Heat multiplication type hot site heat exchanger unit

A technology of heat exchange unit and heat station, applied in the field of heat exchange station, can solve the problem of large loss of available energy, and achieve the effects of reducing energy consumption in transmission and distribution, improving utilization rate, heat multiplying rate and energy saving rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

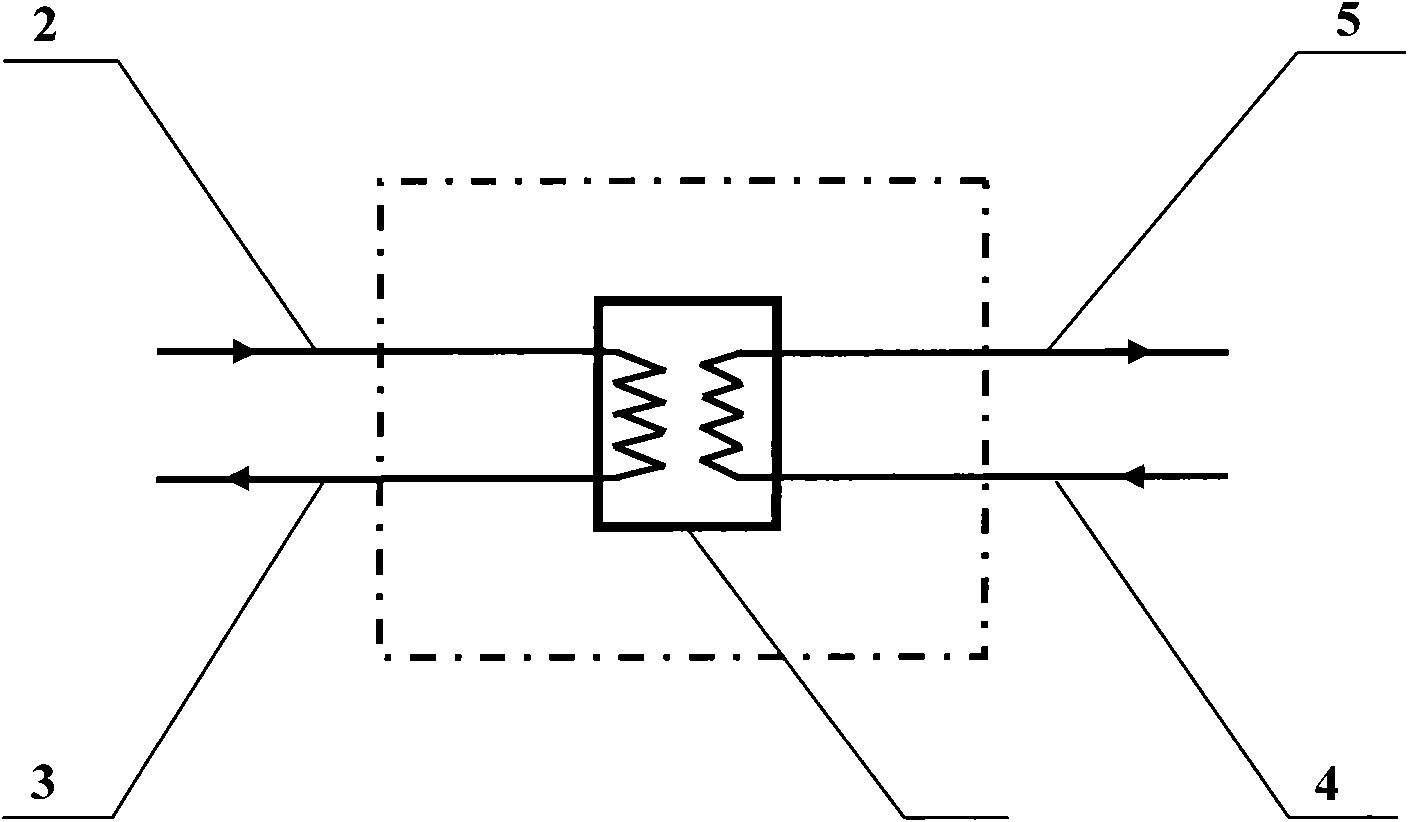

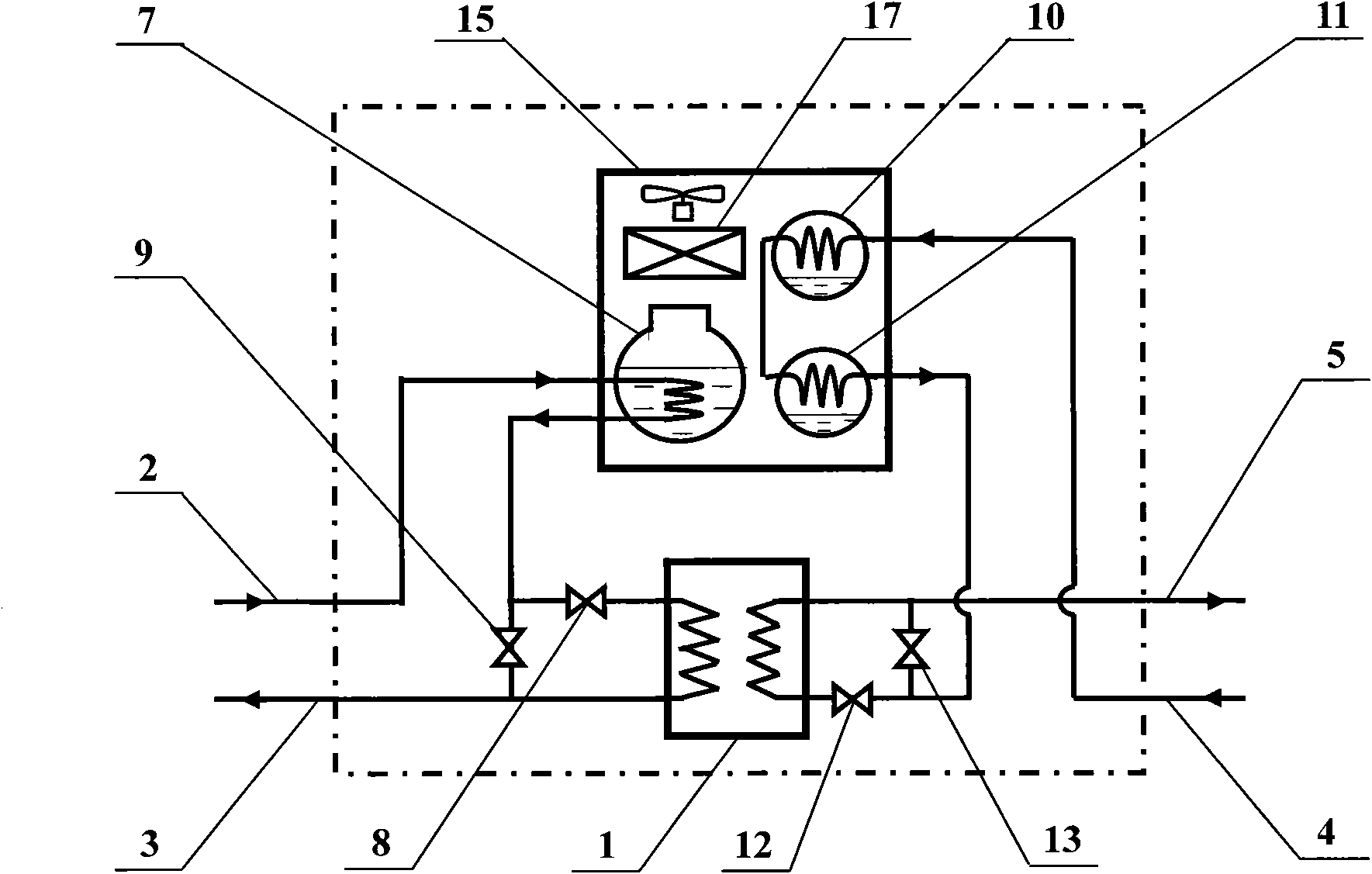

Embodiment 1

[0024] In this embodiment, hot water is used as the primary heat medium, and the absorption heat pump unit 6 adopts the absorption air source heat pump unit 15 . Such as figure 2 As shown, a heat multiplier heat station heat exchange unit includes a heat exchanger 1, a heat medium inlet pipe 2 on the primary side, a heat medium outlet pipe 3 on the primary side, a hot water inlet pipe 4 on the secondary side, and a hot water pipe on the secondary side The water outlet pipe 5 is characterized in that: the heat multiplication type heat station heat exchange unit also includes an absorption air source heat pump unit 15, and the absorption air source heat pump unit 15 includes a generator 7, an absorber 10, a condenser 11 and an air-cooled evaporator 17; the primary heat medium inlet pipe 2 is connected to the inlet pipe of the generator 7, and the outlet pipeline of the generator 7 is divided into two paths, one path passes through the first valve 8 and the heat exchange The pr...

