Oil-in-water powdery emulsion explosive, preparation method and application thereof

A technology of powdery emulsion explosives and oil-in-water type, which is applied to explosives processing equipment, explosives, offensive equipment, etc., and can solve the problems of large consumption of compressed air and dry air, high viscosity of water-in-oil type emulsions, and increased investment costs. , to achieve the effect of improving intrinsic safety, excellent caking resistance, and reducing the cost of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

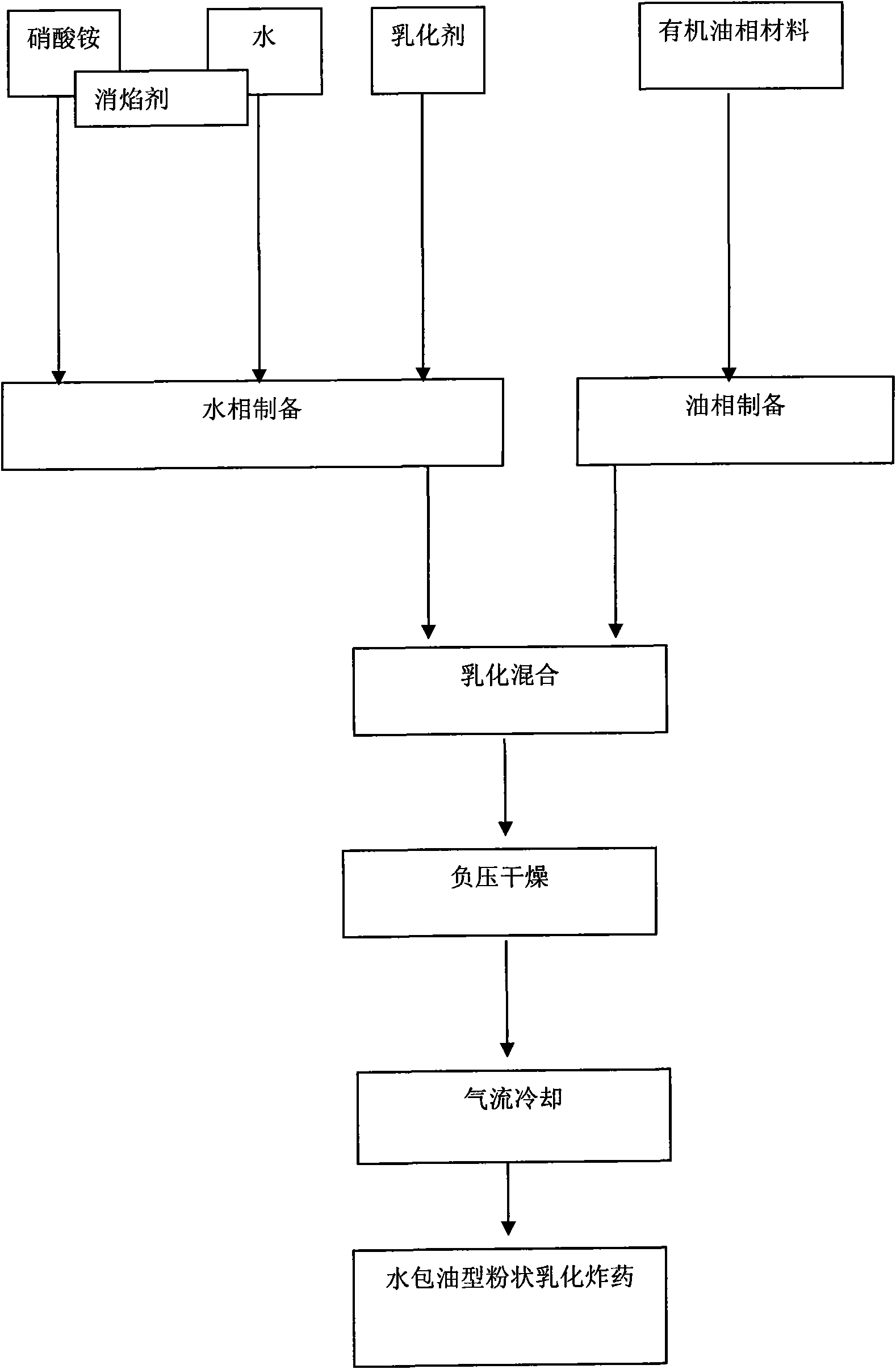

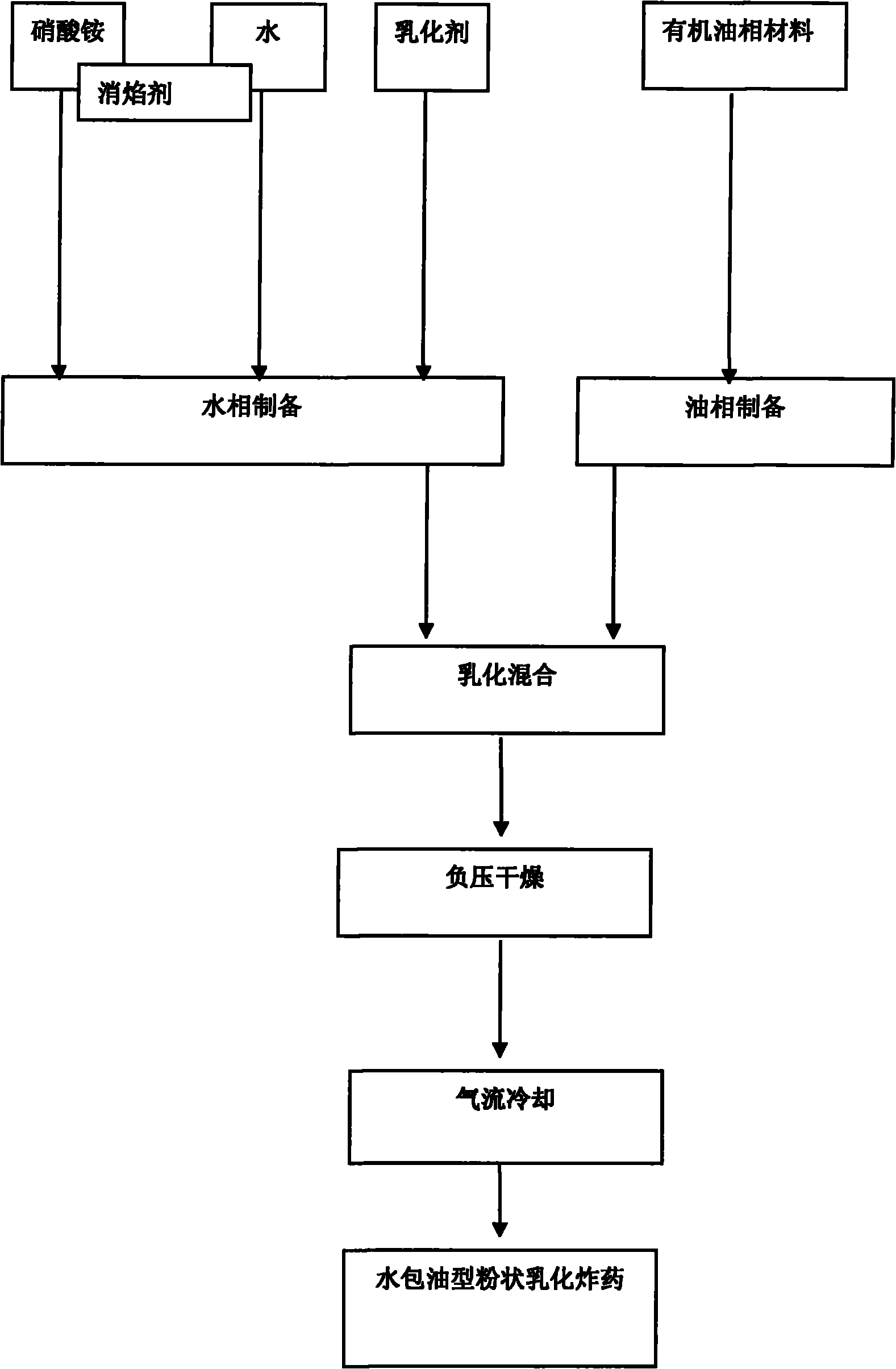

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Taking the preparation of 500 kg of oil-in-water powdery emulsion explosive as an example, the mass percentages of the selected components are: ammonium nitrate 87.6, emulsifier (surfactant BS-12) 0.01, water 7.99, composite wax 4.4 . Accurately weigh 438 kg of ammonium nitrate, 0.05 kg of emulsifier, 39.95 kg of water, and 22 kg of composite wax according to the above proportioning ratio.

[0017] Operation steps: the first step is to heat and dissolve ammonium nitrate, emulsifier and water and raise the temperature to 113°C; the second step is to heat and melt the composite wax and raise the temperature to 125°C; the third step is to mix the oxidant solution and combustible solution into a uniform The oil-in-water emulsion mixture; the fourth step is to dehydrate and dry the mixture obtained in the third step to form an oil-in-water powder emulsion explosive; the fifth step is to prepare the oil-in-water powder emulsion explosive in the fourth step After be...

Embodiment 2

[0018] Example 2 Taking the preparation of 500 kg of oil-in-water powdery emulsion explosive as an example, the mass percentages of each component are selected as: ammonium nitrate 81.9, emulsifier (ligninsulfonate quaternary ammonium salt) 0.1, water 12.6, composite wax 5.4. Accurately weigh 409.5 kg of ammonium nitrate, 0.5 kg of emulsifier, 63 kg of water, and 27 kg of composite wax according to the above proportioning ratio.

