Fruit and vegetable anti-bacterial refreshing permeable film and manufacturing method thereof

A manufacturing method and a technology of a breathable film, which are applied in the fields of fruit and vegetable preservation, chemical instruments and methods, food preservation, etc., can solve the problems of short preservation time and poor preservation effect, and achieve the effects of simple method, environmental protection and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

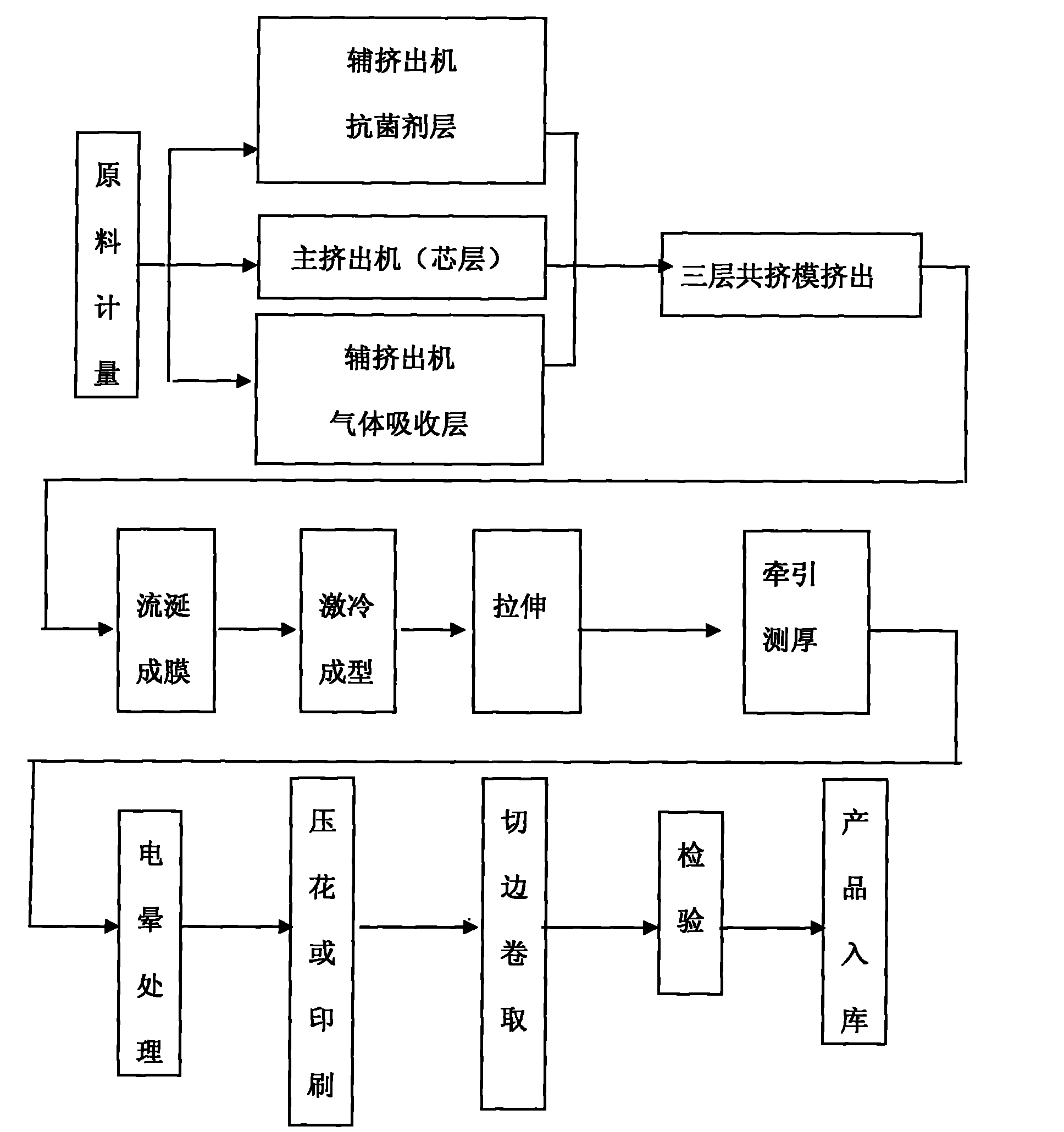

Method used

Image

Examples

Embodiment 1

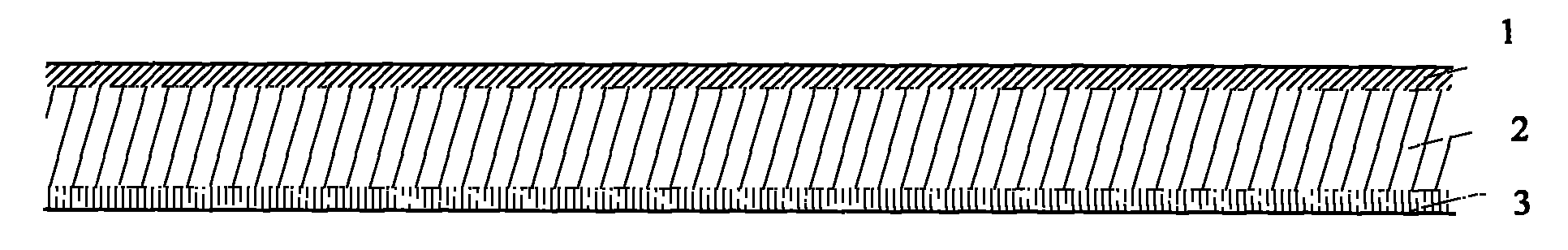

[0029] refer to figure 1 , an antibacterial fresh-keeping breathable film for fruits and vegetables, comprising an upper layer 1, a middle layer 2 and a lower layer 3, the upper layer 1 is an antibacterial agent layer, the middle layer 2 is a core layer, and the lower layer 3 is a gas absorption layer, the The middle layer 2 is covered on the lower layer 3, the upper layer 1 is covered on the middle layer 2, and the mass percentage of the antibacterial agent layer, core layer and gas absorption layer in the total mass is: antibacterial agent layer: 15 ~20%; core layer: 60~70%; gas absorption layer: 15~20%;

[0030] The antibacterial agent layer includes metallocene polyethylene, linear low density polyethylene, active calcium carbonate masterbatch, stabilizer, antioxidant and antibacterial agent, and the mass-number ratio of various components is: metallocene polyethylene 24~ 30 parts; 6-10 parts of linear low-density polyethylene; 7-13 parts of active calcium carbonate maste...

Embodiment 2

[0058] refer to figure 1 , In this embodiment, the mass percentages of the total mass of the antibacterial agent layer, core layer and gas-absorbing layer are: antibacterial agent layer: 16%; core layer: 66%; gas-absorbing layer: 18%.

