Method for manufacturing memory module by using defect list of electrically-erasable programmable read-only memory

A technology of memory module and manufacturing method, which is applied in read-only memory, static memory, information storage, etc., and can solve cumbersome and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention generally relates to an improved memory module fabrication. The following descriptions are used to enable those skilled in the art to implement and use the present invention, such as the implementation aspects and requirements described below, and various changes in the best embodiment can be easily known by those skilled in the art , and the general principles can be applied to other embodiments. Therefore, the embodiments of the present invention are not intended to limit the scope of the present invention, and the scope of rights of the present invention should be interpreted in the broadest manner based on the principles and features described herein.

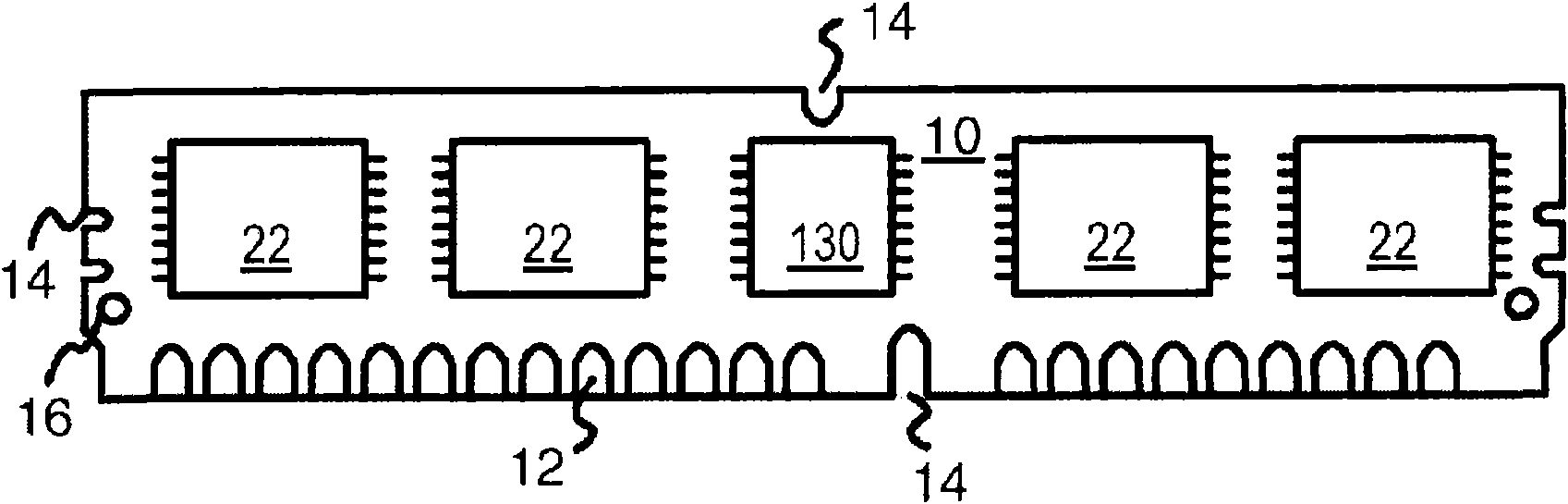

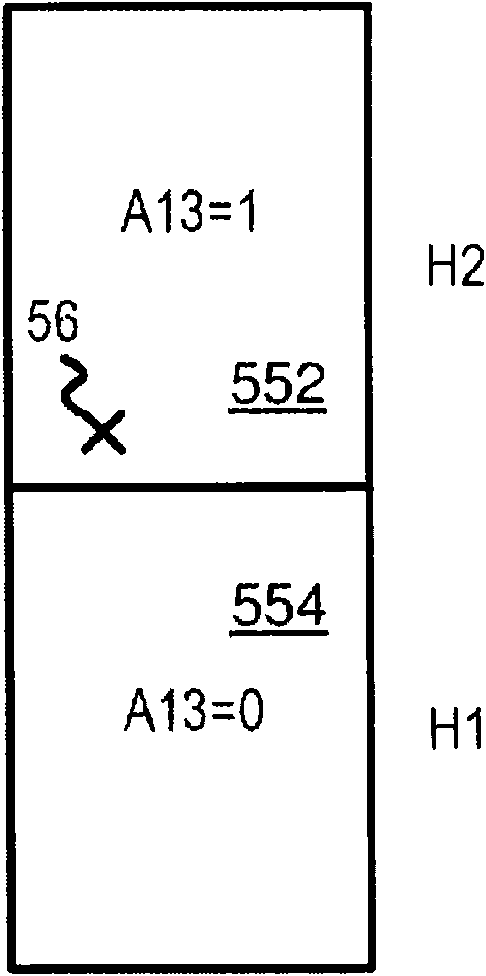

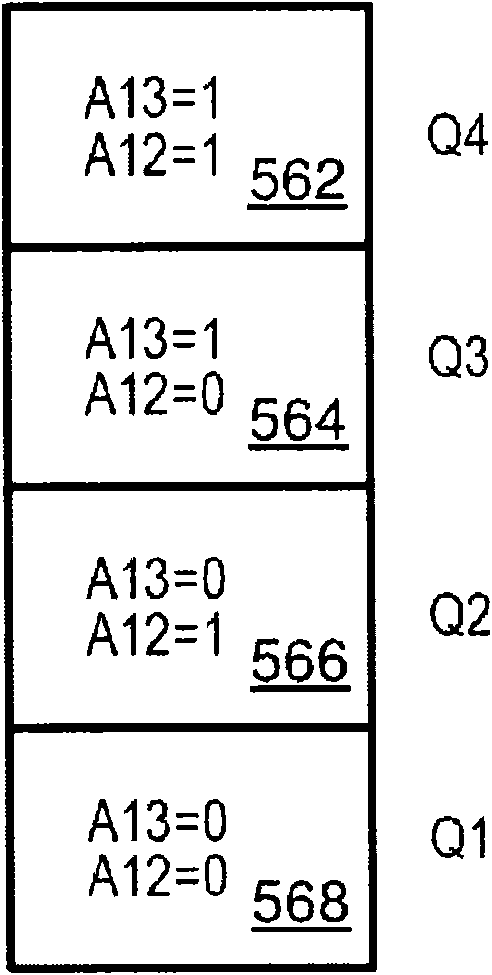

[0040] Figure 4 It is an inspection process that emphasizes burning-in assembled memory modules rather than individual parts of good DRAM chips. Good and partially good DRAM chips are packaged into packages, such as ball-grid-array (BGA) or thin-small outlinepackages (TSOP), and shipped to M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com