Metal mould containing sandmold insert and application thereof in tilted casting

A technology of metal molds and inserts, which is applied to casting molding equipment, metal processing equipment, casting molds, etc., can solve problems such as difficulty in improving quality levels, increased energy consumption, increased costs, and increased load on tilting machines, so as to simplify mold design , long mold life and low loss of metal mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described through the following examples in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

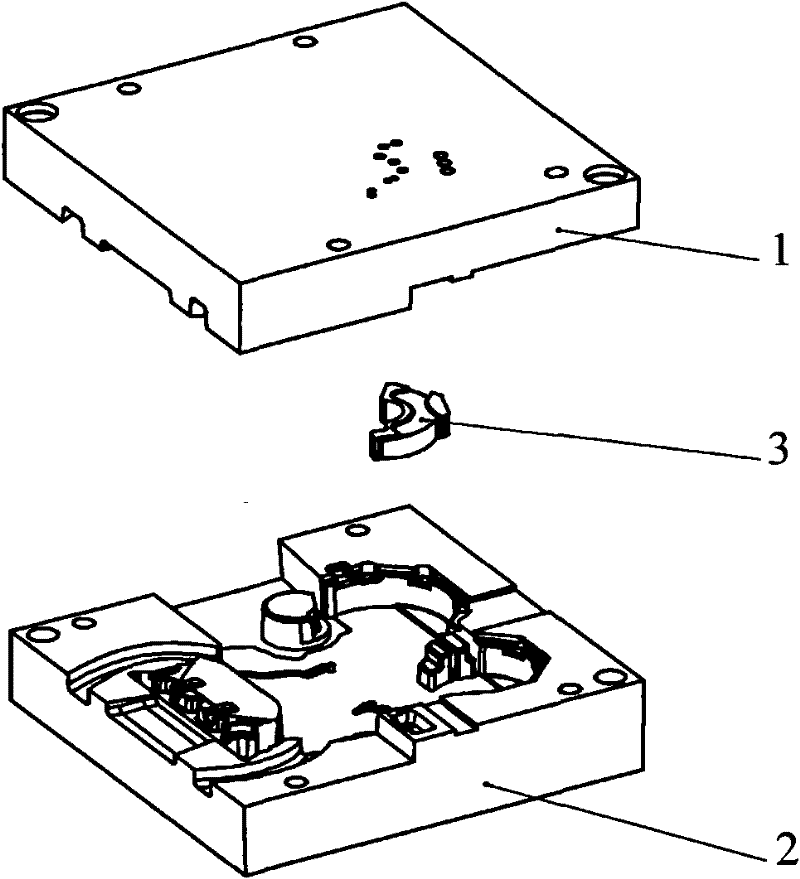

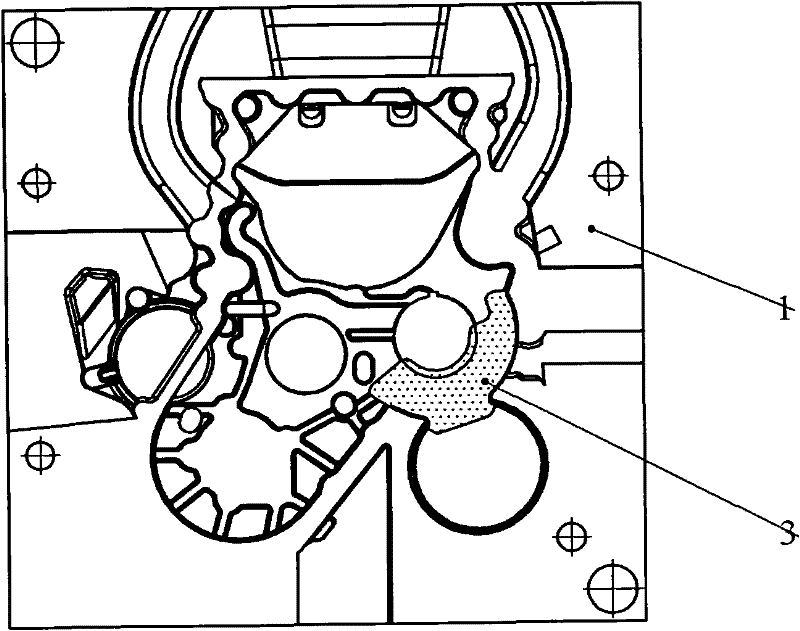

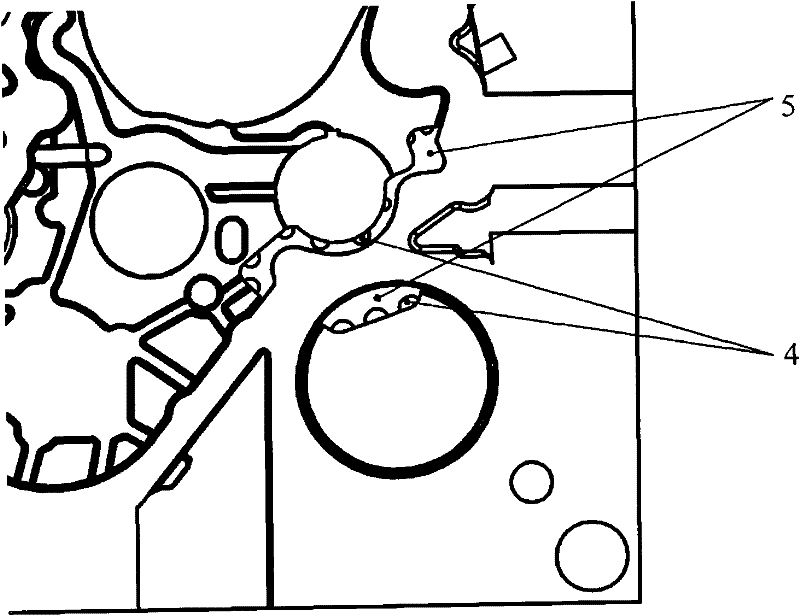

[0023] The structure of the metal mold containing sand inserts used in the production of castings in this embodiment mainly includes a metal upper mold 1, a metal lower mold 2, a sand mold insert 3, a metal mold vent 4, and an insert support seat 5. figure 1 and figure 2 The positional relationship between the sand mold insert 3 and the metal upper mold 1 and the metal lower mold 2 is given. Since there is a cavity in the casting blank 6, the sand mold insert 3 needs to be installed at the cavity position, and after process analysis, this position also produces air holes The position of the defect, so the sand mold insert 3 is not only used as the core, but also used to discharge the residual gas in the cavity; the shape of the sand mold insert 3 is determined by the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com