BTB (Board to Board) connector

A technology of connectors and docking grooves, which is applied in the direction of connecting/disconnecting connected parts, contact parts, electrical components, etc., which can solve the problems of small contact force, low contact stability, large contact resistance, etc., and achieve elastic contact force Large, good contact stability, and small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

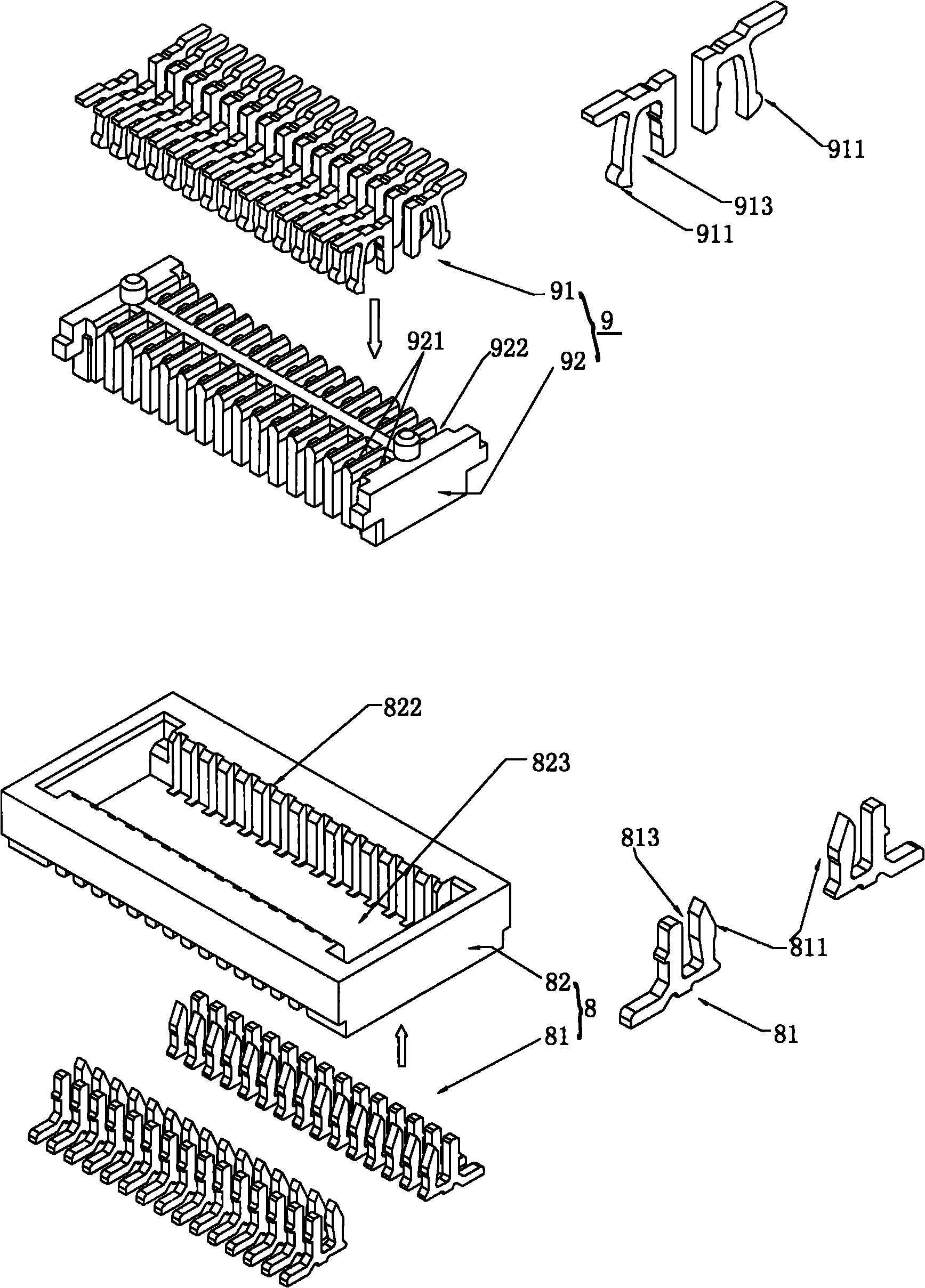

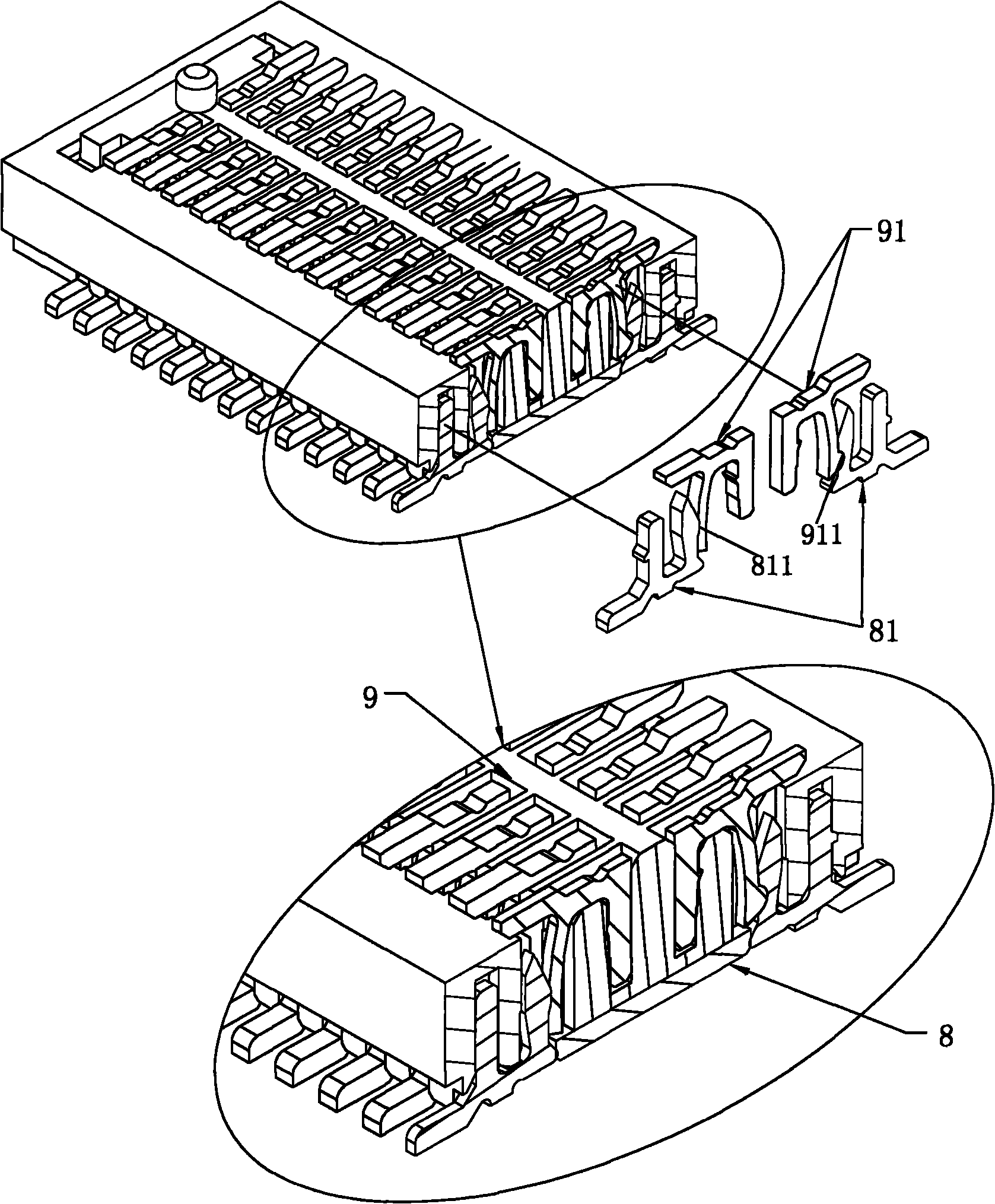

