Automatic conveyor

An automatic conveying and conveying platform technology, which is applied in the field of conveyors, can solve problems such as difficulty in satisfying the degree of automation, affecting the production cycle, and inability to manually load parts, etc., and achieves the effects of easy operation and maintenance, low cost and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

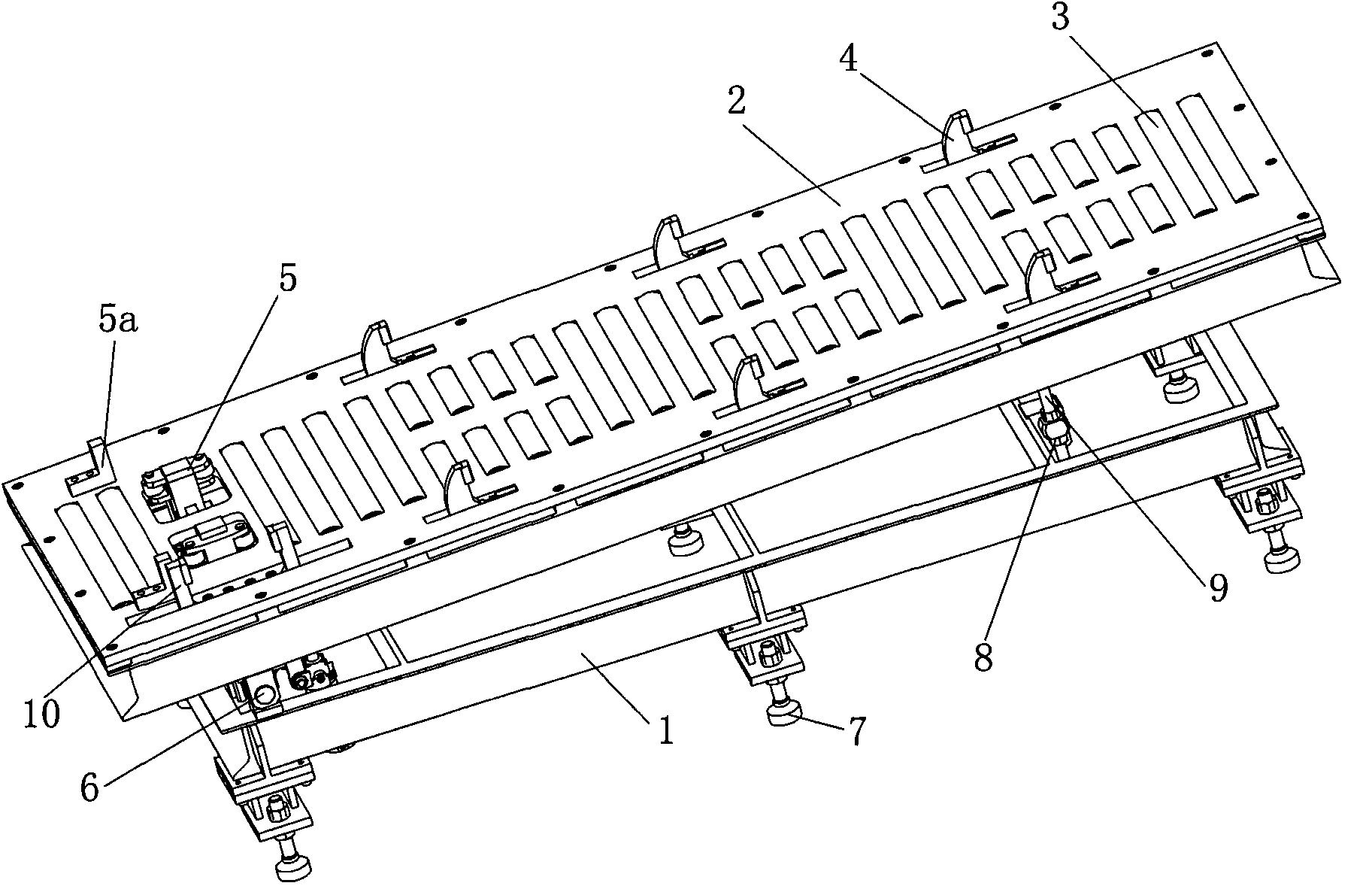

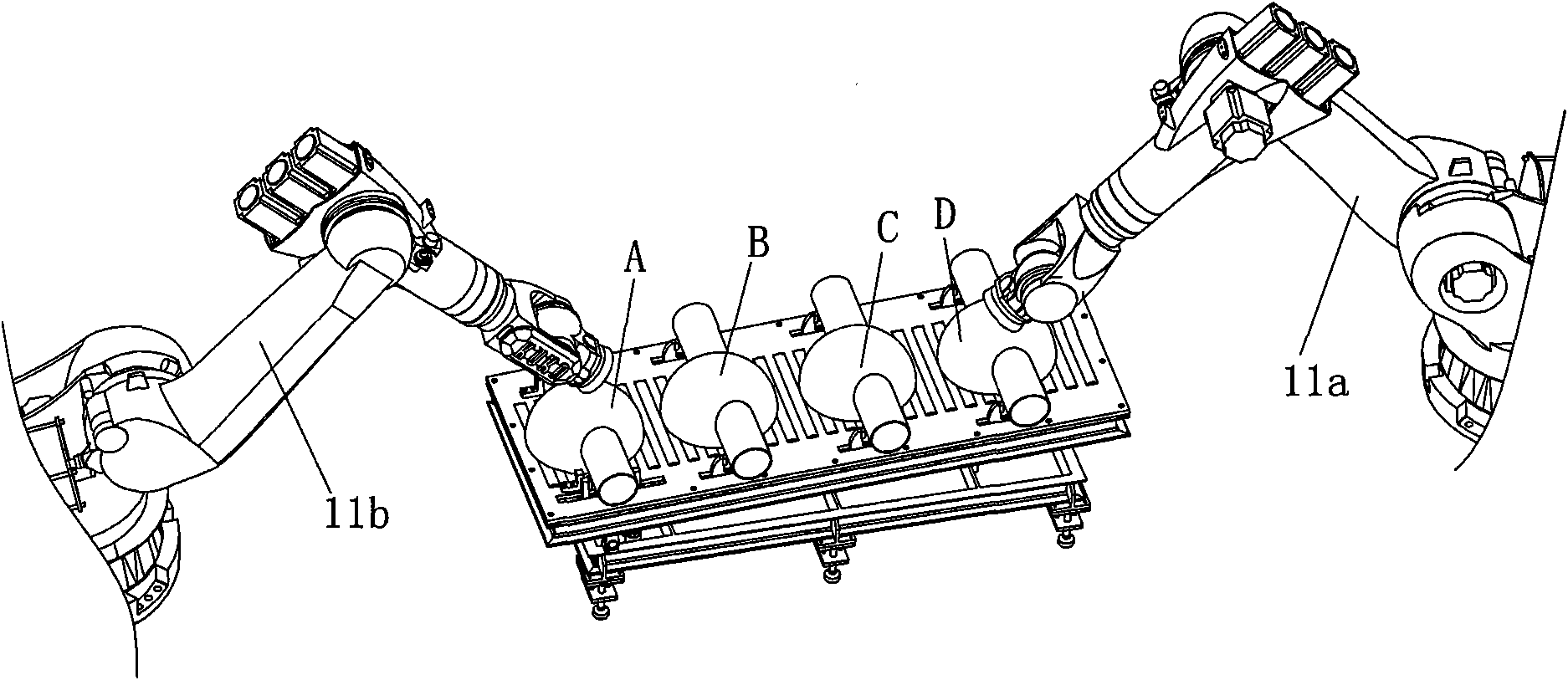

[0025] see figure 1 , figure 2 , with the base 1 as the support, the conveying platform 2 is set, and the conveying platform 2 is arranged in an inclined manner along the conveying direction with the upper end high and the lower end low, and the upper part robot 11a is at the higher end of the conveying platform; on the conveying platform 2 The rotatable support rollers 3 form the conveying plane, and the conveyed parts roll forward on the support rollers 3, which can effectively reduce the wear of the workpiece and make the conveying smoother.

