Front axle roll-forging finished blank mold of heavy-duty car

A technology of roll forging refined blanks and heavy vehicles, which is applied in the direction of manufacturing tools, forging/pressing/hammering machines, forging/pressing/hammer devices, etc. Affect product quality stability and other issues, to achieve the effect of improving the connection state, helping metal flow, and uniform plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The present invention is described in detail by taking the roll forging refined billet die of the front axle of the A680 type automobile as an example.

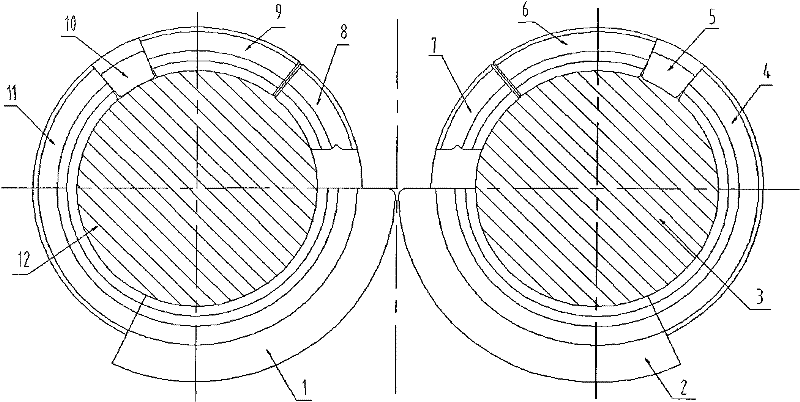

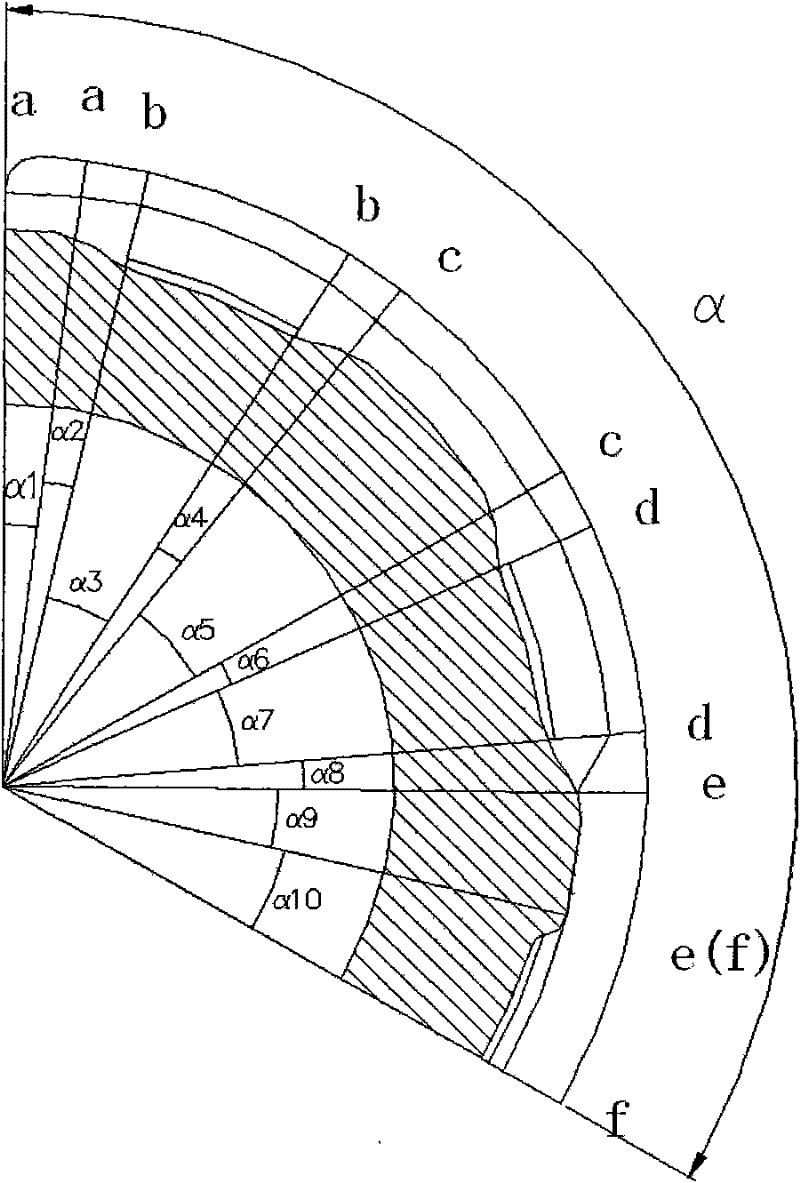

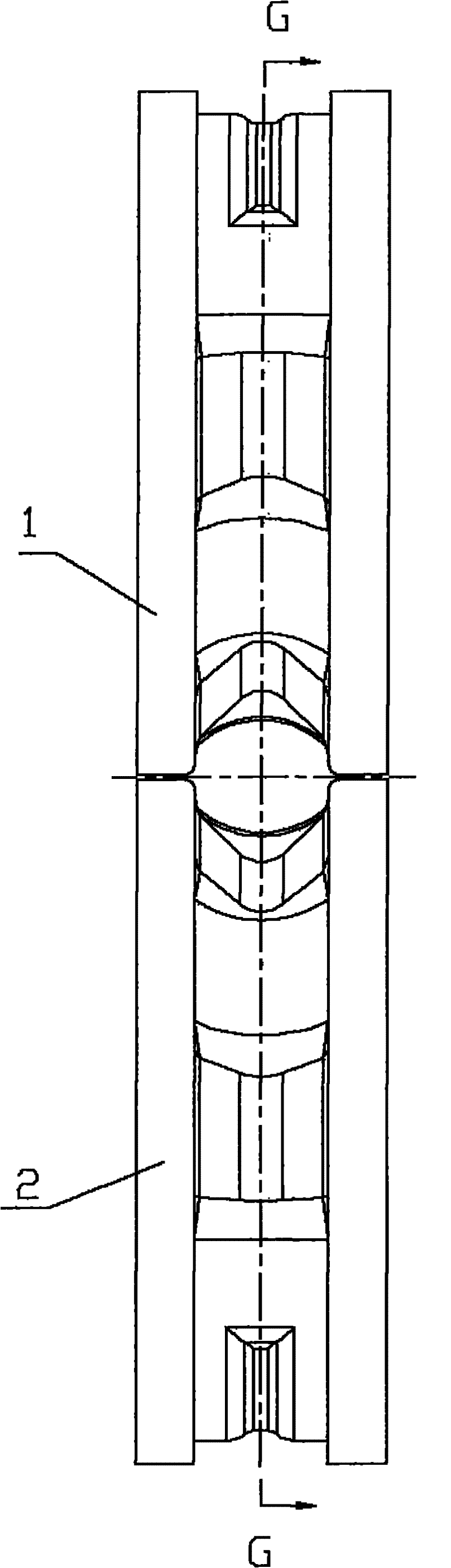

[0085] The mold includes an upper half mold and a lower half mold. The upper and lower half molds are symmetrically installed on the upper and lower rolls of the roll forging machine through the annular channel and the annular boss on the opposite surface respectively, and the upper and lower half molds The gap between them is 5mm, the central angle α of the upper and lower half molds is both 120°, the inner and outer radii and widths of the upper and lower half molds are 300mm, 495mm, and 265mm respectively, and the annular passage on one side of each half mold The inner and outer radii and groove depths of the grooves are 350mm, 399mm, and 8mm respectively, and the inner and outer radii and heights of the annular bosses on the other side of each mold half are 350mm, 399mm, and 8mm, respectively. There are 6 sections ...

Embodiment 2

[0087] The present invention is described in detail by taking the roll forging refined billet die of the front axle of the EQ142 type automobile as an example.