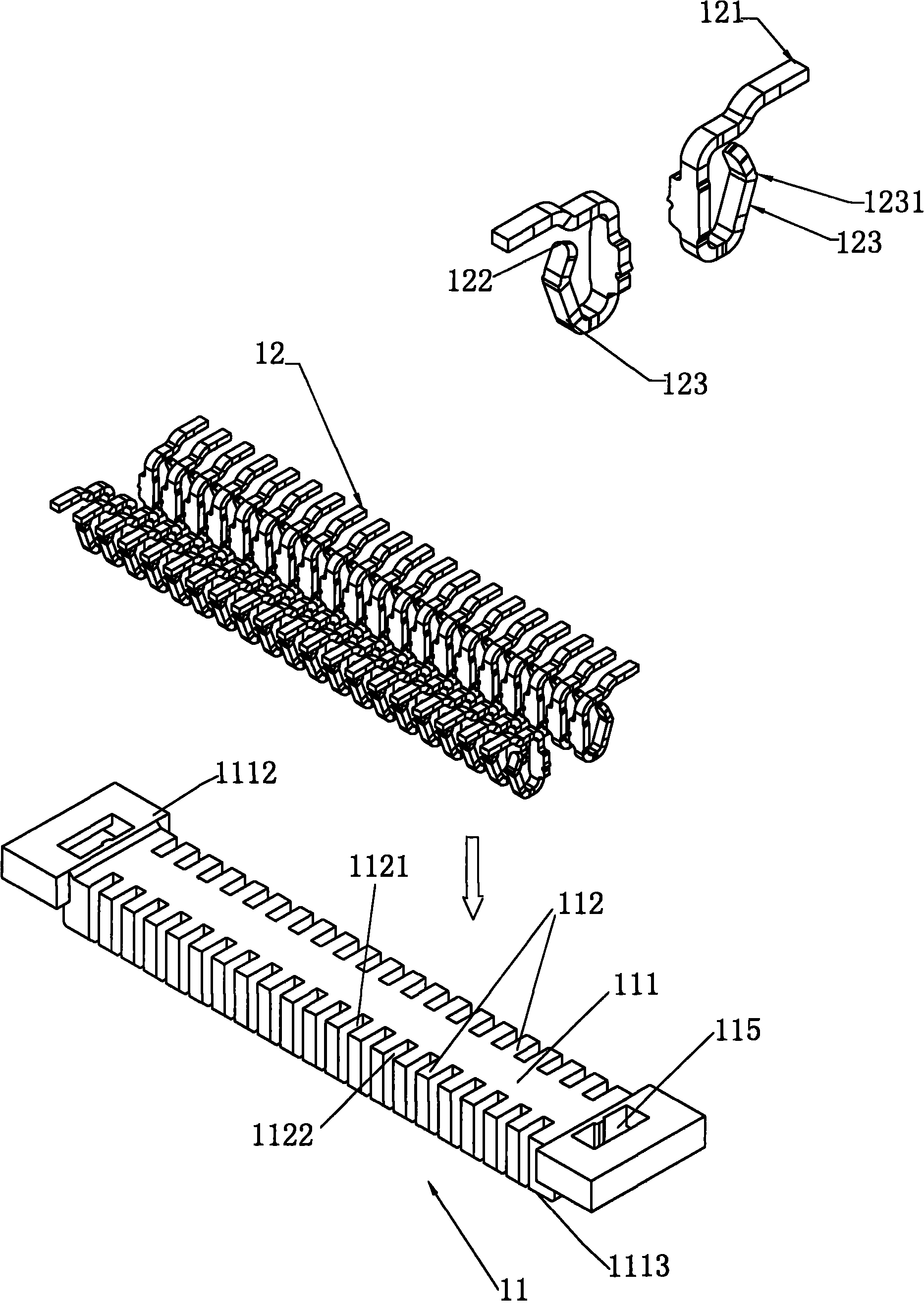

[0032] In order to make the structure, features and advantages of the BTB connector of the present invention be further understood, it will be described in detail below in conjunction with the accompanying drawings:

[0033] The BTB connector of the present invention includes several male terminals combined with the male body and female terminals combined with the female body. The main body of the male end and the female end are insulating block structures, and a docking groove is provided on the main body of the female end for docking insertion of the main body of the male end. The male and female terminals are bent and formed on the main body of the terminal made of metal material, and each terminal has a longer elastic force arm respectively, forming a contact area on the elastic force arm. During the process of butt-butting and pressing the male-end main body into the docking groove of the female-end main body, the elastic arms of the male and female terminals squeeze each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com