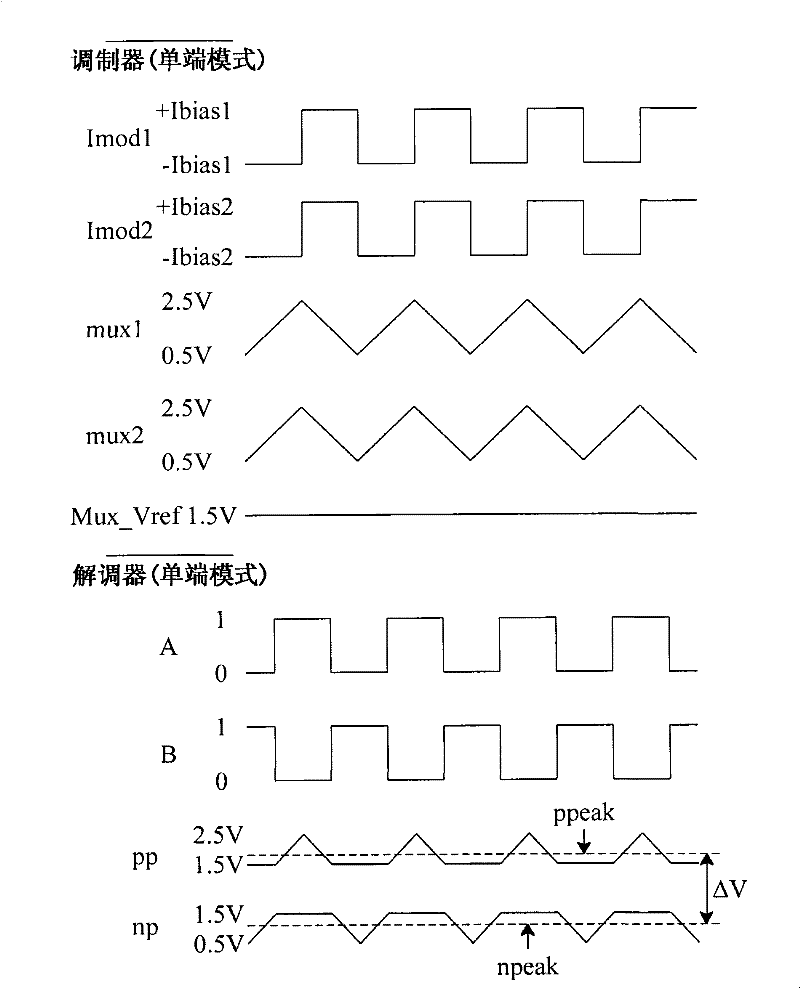

[0064] figure 2 for figure 1 The circuit diagram of the embodiment, image 3 The single-ended signal waveform diagrams in the modulator and demodulator are shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com