Spherical potassium chloride particle and preparation method thereof

A production method and potassium chloride technology are applied in the directions of alkali metal chlorides, potash fertilizers, inorganic fertilizers, etc., and can solve the problems of irregular large particles with polygonal appearance, unfavorable uniform absorption of crops, easy generation of damage and powder, etc. The effect of mechanical fertilization is good in layers, improves the feeding fluency, and is beneficial to storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The purpose of this example is to change the traditional granulation production method of potassium chloride, and change the irregular particles into spherical materials with smooth surface and high hardness, so as to make it a fertilizer with good slow-release effect, so as to facilitate more effective absorption by crops .

[0033] A kind of potassium chloride spherical particle of the present embodiment, it comprises the spherical particle that is made with potassium chloride powder potassium as main raw material as matrix, and described matrix appearance is white or red, and its surface particle is round, uniform, High hardness, its hardness is far better than irregular potassium chloride particles, the average hardness can reach 15-20 Newtons; its mechanical application level is good, which is conducive to storage, handling and transportation.

[0034] In the present embodiment, the diameter of the matrix is 2.5mm-5.5mm, and the elements in the matrix also includ...

Embodiment 2

[0036] In the present embodiment, the matrix is red or white fine crystals, which include sodium chloride, moisture, calcium, magnesium and sulfate radical matrix, by weight percentage, in the matrix: potassium chloride is 96.0%, moisture is 2% , Sodium chloride is 2.0%, calcium is 0.3%, magnesium is 0.2%, and sulfate is 0.72%.

[0037] Undescribed parts are the same as the examples.

