Spherical hinge disc suspension type connection device of converter ring and furnace shell

A converter support ring and connecting device technology, applied in the direction of manufacturing converters, etc., can solve the problems of difficult installation and many connection points, and achieve the effects of simple structure, reliable connection, and avoidance of local overload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

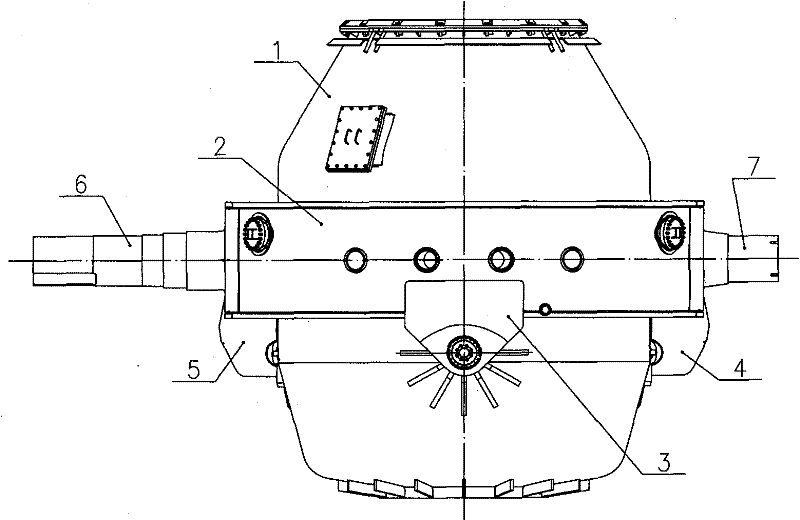

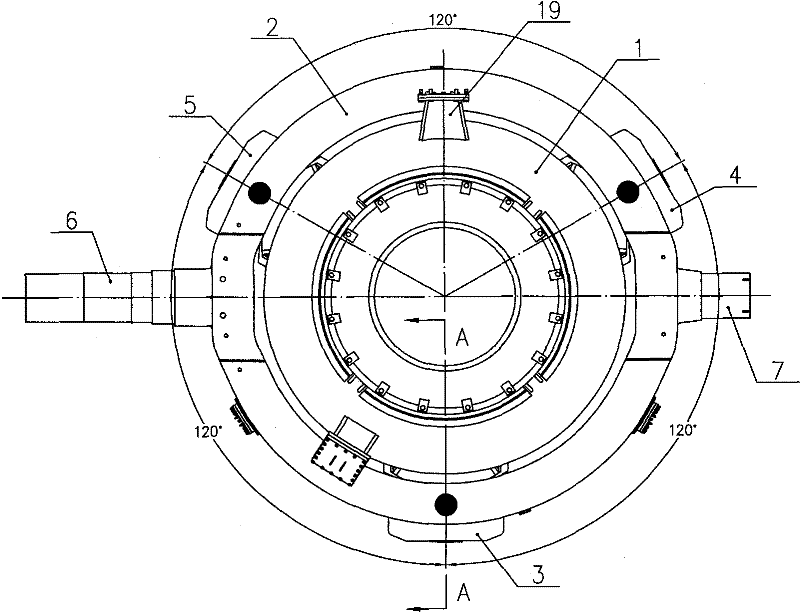

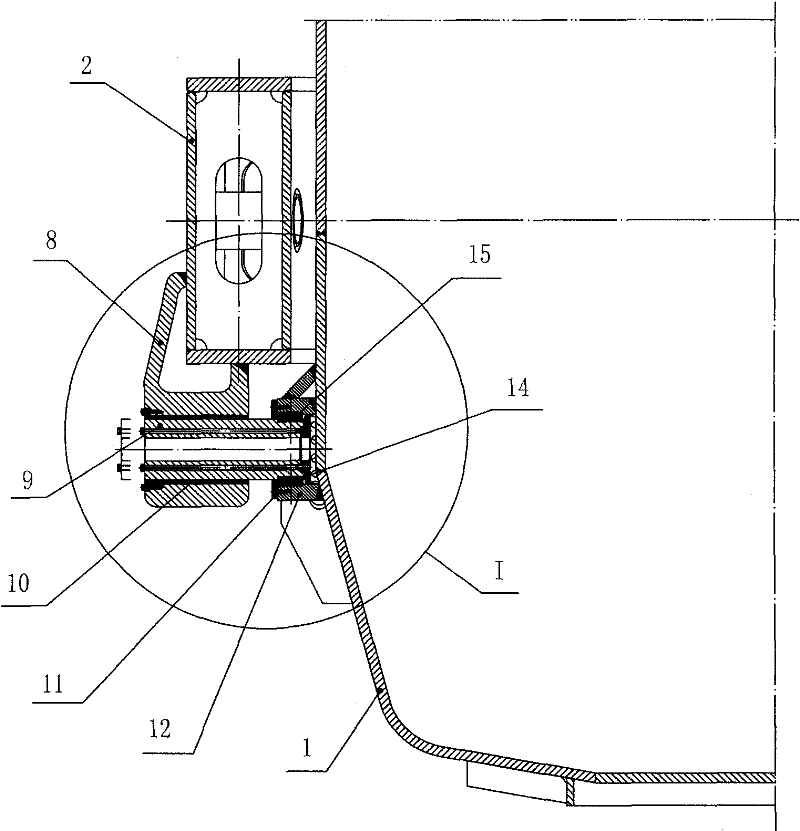

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the connecting device of the spherical hinge suspension disc type converter support ring and the furnace shell is composed of three connecting units (or called spherical hinge sliding rod mechanisms) (namely the first connecting unit 3, the second connecting unit 4, the second connecting unit Three connection units 5);

[0033] Each connection unit includes ear seat 8, support shaft 9, sliding sleeve 10, gland 11, support ring 12, rib plate 13, end cover 14, ball joint bearing 15, and ear seat 8 is fixedly connected with support ring 2 (such as welding ), the lug 8 is provided with a sliding sleeve through hole, the sliding sleeve 10 is located in the sliding sleeve through hole, the sliding sleeve 10 is fixedly connected with the lug 8 (such as connected by bolts), and the outer end of the support shaft 9 penetrates the sliding sleeve 10 (the support shaft 9 can slide along the a...

Embodiment 2

[0038] Such as Figure 7 As shown, there are four connecting units (namely the first connecting unit 3, the second connecting unit 4, the third connecting unit 5, and the fourth connecting unit 21), which are evenly distributed and form an angle of 90 degrees between them. The included angle between the line connecting the connecting unit and the center of the converter and the axis of the trunnion (the axis of the trunnion 6 at the transmission end and the axis of the supporting trunnion 7 ) is 25° to 45°. In the vertical direction of the furnace shell, the connection unit is arranged at the center of gravity of the furnace shell and refractory materials inside the furnace shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com