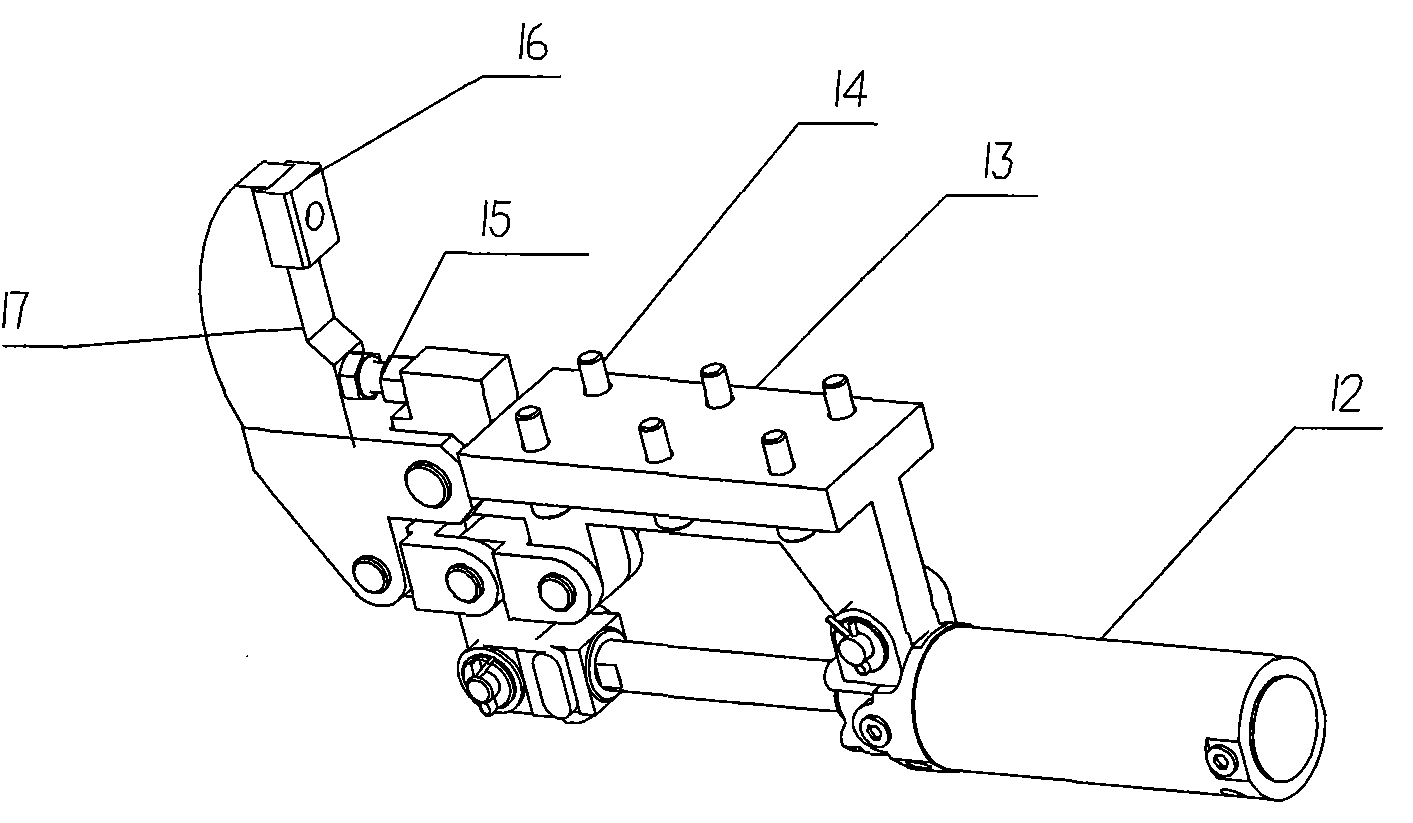

[0026] figure 1 As shown, various limit mechanisms that can be lifted and lowered in good time are set on the conveying platform 2, including the upper piece limit claw 4 at the upper piece position, the lower piece centering positioning card 5 at the lower piece position, and the clamping and positioning of the lower piece. Card 10, and each middle limit claw that is arranged at intervals between the upper piece position and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com