Drive circuit for realizing accurate constant current of multiple LEDs

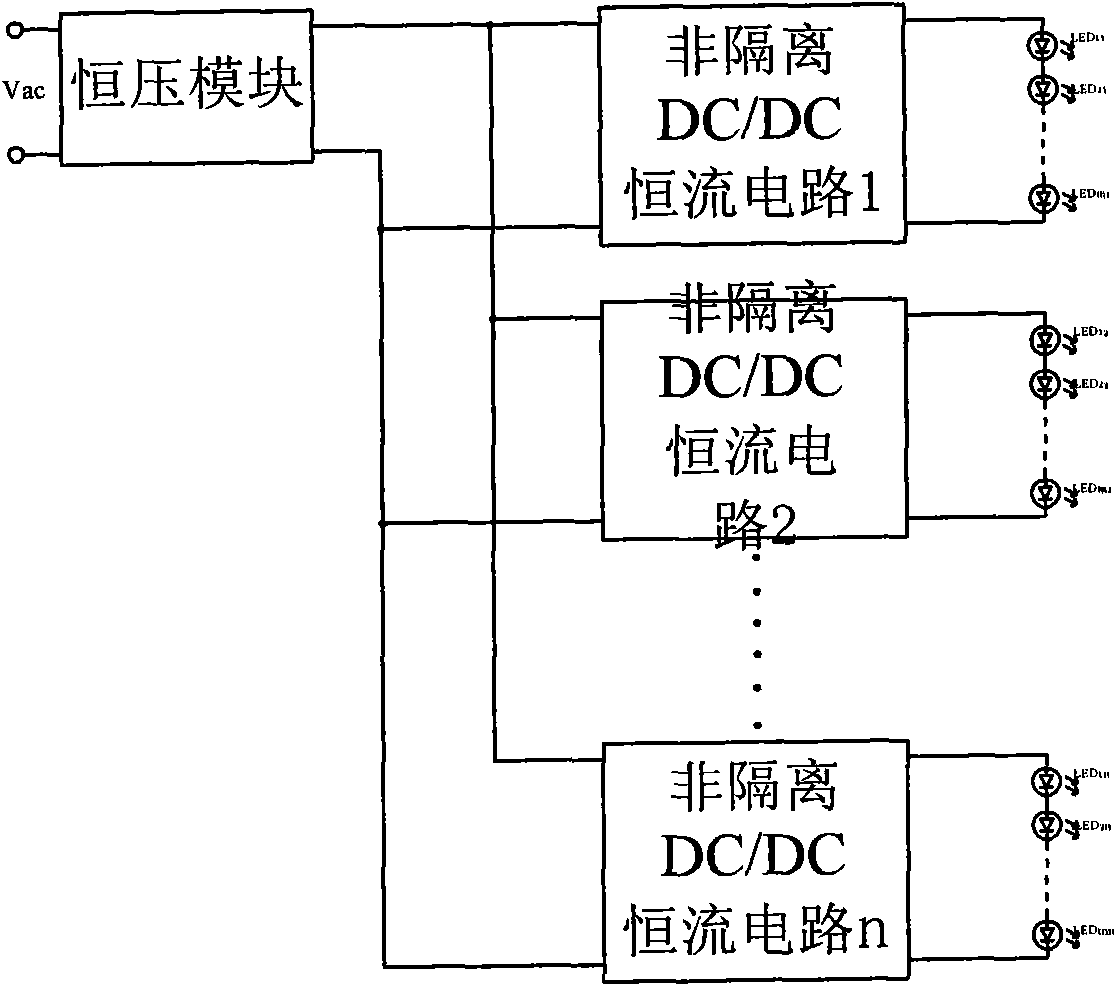

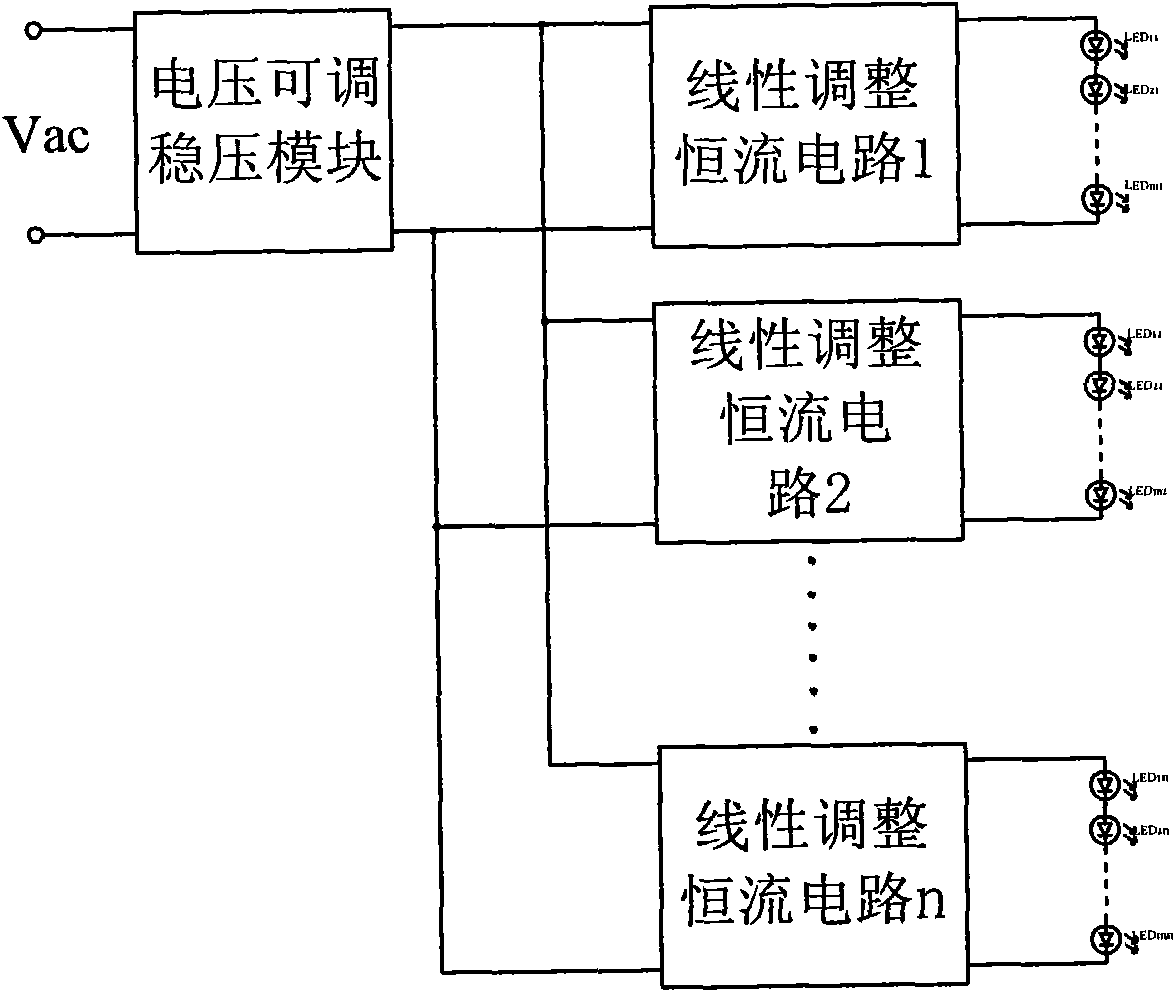

一种驱动电路、整流滤波电路的技术,应用在电灯电路布置、电光源、电气元件等方向,能够解决LED驱动器发热、线性调整管功耗大等问题,达到可靠性高、成本低、效率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

