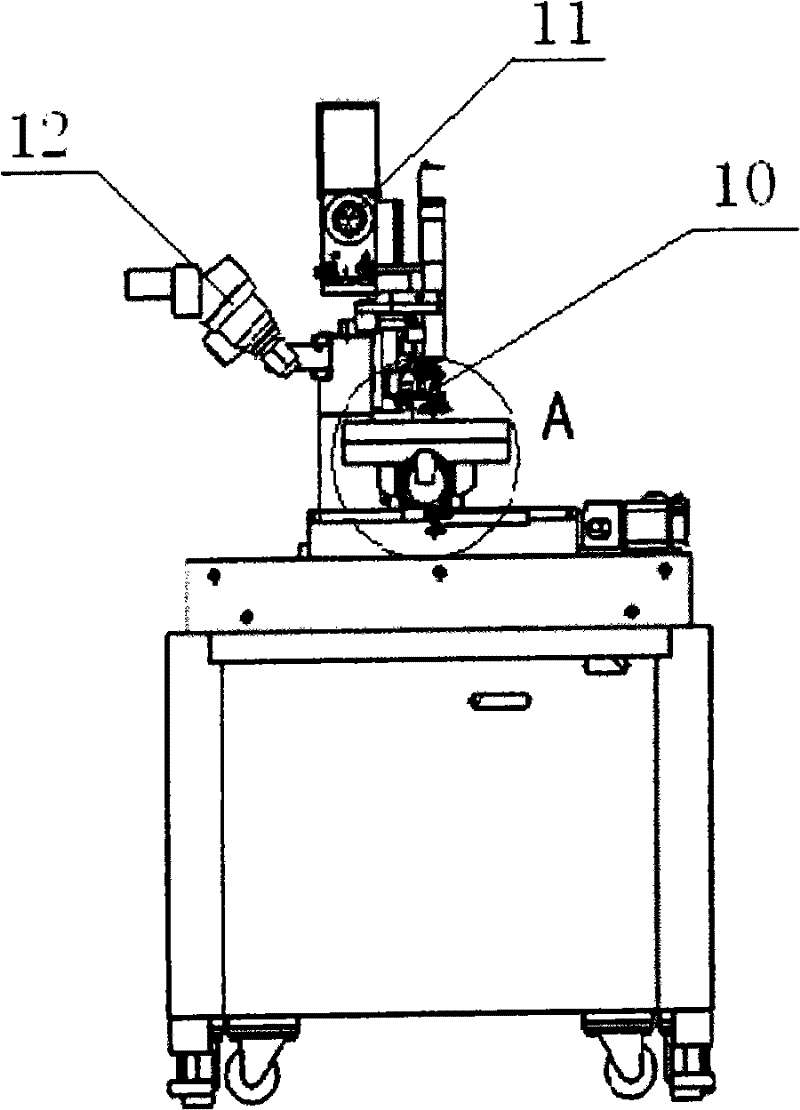

Light emitting diode (LED) magnetic adsorption and positioning aluminum wire bonding machine with cross guide rail transfer table

A cross guide rail and magnetic adsorption technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of inability to meet processing requirements, unstable welding quality, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

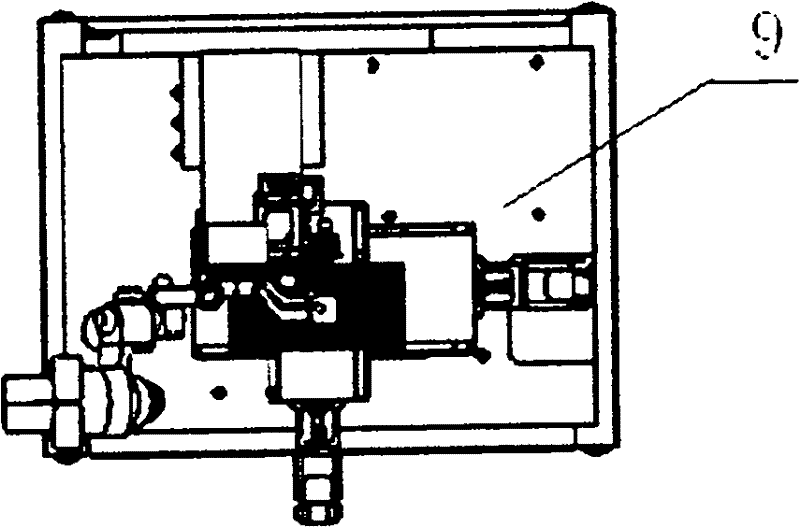

Method used

Image

Examples

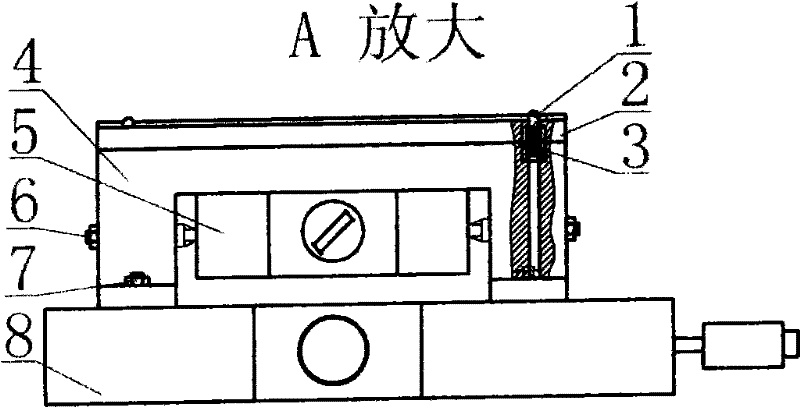

Embodiment Construction

[0013] Firstly, place the cross rail shift table on the given position of the base plate of the LED cross rail shift table magnetic adsorption positioning aluminum wire punching machine, and use the cross rail shift table connecting screws to realize the fixed connection between the cross guide rail shift table and the machine base. Type positioning pin on the upper surface of the bridge-type support seat, and then place the magnet of the magnetic table base in the center of the bridge-type support seat, and make the upper surface of the magnetic table base flat with the bridge-type support seat, and fix the magnetic table base with the fixing screw. The table base is fixed with the bridge-shaped support seat, and then the bridge-shaped support seat with the magnetic table base fixed and the cross guide rail moving table are fixed with connecting screws. Then the pressure spring is put into the evenly distributed spring seat holes on the bridge-shaped bearing seat, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com