Device for damping vibrations, in particular a multi-step torsional vibration damper

A vibration damping device and vibration attenuation technology, which is applied in transmission devices, fluid transmission devices, springs/shock absorbers, etc., can solve the problems of expensive manufacturing and design, and achieve low friction, low spring coefficient, and small radial size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

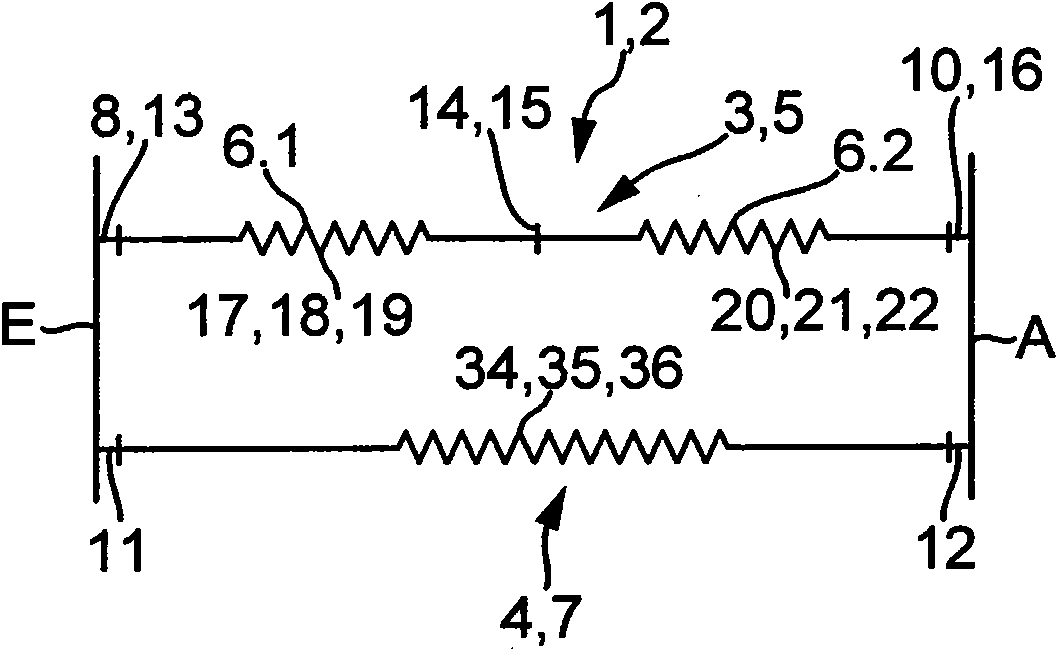

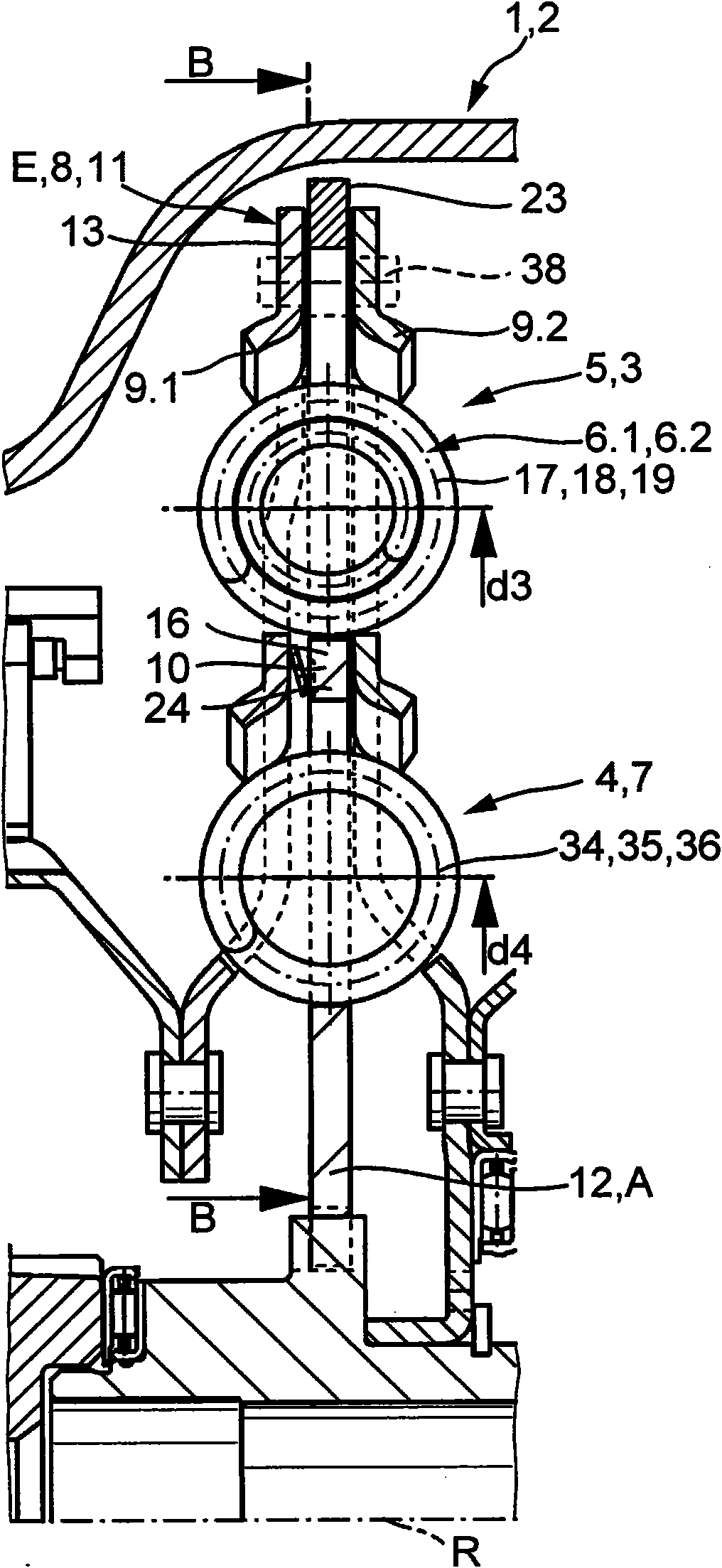

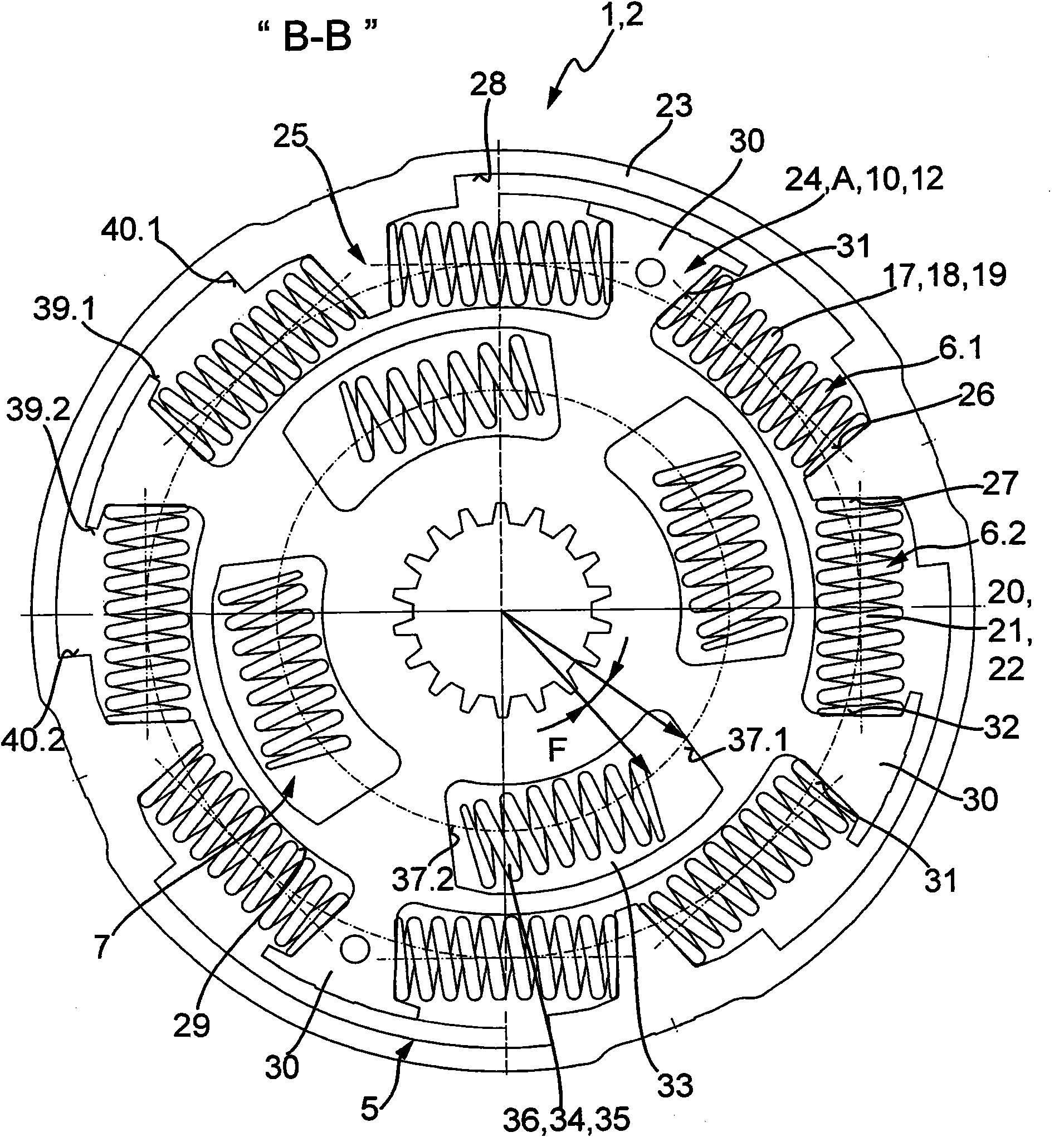

[0031] Figure 1a A device 1 for damping vibrations according to the invention, in particular in the form of a rotational vibration damper or torsional vibration damper, is shown in a schematic simplified illustration. The device according to the invention for damping vibrations is designed as a multi-stage series-parallel damper 2 . The device 1 for damping vibrations functionally comprises two damping stages 3 , 4 which are each formed from a damping device—a first damping device 5 and a second damping device 7—and are connected in parallel. Parallel connection here means that the damping devices 5 and 7 are arranged in parallel in the line of force. This line of force is realized in parallel or via the two damping devices 5 and 7 . In this case, according to the invention, the first damping device 5 is designed as a tandem damper, that is to say comprises at least two series-connected dampers 6.1 and 6.2. Series here means that the power transmission takes place in series...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com