[0019] Operation steps: the first step is to heat and dissolve ammonium nitrate, emulsifier and water and raise the temperature to 100°C; the second step is to heat and melt the composite wax and raise the temperature to 105°C; the third step is to mix the oxidant solution and combustible solution The oil-in-water emulsion mixture; the fourth step is to dehydrate and dry the mixture obtained in the third step to form an oil-in-water powder emulsion explosive; the fifth step is to prepare the oil-in-water powder emulsion explosive in the fourth step ...

Embodiment 3

[0020] Example 3 Taking the preparation of 500 kilograms of oil-in-water powdery emulsion explosives as an example, the mass percentages of the selected components are: ammonium nitrate 81.9, emulsifier (surfactant BS-12) 0.3, water 12.6, composite wax 5.2 . Accurately weigh 409.5 kilograms of ammonium nitrate, 1.5 kilograms of emulsifier, 63 kilograms of water, and 26 kilograms of composite wax according to the above proportioning ratio.

[0021] Operation steps: the first step is to heat and dissolve ammonium nitrate, emulsifier and water and raise the temperature to 100°C; the second step is to heat and melt the composite wax and raise the temperature to 105°C; the third step is to mix the oxidant solution and combustible solution The oil-in-water emulsion mixture; the fourth step is to dehydrate and dry the mixture obtained in the third step to form an oil-in-water powder emulsion explosive; the fifth step is to prepare the oil-in-water powder emulsion explosive in the fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Detonation velocity | aaaaa | aaaaa |

| Fierceness | aaaaa | aaaaa |

| Work ability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com