[0059] In the antibacterial agent layer, the ratio of parts by mass of the components is: 25 parts of metallocene polyethylene; 7 parts of linear low density polyethylene; 8 parts of active calcium carbonate masterbatch; 0.2 part of stabilizer; 0.15 part of antioxidant ; 0.2 part of antibacterial agent;

[0060] In the core layer, the mass-number ratio of the components is: 45 parts of metallocene polyethylene; 10 parts of linear low-density polyethylene; 30 parts of active calcium carbonate masterbatch; 1.0 part of stabilizer; 0.3 part of antioxidant;

[0061] In the gas-absorbing layer, the mass-number ratio of various components is: 25 parts of metallocene polyethylene; 8 parts of linear low-density polyethylene; 8 parts of active calcium c...

Embodiment 3

[0064] refer to figure 1 , In this embodiment, the mass percentages of the total mass of the antibacterial agent layer, core layer and gas-absorbing layer are: antibacterial agent layer: 15%; core layer: 70%; gas-absorbing layer: 15%.

[0065] In the antibacterial agent layer, the ratio of parts by mass of various components is: 26 parts of metallocene polyethylene; 8 parts of linear low density polyethylene; 10 parts of active calcium carbonate masterbatch; 0.22 parts of stabilizer; 0.21 parts of antioxidant part; 0.25 part of antibacterial agent;

[0066] In the core layer, the mass-number ratio of various components is: 48 parts of metallocene polyethylene; 11 parts of linear low-density polyethylene; 32 parts of active calcium carbonate masterbatch; 1.5 parts of stabilizer; 0.4 part of antioxidant ;

[0067] In the gas-absorbing layer, the mass-to-number ratios of various components are: 25 parts of metallocene polyethylene; 8 parts of linear low-density polyethylene; 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com