Test device for scour resistance of base course

A technology for testing equipment and pavement base, which can be applied in the direction of removing certain components, such as weighing, etc., can solve the problems of complex equipment, difficult to popularize and use, etc., and achieve the effects of simple installation, simple and clear design ideas, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

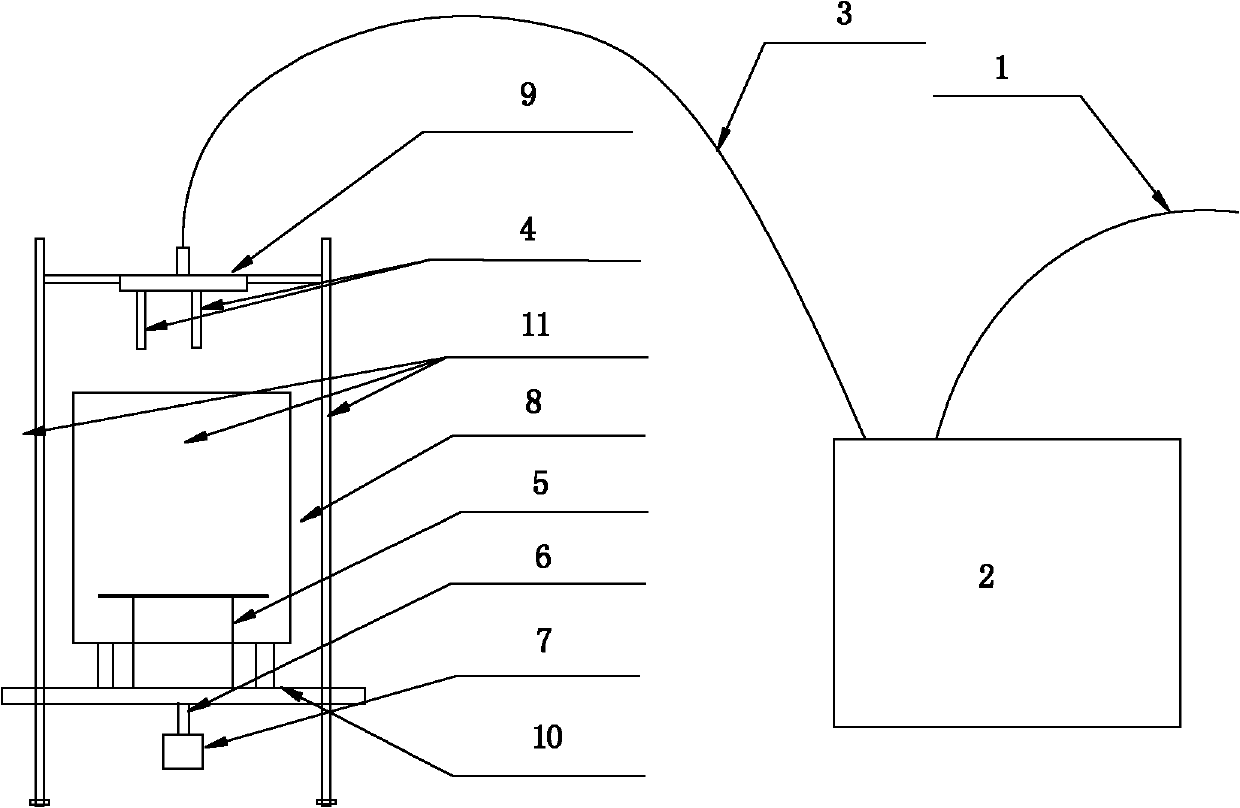

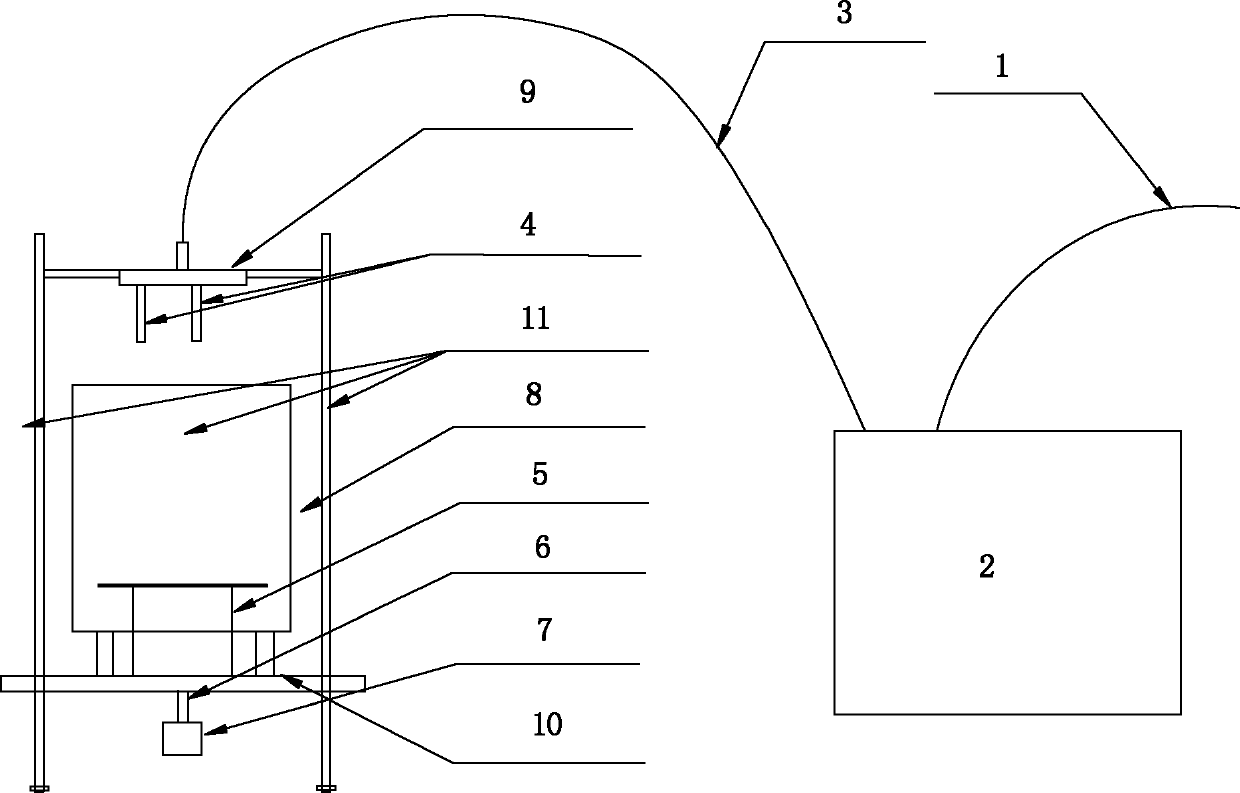

[0017] The invention mainly includes a hydraulic pressure component, a test component and a support component.

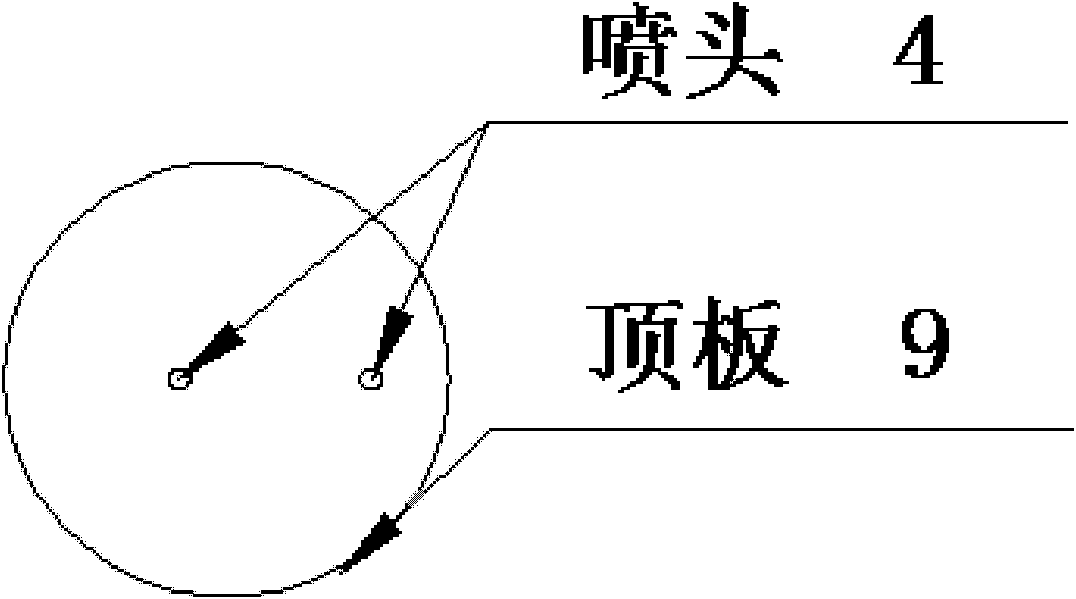

[0018] see figure 1 , The anti-scouring test instrument has a water pressure machine 2 to provide the dynamic water pressure required for the test. Water enters the water pressure machine 2 from the water inlet pipe 1, and after obtaining the pressure required for the test, it flows into the test part from the water outlet pipe 3 to perform the scouring test. The nozzle 4 is located on the top plate 9, and the instrument has two nozzles, from which a water column with a certain pressure is sprayed to hit the test piece placed on the rotating support 5. The motor 7 and the transmission shaft 6 drive the rotating support 5 to rotate at a certain speed, thereby driving the test piece on it to rotate, so that the top surface of the test piece is completely washed by the water column, so as to ensure the accuracy and validity of the data. After the test piece is washed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com