Equalizing charge method and equalizing charger

A technology of balanced charging and charging detection, which is applied in the direction of secondary battery charging/discharging, current collectors, battery circuit devices, etc., can solve the problems of high cost of detection circuits, floating detection circuits, unsuitable lead-acid batteries, etc., to ensure charging effect, ensure consistency, and realize the effect of intelligent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (Embodiment 1, balanced charging method)

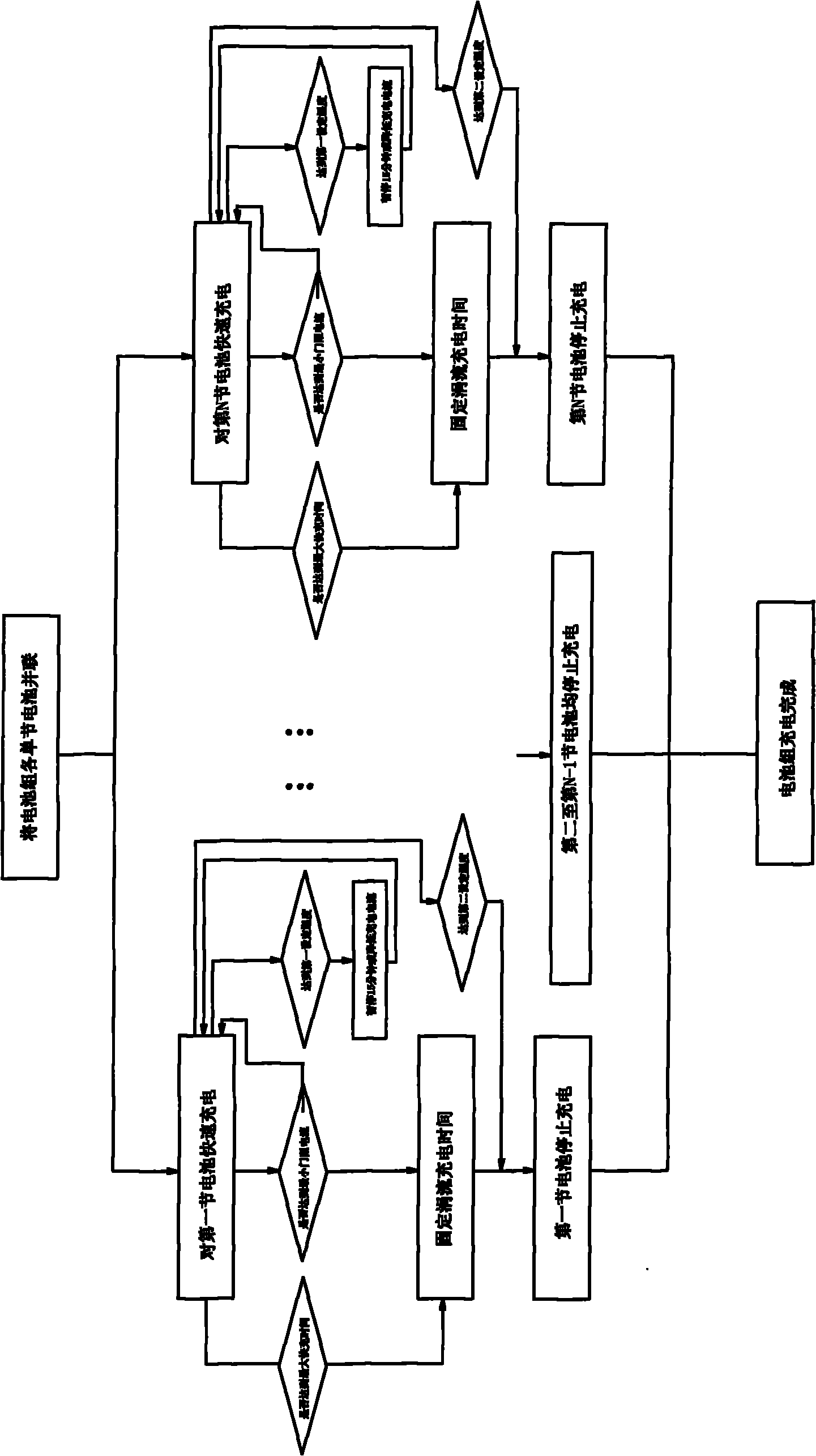

[0055] See figure 1 , the balanced charging method of the present embodiment, its core is to connect each single battery of the battery pack in parallel, and then the single-chip microcomputer controls each battery to charge simultaneously. Specifically, the steps of equalizing charging are as follows:

[0056] ① Connect N (N is an integer, N≥2) single cells in the battery pack in parallel. The positive poles of each battery are drawn out with wires, and the negative poles are connected together and lead out with a common wire, thereby forming N batteries in parallel. In this embodiment, a parallel mode can be formed through the charging and discharging conversion joint.

