Microchannel enhanced heat exchange system of rotary room-temperature magnetic refrigerator and heat transfer method thereof

A room-temperature magnetic refrigerator and enhanced heat transfer technology, applied in refrigerators, refrigeration and liquefaction, machines using electric/magnetic effects, etc., can solve the problem of large heat transfer resistance and complex heat transfer methods for solid working fluids and heat transfer fluids , low cycle heat transfer efficiency and other issues, to achieve the effect of ensuring safe and effective operation, obvious heat transfer effect, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following describes the present invention in further detail with reference to the drawings and implementation examples, but the embodiments of the present invention are not limited thereto.

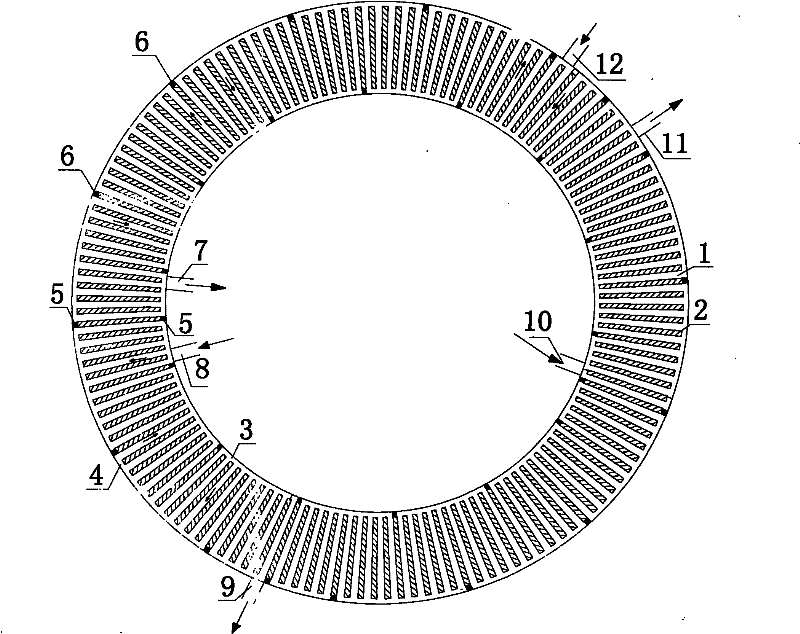

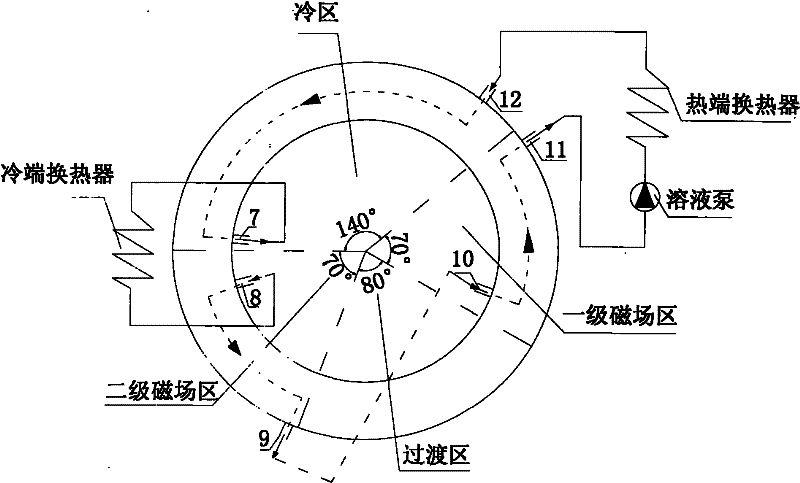

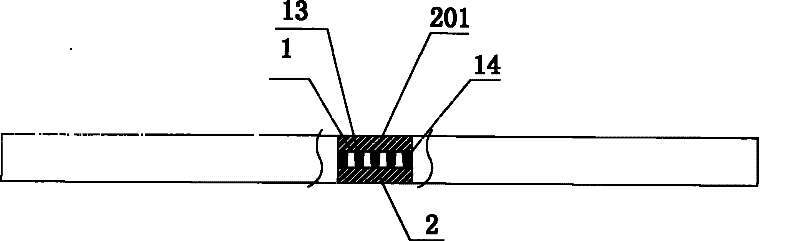

[0019] Such as figure 1 with image 3 As shown, the microchannel enhanced heat exchange system of the rotary room temperature magnetic refrigerator includes a layer of trapezoidal microchannel flat tubes 1, two layers of magnetic working medium plates 2 ( figure 1 The middle 2 is the lower magnetic working medium plate), the inner ring liquid collecting tank 3, the outer ring liquid collecting groove 4, four pairs of interval insulating baffles 5, multiple zone insulating baffles 6, etc. It consists of connected cold end heat exchanger, hot end heat exchanger and solution pump. The upper magnetic working medium plate 201 and the lower magnetic working medium plate 2 are processed into circular thin plates, and the trapezoidal micro-channel flat tube 1 in the middle layer is process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com