Embodiment 2

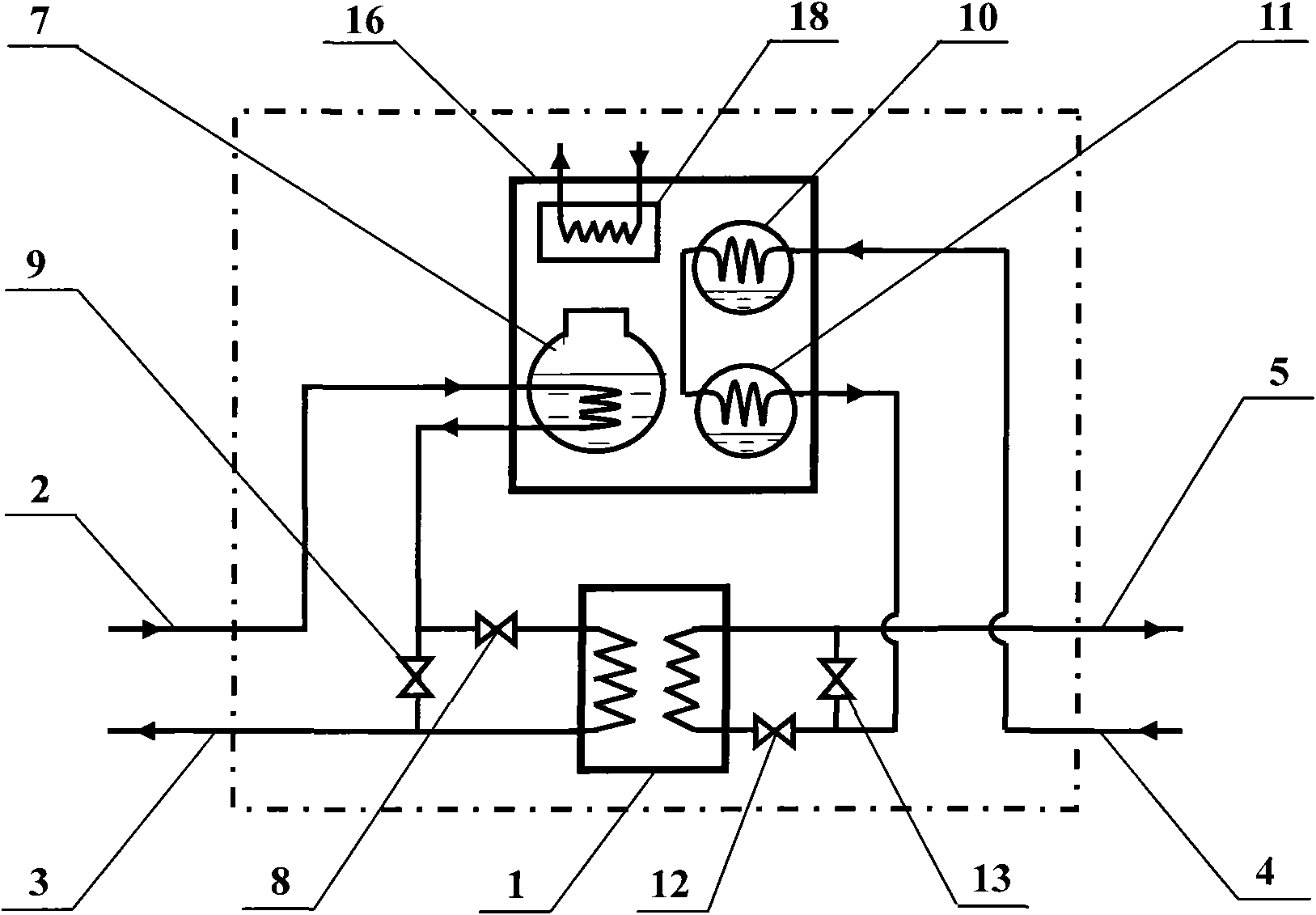

[0035] In this embodiment, hot water is used as the primary heat medium, and the absorption heat pump unit 6 adopts the absorption water source heat pump unit 16 . Such as image 3 As shown, a heat multiplier heat station heat exchange unit includes a heat exchanger 1, a heat medium inlet pipe 2 on the primary side, a heat medium outlet pipe 3 on the primary side, a hot water inlet pipe 4 on the secondary side, and a hot water pipe on the secondary side The water outlet pipe 5 is characterized in that: the heat multiplication type heat station heat exchange unit also includes an absorption water source heat pump unit 16, and the absorption water source heat pump unit 16 includes a generator 7, an absorber 10, a condenser 11 and Water-cooled evaporator 18; the primary heat medium inlet pipe 2 is connected to the inlet pipe of the generator 7, and the outlet pipe of the generator 7 is divided into two paths, one path passes through the first valve 8 and the heat exchanger 1 once...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com