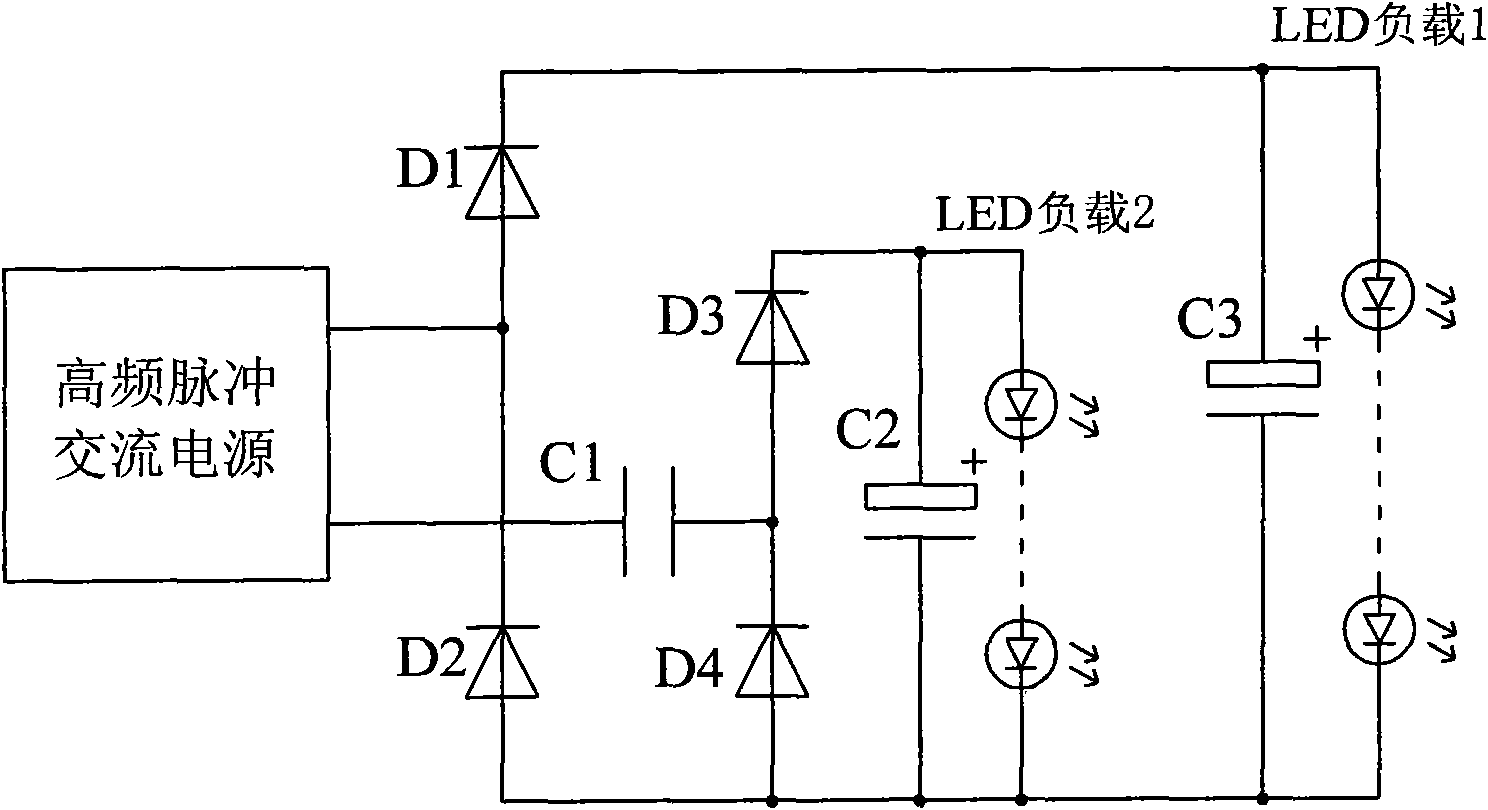

[0039] refer to image 3 , a drive circuit that realizes accurate constant current of multiple LEDs, and realizes the balance of load currents of two LEDs. The first circuit is characterized in that: one end of the high-frequency pulsed AC power supply is connected to the anode of diode D1 and diode D2 The cathode of the high-frequency pulse AC power supply is connected in series with a DC blocking capacitor C1, the other end of the capacitor C1 is connected to the anode of the diode D3 and the cathode of the diode D4, the anodes of the diodes D2 and D4 are connected, and the positive terminal of the LED load 1 is connected to the diode D1 The negative terminal of LED load 1 is connected to the anodes of diodes D2 and D4, the positive terminal of LED load 2 is connected to the cathode of diode D3, the negative terminal of LED load 2 is connected to the anodes of diodes D2 and D4, and the filter capacitors C2 and C3 are connected in parallel At both ends of the two LED loads. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com