Light guide module of optical fingerprint identification system

A fingerprint identification and light guide module technology, which is applied in the light guide, light guide, optics and other directions of the lighting system, can solve the problems of difficult assembly, high assembly cost, and uneconomic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

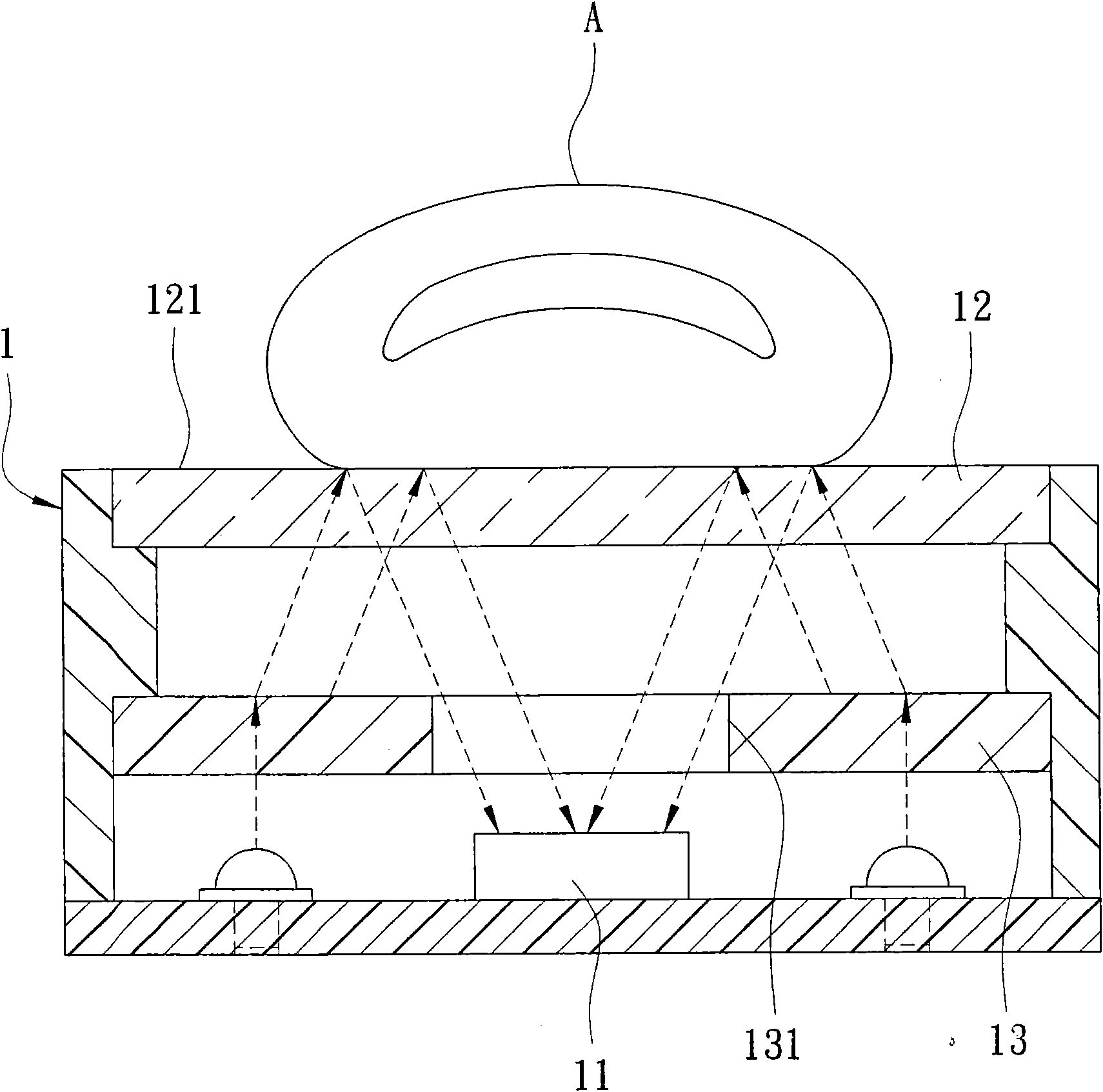

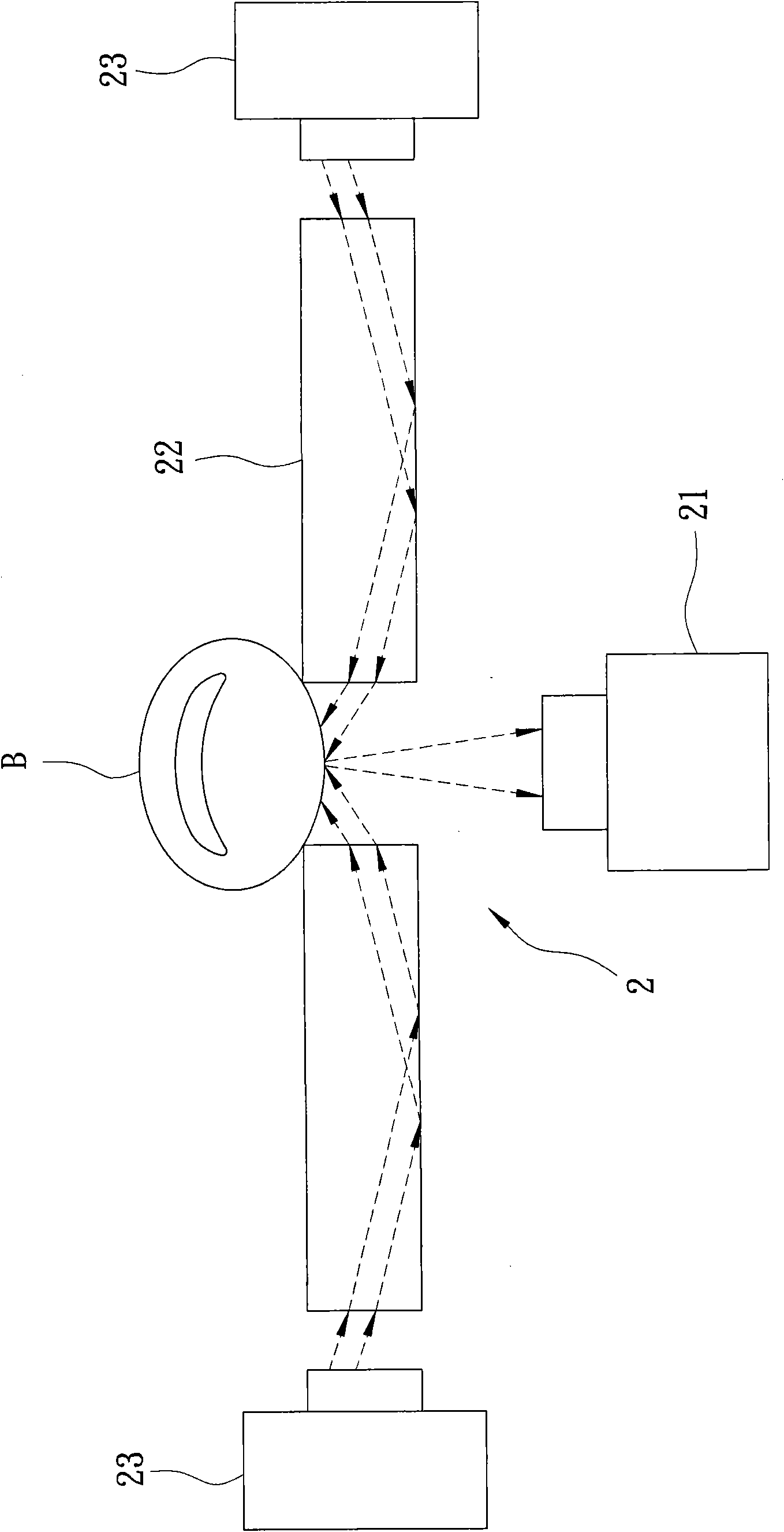