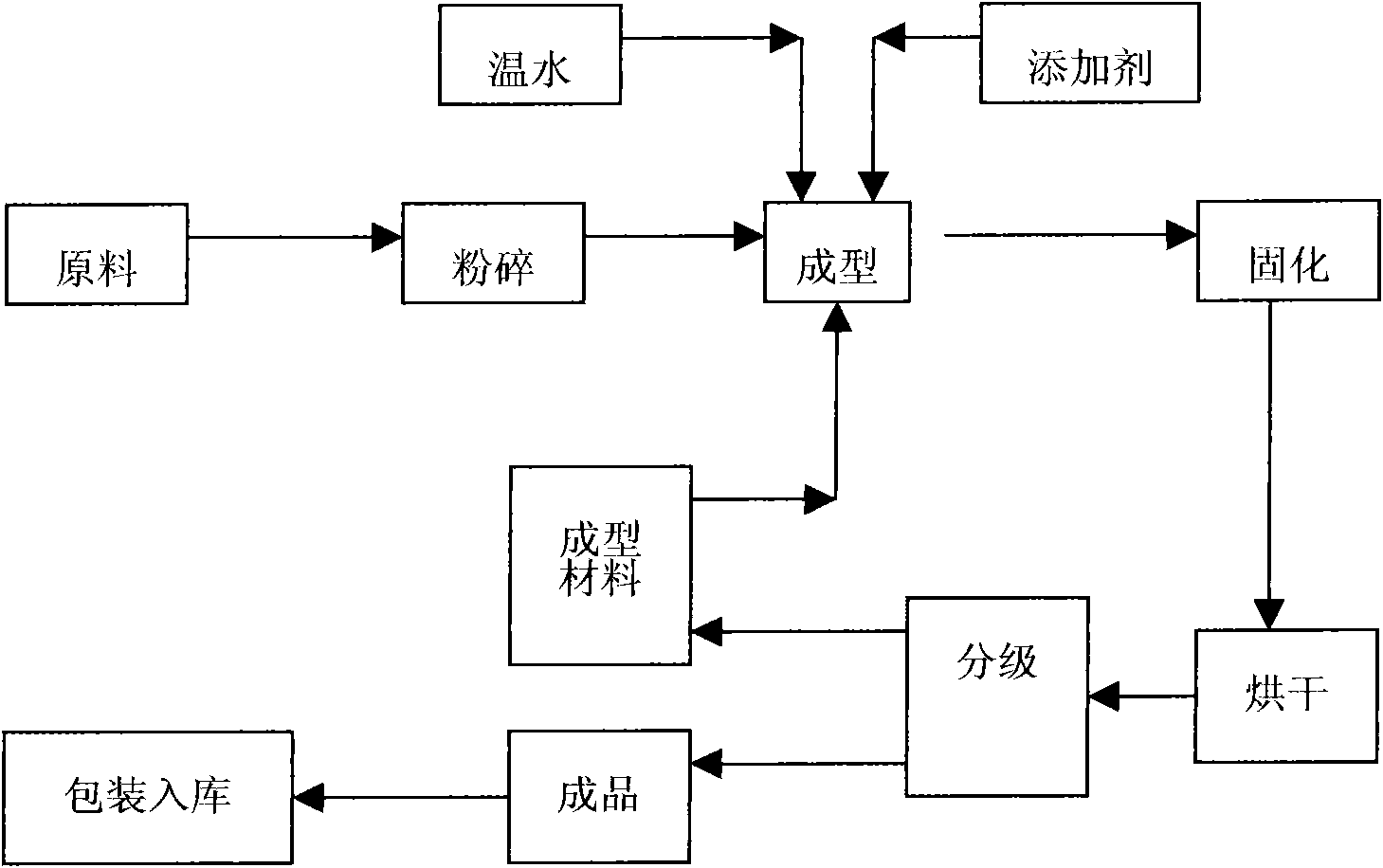

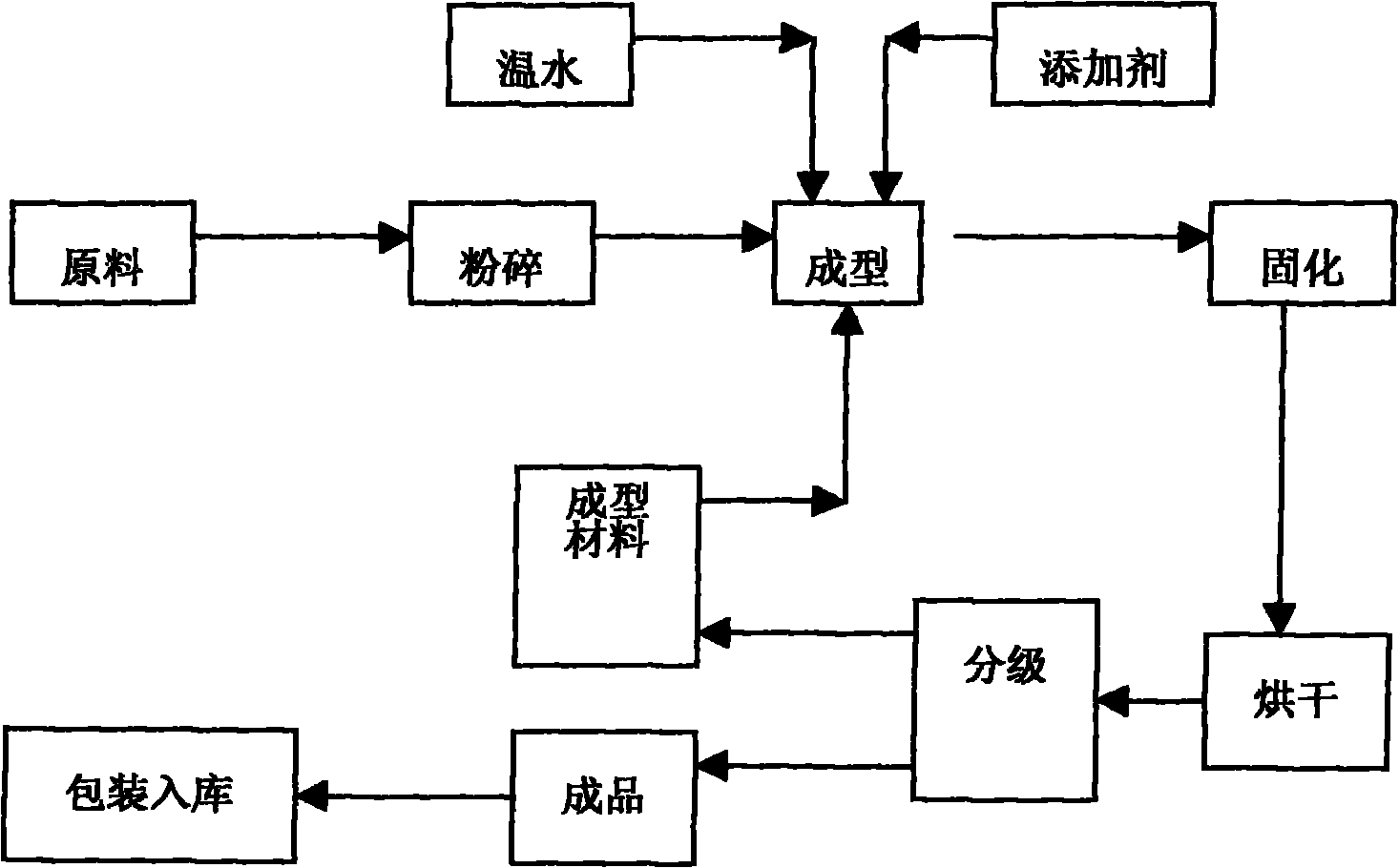

[0038] see figure 1 , above-mentioned two embodiment manufacturing methods, its method steps are as follows:

[0039] (1) raw material configuration; will be 98.0% by potassium chloride, sodium chloride is 1.2%, calcium is 0.1%, magnesium is 0.05%, sulfate radical is 0.25%, moisture is 2%; Or potassium chloride is 96.0 %, water content is 2%, sodium chloride is 2.0%, calcium is 0.3%, magnesium is 0.2%, and sulfate radical is the proportioning of 0.72% to carry out potassium chloride raw material configuration.

[0040] (2) Grinding and grinding; send the prepared potassium chloride raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap