Automatic weight loading system of piston type gauge

A piston-type pressure gauge and automatic loading technology, which is applied in the direction of piston-type fluid pressure measurement, fluid pressure measurement, and measurement devices, can solve the problems of relying on manual adjustment control difficulty, unstable measurement status, etc., to simplify the measurement work , prolong the service life and improve the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, further illustrate the present invention.

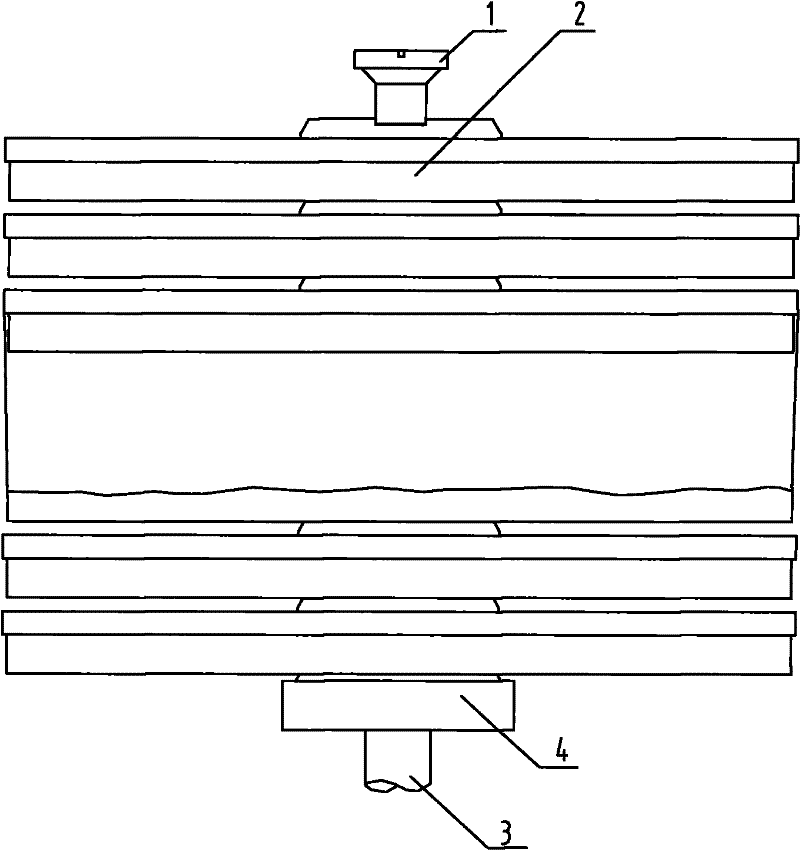

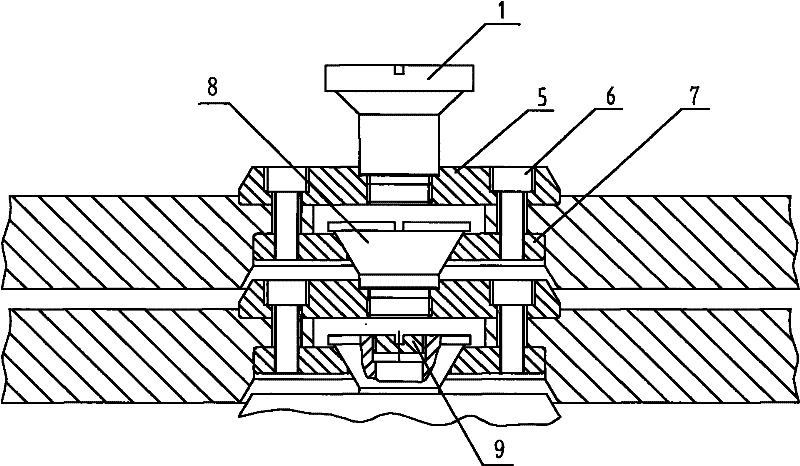

[0025] A program-controlled automatic weight loading system has been successfully developed on the above-mentioned ultra-high pressure piston pressure gauge.

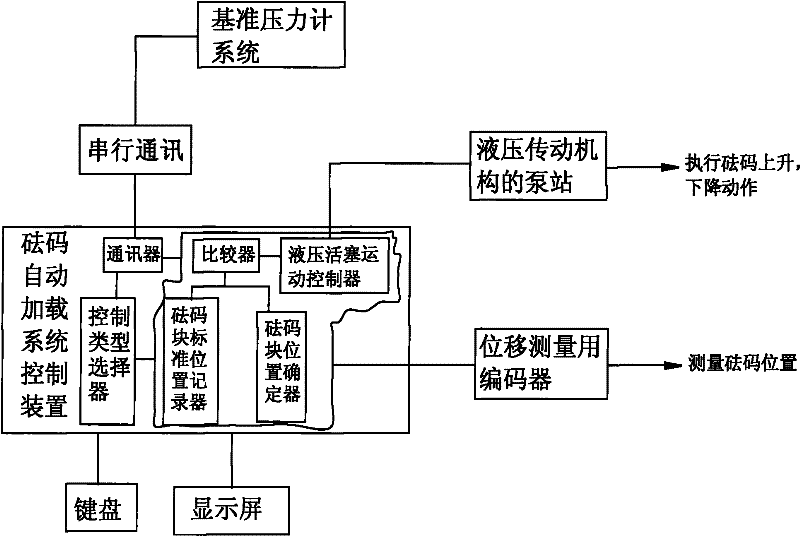

[0026] The whole system converts the vertical displacement of the weight into an angle change through a displacement measuring device including a displacement-angle conversion mechanism, and uses encoder measurement to generate a pulse output corresponding to the position change of the weight. Using MCS51 single-chip microcomputer technology, this output The pulse is converted into the actual displacement of the weight. According to the program requirements, the motor and the solenoid valve are driven to control the lifting of the hydraulic piston so as to control the lifting of the weight so that it reaches the actual required position. RS232 communication technology and reference pressure gauge measurement and control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com