High-Curie-point lead-free PTCR (Positive Temperature Coefficient of Resistance) thermo-sensitive ceramic material

A heat-sensitive ceramic with a high Curie point technology, applied in the field of PTCR heat-sensitive ceramic materials, can solve the problems of few reports on heat-sensitive ceramic temperature control materials, and achieve the effect of avoiding the harm of the environment and human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This example presses molecular formula (Bi 1 / 2 K 1 / 2-a / 2 Na a / 2 ) Ce 1-b D. b o 3 +cM for batching, where a=0, b=0.003. The initial raw material is selected from Bi 2 o 3 、K 2 CO 3 , CeO 2 , Sb 2 o 3 . Materials were prepared according to the following experimental process steps:

[0020] ①Press the initial raw material to Bi 0.5 K 0.5 Ce0.997 Sb 0.003 o 3 Formula ingredients, weighing 72.07g Bi 2 o 3 , 21.36g K 2 CO 3 , 106.38g CeO 2 , 0.275g Sb 2 o 3 ;

[0021] ②Weigh the Bi weighed in the previous step 2 o 3 、K 2 CO 3 , CeO 2 and Sb 2 o 3 Put it into the ball mill jar, and add appropriate distilled water and ball mill mixture for 4 hours;

[0022] ③Place the mixed slurry prepared in the previous step in a glass vessel and put it into an oven to heat and dry;

[0023] ④Calcinate the powder obtained in the previous step at a temperature of 800°C and keep it warm for 2 hours;

[0024] ⑤ The powder synthesized in the previous step is gra...

Embodiment 2

[0030] This example presses molecular formula (Bi 1 / 2 K 1 / 2-a / 2 Na a / 2 ) Ce 1-b D. b o 3 +cM for batching, where a=1, b=0.0026. The initial raw material is selected from Bi 2 o 3 、Na 2 CO 3 , CeO 2 , Sb 2 o 3 . Materials were prepared according to the following experimental process steps:

[0031] ①Press the initial raw material to Bi 0.5 Na 0.5 Ce 0.9974 Sb 0.0026 o 3 Formula ingredients, weighing 73.91g Bi 2 o 3 , 16.79g Na 2 CO 3 , 109.09g CeO 2 , 0.277g Sb 2 o 3 ;

[0032] ②The preparation process is the same as the steps ②~⑧ in Example 1.

