Corn harvester

A harvester, corn technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of limited scope of application, unsuitable for corn harvesting operations, bulky and other problems, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

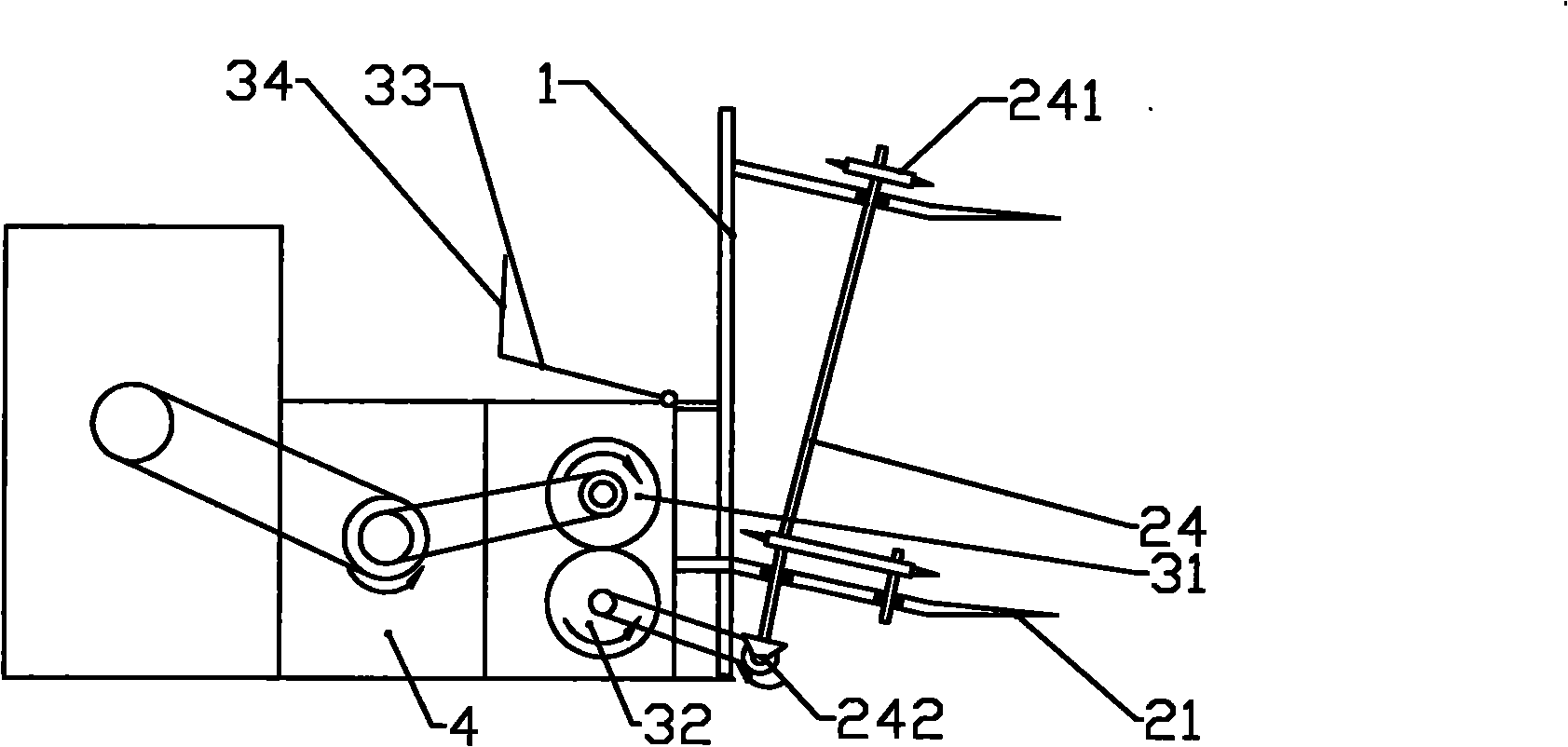

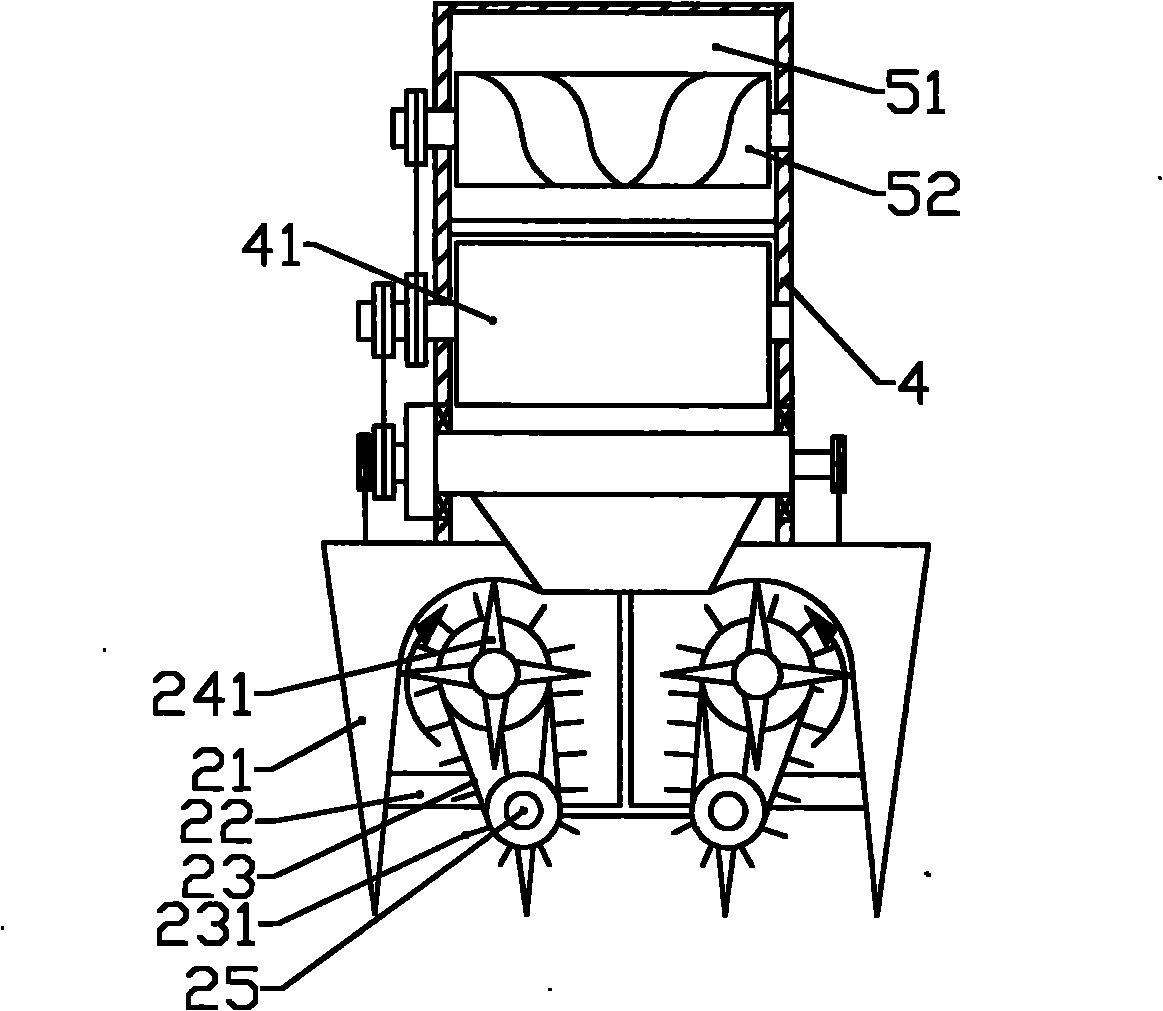

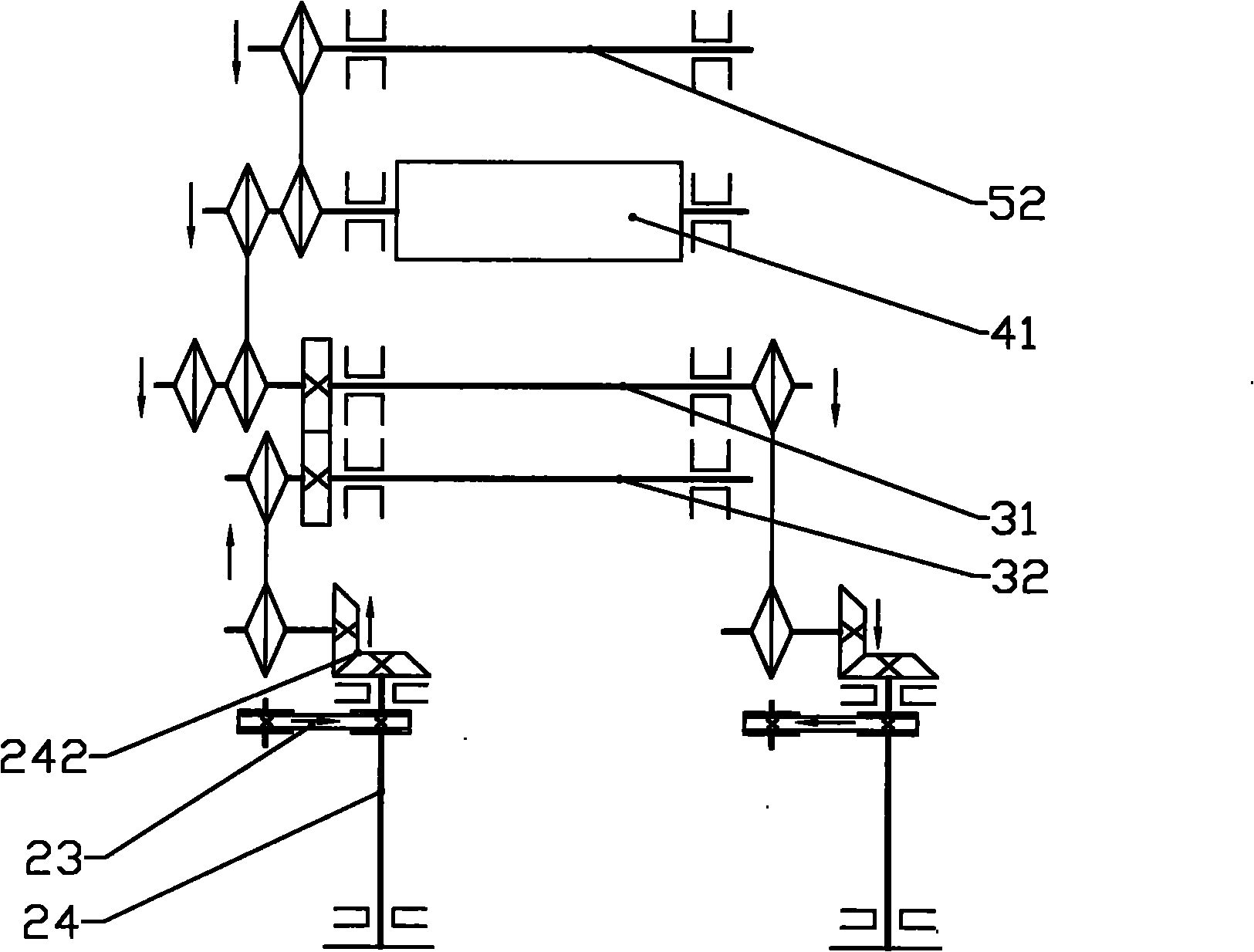

[0019] like Figure 1 ~ Figure 3 As shown, this kind of corn harvester includes: a frame, and a dredging and harvesting mechanism, a conveying mechanism, a crushing mechanism, and a chip removal mechanism installed on the frame from front to back.

[0020] Frame 1, the frame is installed in front of the tractor, and the whole frame is combined by welding to provide support for the installation of other components.

[0021] The dredging and harvesting mechanism, the dredging and harvesting mechanism is placed obliquely at the front end of the frame, with one left and right symmetrical piece, which can dredge two rows of corn at the same time, including a dredging device 21, a cutting tool 22, a toggle belt 23 and a transmission shaft 24 . Described dredger 21 is positioned at the front portion of frame 1, and opening is figure-eight, is convenient to collect corn stalk; Described cutting tool 22 is positioned at the bottom of frame 1 front end; Described transmission shaft 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com