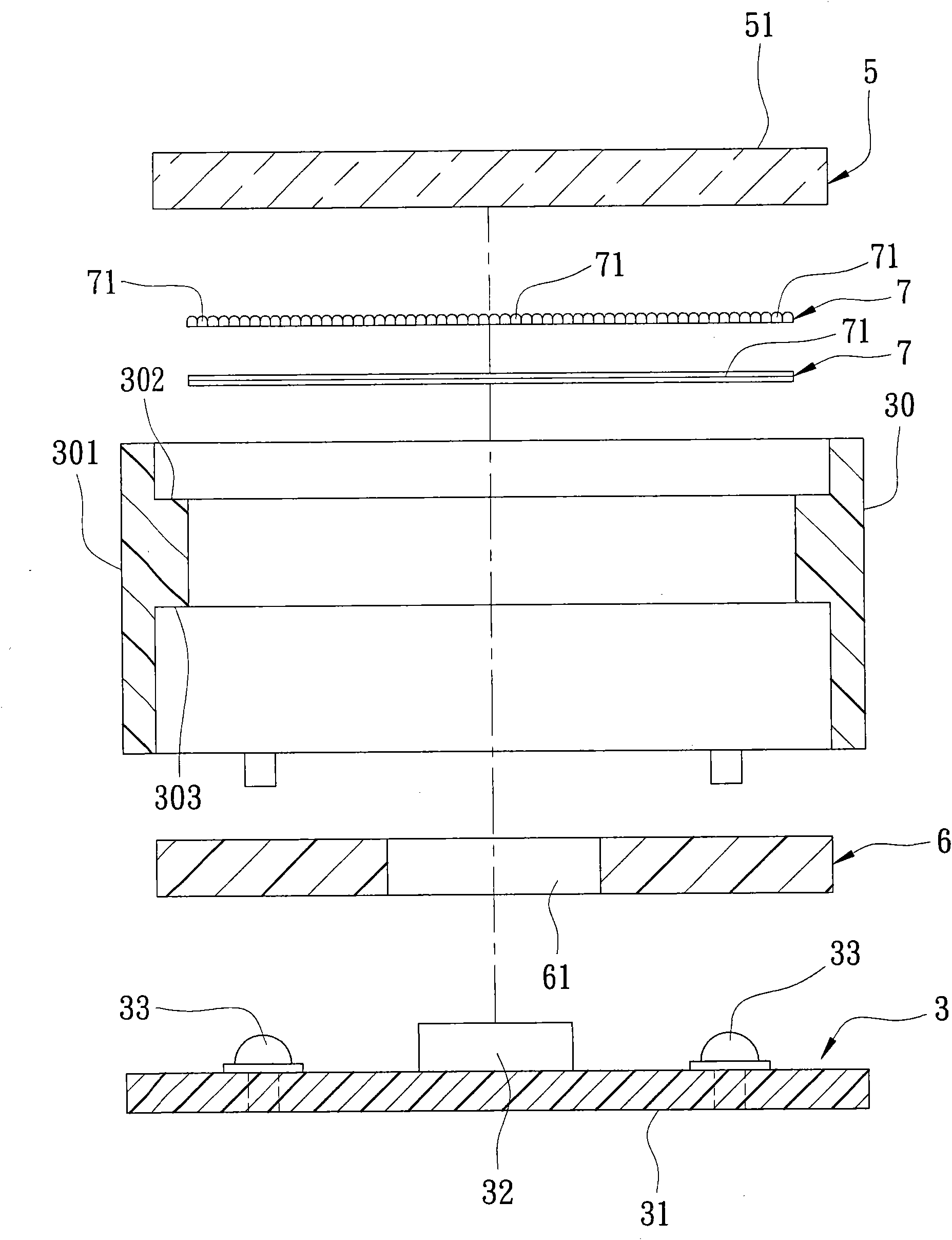

[0016] refer to image 3 ,and Figure 4 A first preferred embodiment of the light guide module of the optical fingerprint identification system of the present invention is installed in a fingerprint identification system 3 . The fingerprint recognition system 3 has a housing 30 , a circuit board 31 combined with the housing 30 , an imaging device 32 arranged on the circuit board 31 , and several light sources 33 for emitting light. The casing 30 has a ring wall 301 surrounding the imaging device 32 and the light source 33 , and a first step edge 302 and a second step edge 303 formed on an inner surface of the ring wall 301 . The aforementioned light sources 33 are respectively an LED lamp. The light guide module includes a pressing plate 5 , a light diffusing plate 6 , and two microstructure layers 7 .

[0017] In this preferred embodiment, the pressing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com