[0057] ②At the same time, independently and quickly charge N cells. In this step, the 220V power supply charges the first battery after being rectified, filtered, up-frequency and transformed. The single-chip microcomputer performs N-channel pulse width ...

Embodiment 2

[0061] (Embodiment 2, balanced charging method)

[0062] still see figure 1 In this embodiment, on the basis of the method in Embodiment 1, the monitoring of the temperature during the charging process of the battery is added to protect the rechargeable battery and avoid over-current and over-temperature phenomena.

[0063] In this embodiment, while charging each battery in step ② of Embodiment 1, the temperature detection circuit also collects the temperature of each battery in real time, and feeds back the collected temperature data of the corresponding battery to the The single-chip microcomputer compares and controls it with the first temperature setting value and the second temperature setting value. When the first temperature setting value is reached, the single-chip microcomputer controls to reduce the charging current of the battery or temporarily stop charging the battery. The single battery is charged for 15 minutes, and then the minimum threshold current is judged ...

Embodiment 3

[0065] (Embodiment 3, balanced charger)

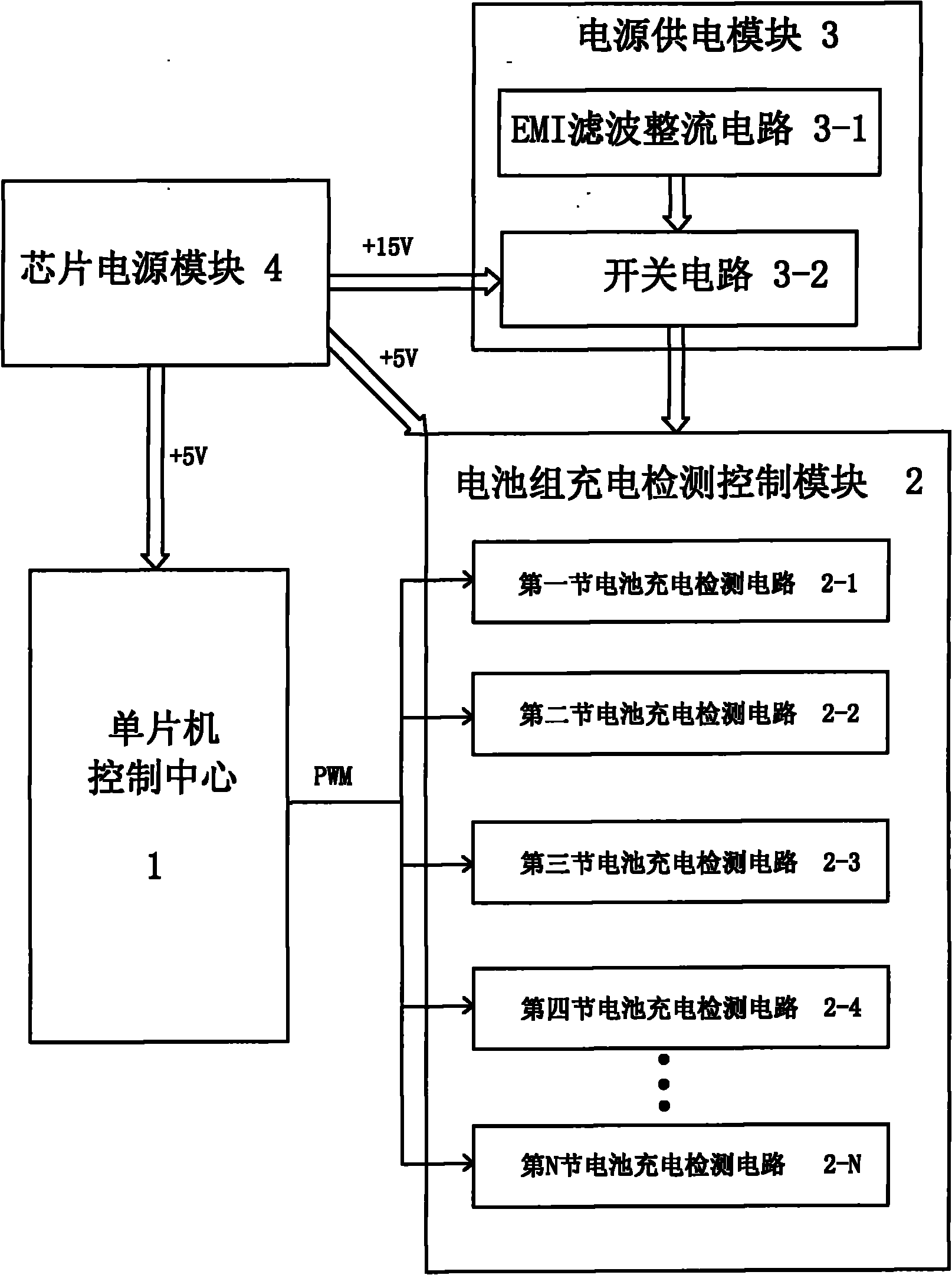

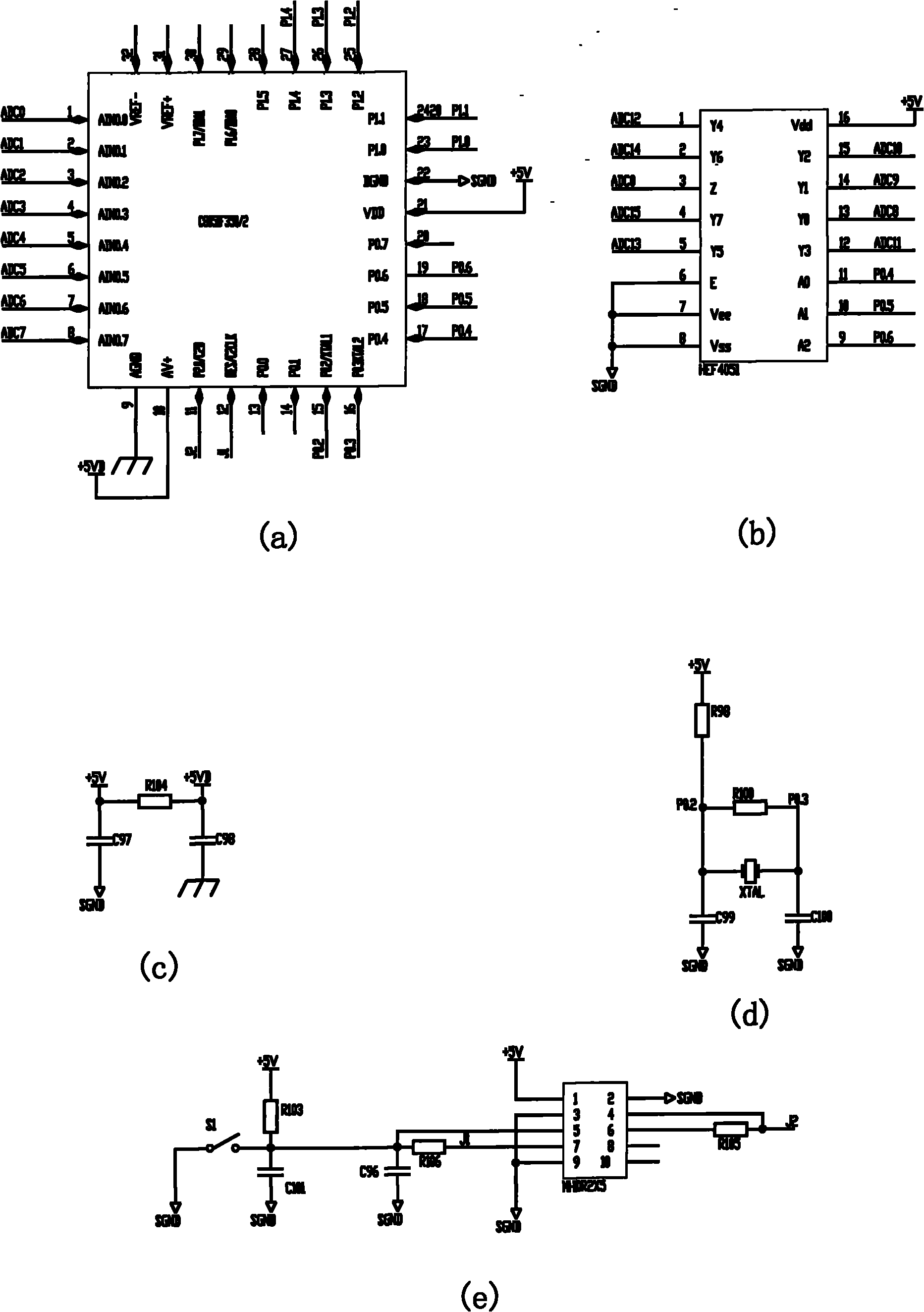

[0066] See figure 2, The balanced charger of this embodiment includes a single-chip microcomputer control center 1, a battery pack charging detection control module 2, a power supply module 3 and a chip power module 4. The power supply module 3 is electrically connected to the battery pack charging detection control module 2; the single-chip microcomputer control center 1 is electrically connected to the battery pack charging detection control module 2, and controls the battery pack charging detection control module 2 through multiple pulse width modulation outputs; the chip power module 4 is electrically connected with the chips in the single-chip microcomputer control center 1, the battery pack charging detection control module 2 and the power supply module 3. The battery charge detection control module 2 includes N (N is an integer, N≥2) single batteries connected in parallel and a battery charge detection circuit 2-1 - 2-N corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com