[0088] The mold includes an upper half mold and a lower half mold. The upper and lower half molds are symmetrically installed on the upper and lower rolls of the roll forging machine through the annular channel and the annular boss on the opposite surface respectively, and the upper and lower half molds The gap between them is 2mm, the central angle α of the upper and lower half molds is 109°, the inner and outer radii and widths of the upper and lower half molds are 260mm, 395mm, and 250mm respectively, and the ring on one side of each half mold The inner and outer radii and groove depths of the through groove are 310mm, 359mm, and 8mm respectively, and the inner and outer radii and heights of the annular bosses on the other side of each half mold are 310mm, 359mm, and 8mm, respectively. The upper and lower half molds...

Embodiment 3

[0090] The present invention is described in detail by taking the roll forging refined billet mold of the front axle of the YQ153A type automobile as an example.

[0091] The mold includes an upper half mold and a lower half mold. The upper and lower half molds are symmetrically installed on the upper and lower rolls of the roll forging machine through the annular channel and the annular boss on the opposite surface respectively, and the upper and lower half molds The gap between them is 5mm, the central angle α of the upper and lower half molds is both 120°, the inner and outer radii and widths of the upper and lower half molds are 300mm, 495mm, and 265mm respectively, and the annular passage on one side of each half mold The inner and outer radii and groove depths of the grooves are 350mm, 399mm, and 8mm respectively, and the inner and outer radii and heights of the annular bosses on the other side of each mold half are 350mm, 399mm, and 8mm, respectively. There are 6 sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com