Rotary flexible shaft supporting tube with support blades having inclined triangular-arc sections

A technology of oblique triangles and support tubes, applied in the direction of flexible shafts, shafts, shafts and bearings, etc., can solve the problems of reduced operating comfort, increased noise, and noise pollution, so as to improve operating comfort, prevent follow-up phenomenon, reduce Effects of Noise Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

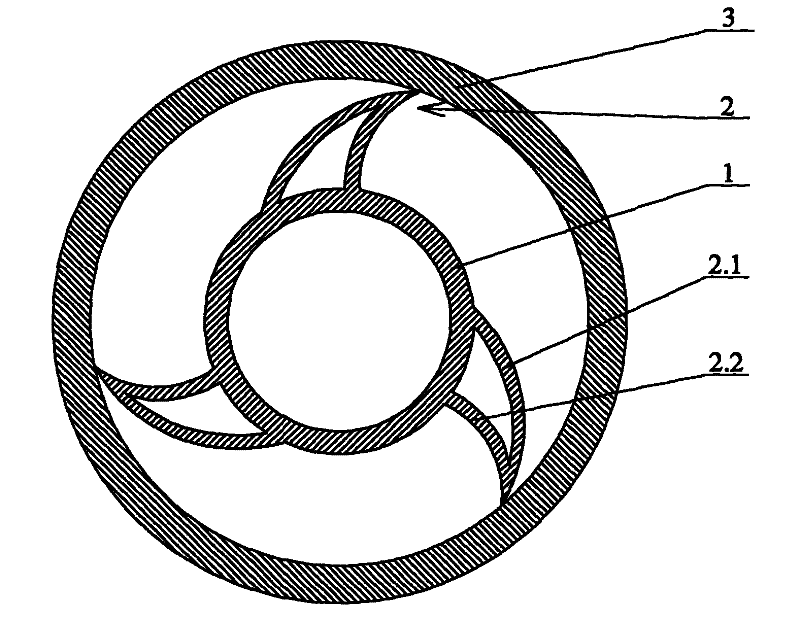

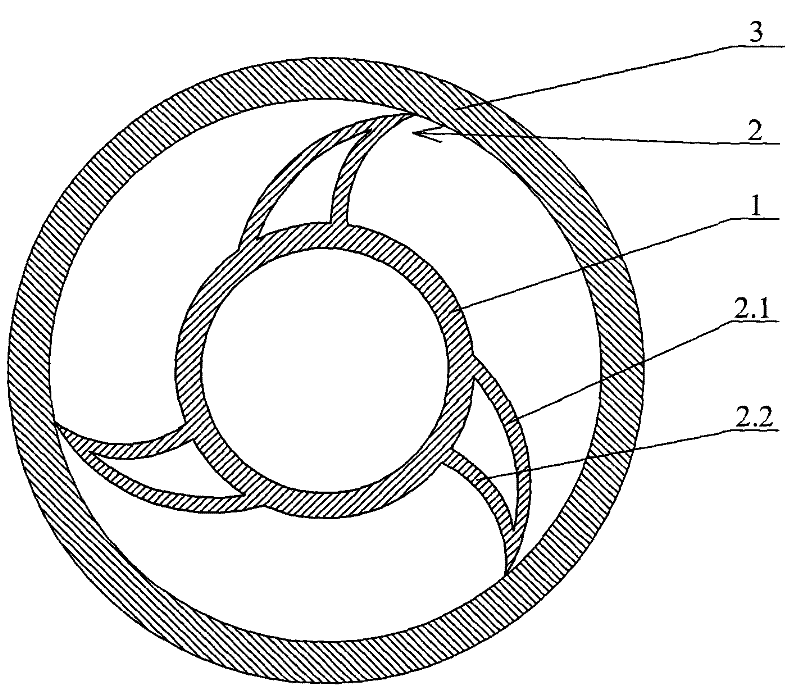

[0013] The rotating flexible shaft support tube with oblique triangular arc-shaped supporting blades in section includes three or more supporting blades 2 integrally arranged on the inner tube body 1 and the outer wall surface of the inner tube body 1, and the supporting blades 2 are inside The outer wall surface of the tube body 1 extends along the length direction of the inner tube body 1, the top end of the support blade 2 is clamped, the bottom end of the support blade 2 is stretched out, and the support blade 2 is composed of the first blade monomer 2.1 and the second blade The monomers 2.2 are formed by connecting the top parts, the bottom ends of the first blade monomer 2.1 and the second blade monomer 2.2 are connected with the outer wall of the inner tube body 1, and the first blade monomer 2.1 and the second blade monomer 2.2 The sections are all arc-shaped, the wall thicknesses of the first blade monomer 2.1 and the second blade monomer 2.2 are smaller than the wall ...

Embodiment 2

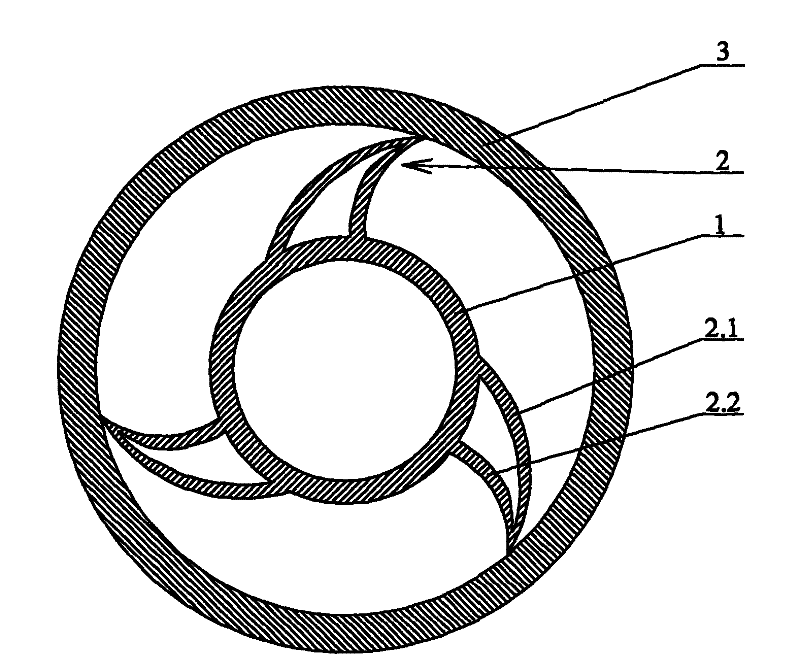

[0015] The rotating flexible shaft support tube with oblique triangular arc-shaped supporting blades in section includes three or more supporting blades 2 integrally arranged on the inner tube body 1 and the outer wall surface of the inner tube body 1, and the supporting blades 2 are inside The outer wall surface of the tube body 1 extends along the length direction of the inner tube body 1, the top end of the support blade 2 is clamped, the bottom end of the support blade 2 is stretched out, and the support blade 2 is composed of the first blade monomer 2.1 and the second blade The monomers 2.2 are formed by connecting the top parts, the bottom ends of the first blade monomer 2.1 and the second blade monomer 2.2 are connected with the outer wall of the inner tube body 1, and the first blade monomer 2.1 and the second blade monomer 2.2 The sections are all arc-shaped, the wall thicknesses of the first blade monomer 2.1 and the second blade monomer 2.2 are smaller than the wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com