Automatic argon welding head

A technology of argon arc welding and machine head, which is applied in the direction of welding equipment, arc welding equipment, manufacturing tools, etc. It can solve the problems of unguaranteed welding quality, inability to achieve accurate positioning, cumbersome operation, etc., and achieves easier quality assurance, structure Compact and practical, simple compact and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

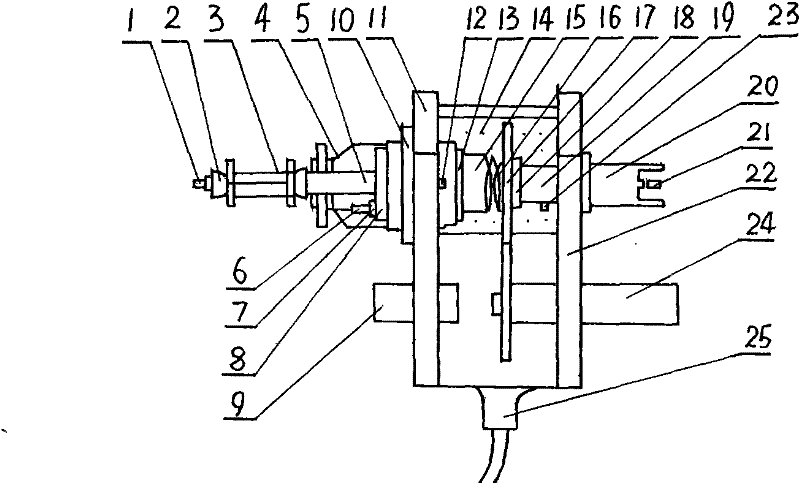

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

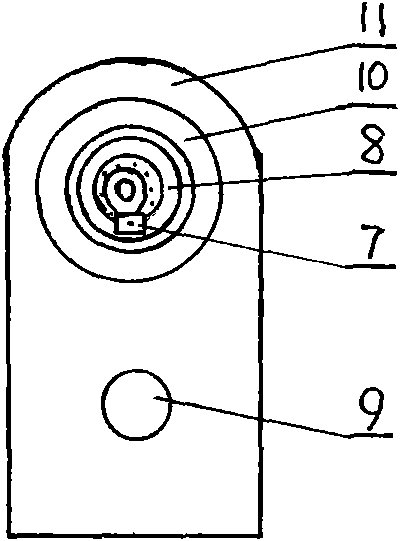

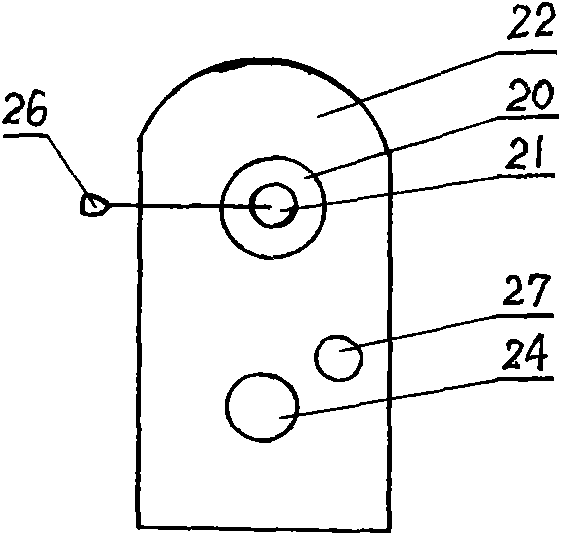

[0027] Such as figure 1 As shown, the welding torch system of the present invention includes a tungsten rod 6, a tungsten rod fixing plate 7, and a tungsten rod connecting plate 8, and the tungsten rod 6 is fixed on the tungsten rod connecting plate 8 through the tungsten rod fixing plate 7; Including airtight gas cover 4 made of metal, insulating sleeve 5 made of porcelain material, such as Figure 13 , 14 Shown, airtight gas cover 4 is metal material, and cover mouth is provided with porcelain sleeve 35, plays high temperature resistance, protection, insulation effect, and cover surface is provided with three adjustable jackscrews 36, to stabilize the machine head.

[0028] The support system of the present invention includes a left support frame 11 and a right support frame 22, and an electric ring seat 10, a cooling water inlet 12 and a water outlet are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com