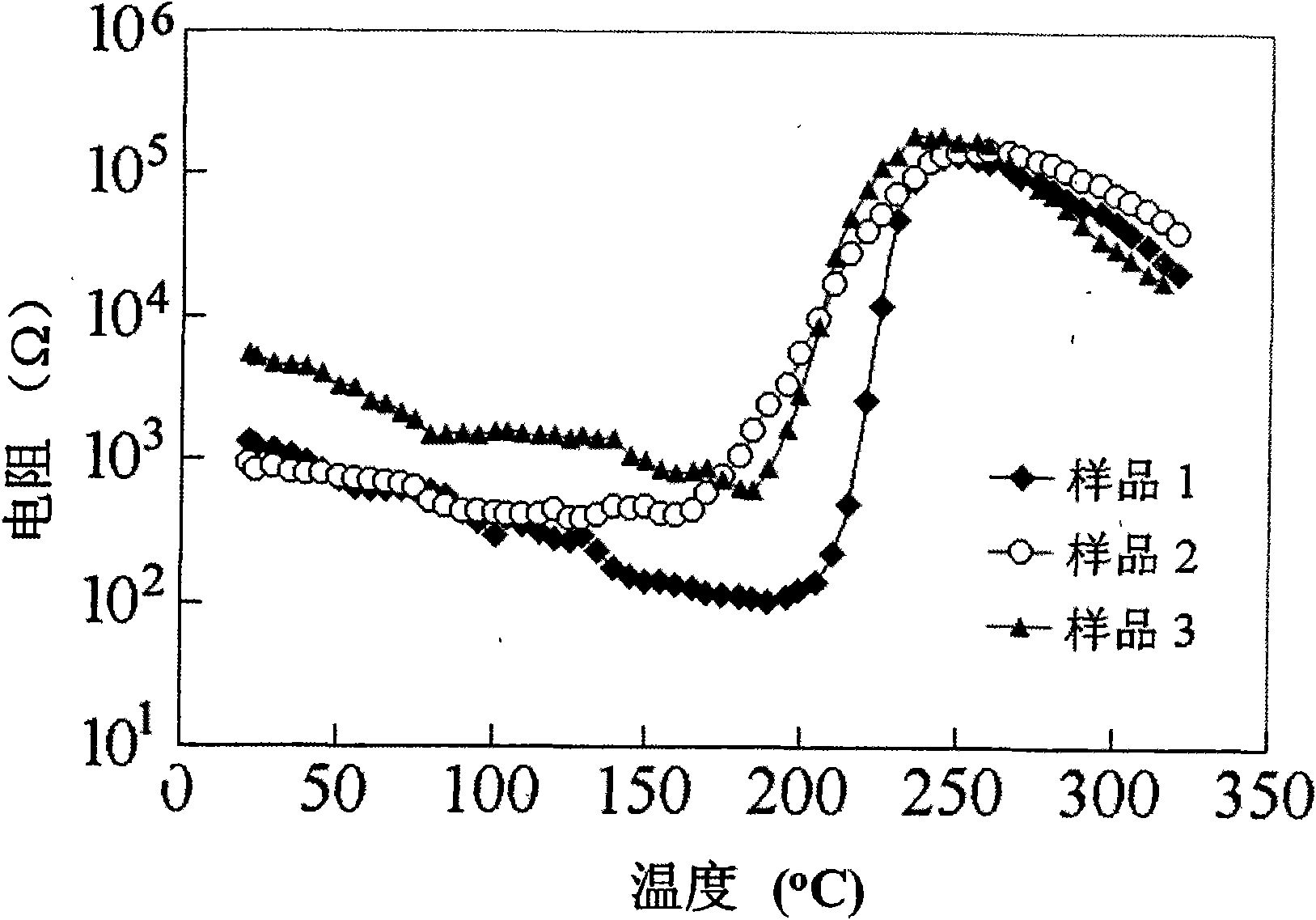

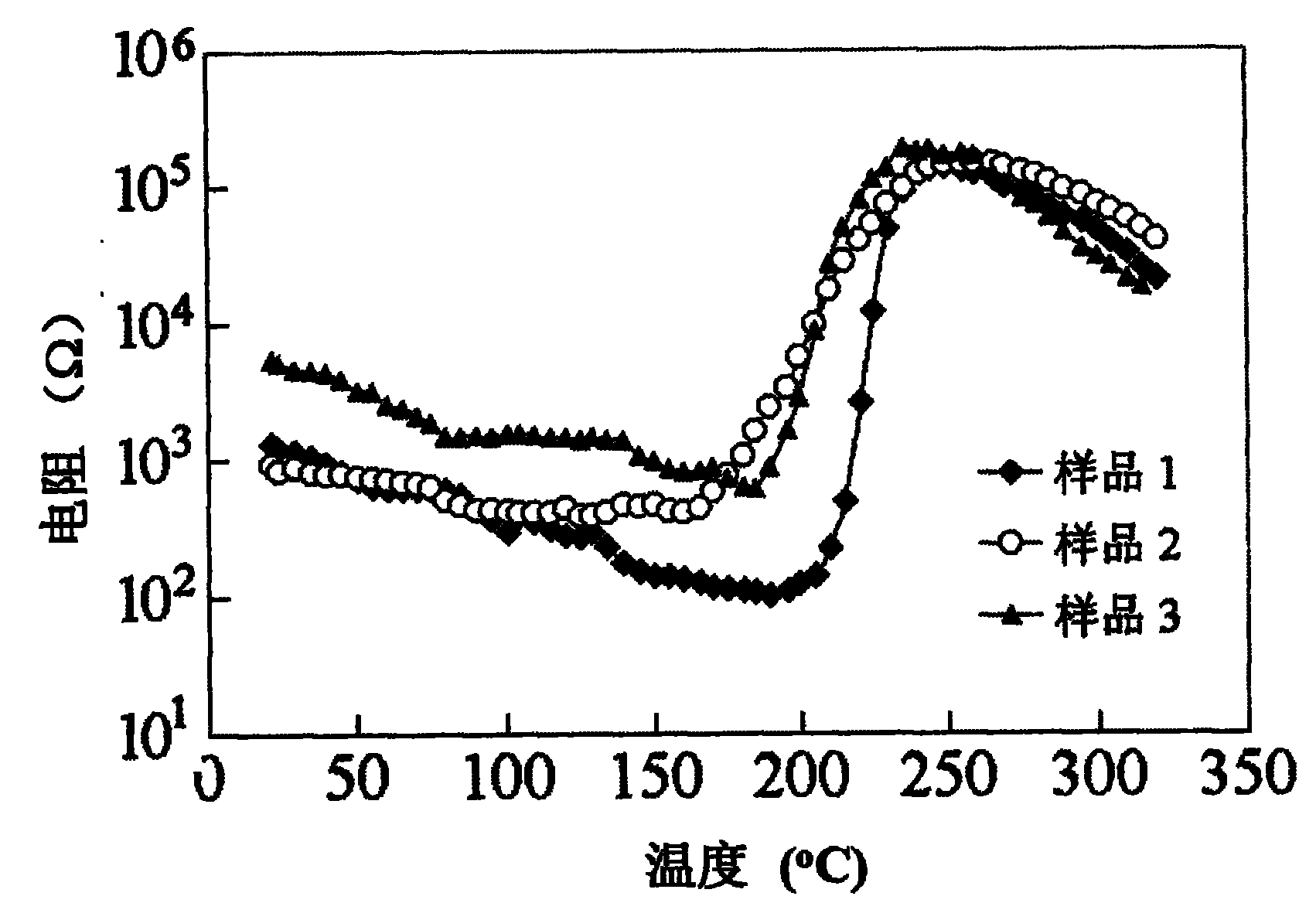

[0033] Prepared material properties are shown in Table 1 and figure 1 shown.

Embodiment 3

[0035] This example presses molecular formula (Bi 1 / 2 K 1 / 2-a / 2 Na a / 2 ) Ce 1-b D. b o 3 +cM for batching, where a=0.4, b=0.003. The initial raw material is selected from Bi 2 o 3 、K 2 CO 3 、Na 2 CO 3 , CeO 2 , Sb 2 o 3 . Materials were prepared according to the following experimental process steps:

[0036] ①Press the initial raw material to Bi 0.5 K 0.3 Na 0.5 Ce 0.997 Sb 0.003 o 3 Formula ingredients, weighing 36.54g Bi 2 o 3 , 6.5g K 2 CO 3 , 3.31g Na 2 CO 3 , 53.72g CeO 2 , 0.136g Sb 2 o 3 ;

[0037] ②The preparation process is the same as the steps ②~⑧ in Example 1.

[0038] Prepared material properties are shown in Table 1 and figure 1 shown.

[0039] Table 1 embodiment material performance index

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com